Automobile electronic rearview mirror

A technology for automotive electronics and rearview mirrors, applied in the field of automotive rearview mirrors, can solve problems such as poor visual effects, and achieve the effects of reduced response time, good anti-glare effect, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

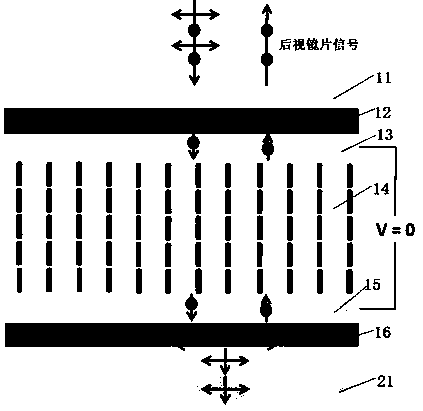

[0047] A kind of automobile electronic rearview mirror, comprises rearview mirror casing, the rearview lens 1 that is arranged on the rearview mirror casing and the liquid crystal display screen 2 that is arranged on rearview lens 1 back side, as figure 1 Shown: rearview lens 1 comprises glass cover plate 11, front glass substrate 13 and rear glass substrate 15, is provided with liquid crystal layer 14 between front glass substrate 13 and rear glass substrate 15, between front glass substrate 13 and rear glass substrate The outer sides of 15 are provided with front polarizer 12 and rear reflective polarizer 16 respectively, and glass cover plate 11 is arranged on the outer side of front polarizer 12; layer, the liquid crystal layer 14 is located between the liquid crystal alignment layer of the front glass substrate 13 and the rear glass substrate 15; the liquid crystal display 2 includes the front polarizer 21 of the liquid crystal display, the light source 22 of the liquid cr...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 lies in that the alignment modes of the liquid crystal molecules in the liquid crystal layer 14 are different.

[0061] In this embodiment, the arrangement mode of the liquid crystal molecules of the liquid crystal layer 14 includes a horizontal alignment mode, and the horizontal alignment mode refers to that in the initial state, the positive liquid crystal molecules in the liquid crystal molecules of the liquid crystal layer 14 are all nearly parallel to the front glass substrate 13 and the rear glass substrate 15 are arranged, that is, the negative liquid crystal molecules in the liquid crystal molecules are arranged at an angle of 0.5° to 2° or -0.5° to -2° with the front glass substrate 13 and the rear glass substrate 15 . Under the effect of the liquid crystal alignment layers of the front glass substrate 13 and the rear glass substrate 15, the projection directions of the positive liquid crystal molecules on ...

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 lies in that the alignment modes of the liquid crystal molecules in the liquid crystal layer 14 are different.

[0068] In this embodiment, the alignment mode of the liquid crystal molecules of the liquid crystal layer 14 includes a conventional twisted orientation mode, and the conventional twisted orientation mode refers to that in the initial state, the positive liquid crystal molecules in the liquid crystal molecules of the liquid crystal layer 14 are on the front glass substrate 13 and the rear glass substrate 15 are twisted and arranged at 90 degrees or -90 degrees. The projection of the positive liquid crystal molecules on the plane of the front glass substrate 13 forms an angle of 0 degree, 90 degree or -90 degree with the front polarizer 12 . In this mode, the optical path difference range of the liquid crystal layer 14 is 375nm≤∆nd≤575nm or 900nm≤∆nd≤1200nm. In this embodiment, the central value of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com