Solid state camellia seed oil rich in polyphenols and preparation method thereof

A kind of camellia oil and solid-state technology, which is applied in the field of preparation of solid-state camellia oil, can solve problems such as application, low freezing point, and difficult camellia oil, and achieve the effects of simple production process, improved quality, and increased benefit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

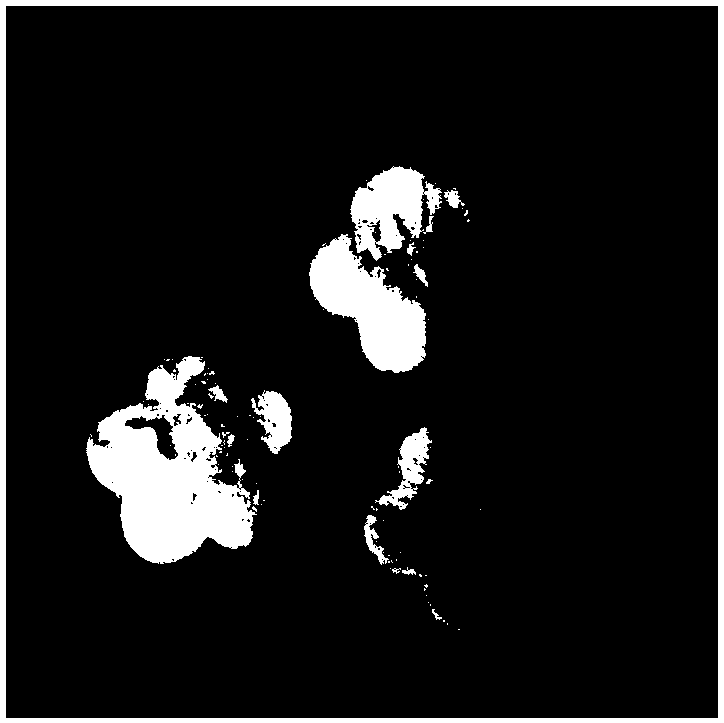

Image

Examples

Embodiment 1

[0038] The concrete preparation operation steps of a kind of solid tea oil rich in polyphenols are as follows:

[0039] Step 1 Preparation of particle dispersed phase

[0040] First, measure 100 ml of tea oil and place it in a beaker, heat it to 95 °C, and add 0.5 g of tea polyphenol palmitate and 1 g of glyceryl monopalmitate while stirring the tea oil at a speed of 1200 r / min. Until tea polyphenol palmitate and glyceryl monopalmitate dissolve completely, obtain the tea oil solution containing tea polyphenol palmitate and glyceryl monopalmitate; Under the condition of power of 500W and temperature of 50°C, ultrasonic treatment was performed for 25 min; then, the ultrasonically treated camellia oil solution was placed in liquid nitrogen and quickly frozen for 8 min to obtain completely frozen camellia oil; finally, the frozen camellia oil was Slowly melt into a liquid state at 25°C to obtain 94 ml particle dispersion phase containing tea polyphenol palmitate and glycerol mono...

Embodiment 2

[0049] The concrete preparation operation steps of a kind of solid tea oil rich in polyphenols are as follows:

[0050] Step 1 Preparation of particle dispersed phase

[0051] First, measure 2000 ml of tea oil and place it in a stirring tank, heat it to 98 ° C, and add 12 g of tea polyphenol palmitate and 26 g of monopalmitin while stirring the tea oil at a speed of 1000 r / min, Until tea polyphenol palmitate and glyceryl monopalmitate dissolve completely, obtain the tea oil solution containing tea polyphenol palmitate and glyceryl monopalmitate; Under the conditions of 400W power and 53°C, ultrasonic treatment was performed for 22 minutes; then, the tea oil solution after ultrasonic treatment was quickly frozen in liquid nitrogen for 10 minutes to obtain completely frozen camellia oil; finally, the frozen camellia oil was placed in Slowly melted into a liquid state at 22°C to obtain a particle dispersion phase of 1875 ml of tea polyphenol palmitate and glycerol monopalmitate....

Embodiment 3

[0060] The concrete preparation operation steps of a kind of solid tea oil rich in polyphenols are as follows:

[0061] Step 1 Preparation of particle dispersed phase

[0062] First, measure 6000 ml of tea oil and place it in a stirring tank, heat it to 100°C, and while stirring the tea oil at a speed of 800 r / min, add 30 g of tea polyphenol palmitate and 120 g of glyceryl monopalmitate until Tea polyphenol palmitate and glyceryl monopalmitate are completely dissolved to obtain a tea oil solution containing tea polyphenol palmitate and glyceryl monopalmitate; Under the conditions of 300W and 55°C, ultrasonic treatment was performed for 20 min; then, the ultrasonically treated camellia oil solution was quickly frozen in liquid nitrogen for 12 min to obtain completely frozen camellia oil; finally, the frozen camellia oil was placed in Slowly melt into a liquid state at 20°C to obtain a particle dispersion phase of 5580 ml of tea polyphenol palmitate and glycerol monopalmitate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com