Steelmaking converter flue gas treatment device and method

A flue gas treatment and steelmaking converter technology, applied in the field of converter flue gas treatment, can solve problems such as unfavorable waste heat recovery, potential safety hazards, and easy explosion of mixed gas, and achieve the effect of avoiding explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

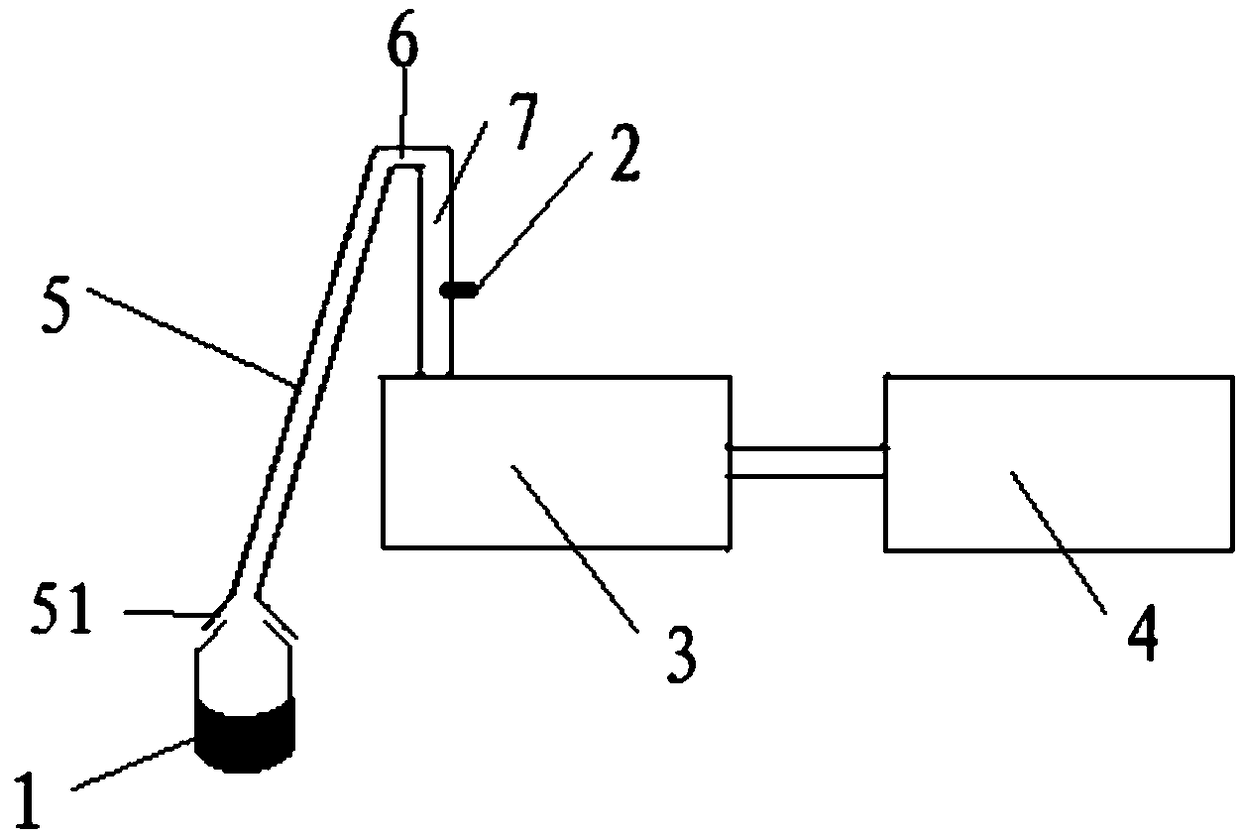

[0030] figure 1 It is a schematic structural diagram of a steelmaking converter flue gas treatment device in an embodiment of the present invention. Such asfigure 1 As shown, the flue gas treatment device includes:

[0031] The converter 1 has a furnace mouth on the top of the converter 1, and the flue gas produced in the smelting of the converter 1 overflows from the furnace mouth.

[0032] Specifically, a large amount of primary flue gas will be produced during the smelting process of the steelmaking converter, and the flue gas temperature is high and the dust content is high. The top furnace mouth overflows, the flue gas produced by the converter 1 can be cooled and recovered, and the waste heat in the low temperature section can be reused, so as to achieve effective utilization of resources and be conducive to environmental protection.

[0033] A flue, the inlet of the flue is connected to the furnace mouth, and vaporizes and cools the flue gas generated by the converter...

Embodiment 2

[0051] Figure 4 It is a schematic flow chart of a steelmaking converter flue gas treatment method in an embodiment of the present invention. A steelmaking converter flue gas treatment method provided in an embodiment of the present invention is applied to the flue gas treatment device, such as Figure 4 As shown, the method includes:

[0052] Step 10: The high-temperature dusty flue gas generated by the converter 1 during the smelting process enters the flue for vaporization and cooling.

[0053] Specifically, steelmaking converter 1 produces a large amount of flue gas during the smelting process, the temperature of the flue gas is 1500-1700°C, and the flue gas contains a large amount of dust, with a dust content of 100g / m 3 Left and right, the flue gas will overflow from the furnace mouth of the converter 1 into the flue, and gradually vaporize and cool the flue gas and recover heat by moving in the flue.

[0054] Step 20: When the flue gas in the flue cools down to 600-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com