A kind of polylactic acid foam material with nano cells and preparation method thereof

A foam material and polylactic acid technology, applied in the field of polylactic acid foam materials, can solve the problems of unfavorable PLA nano-foam preparation, cell merging, cell size increase, etc. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The polylactic acid foam material with nano-cells of embodiment 1, comprises the component of following quality:

[0059] Polylactic acid resin 59.937g;

[0060] Epoxy chain extender 0.06g;

[0061] Hydroxy-functionalized graphene (HG) 0.003g.

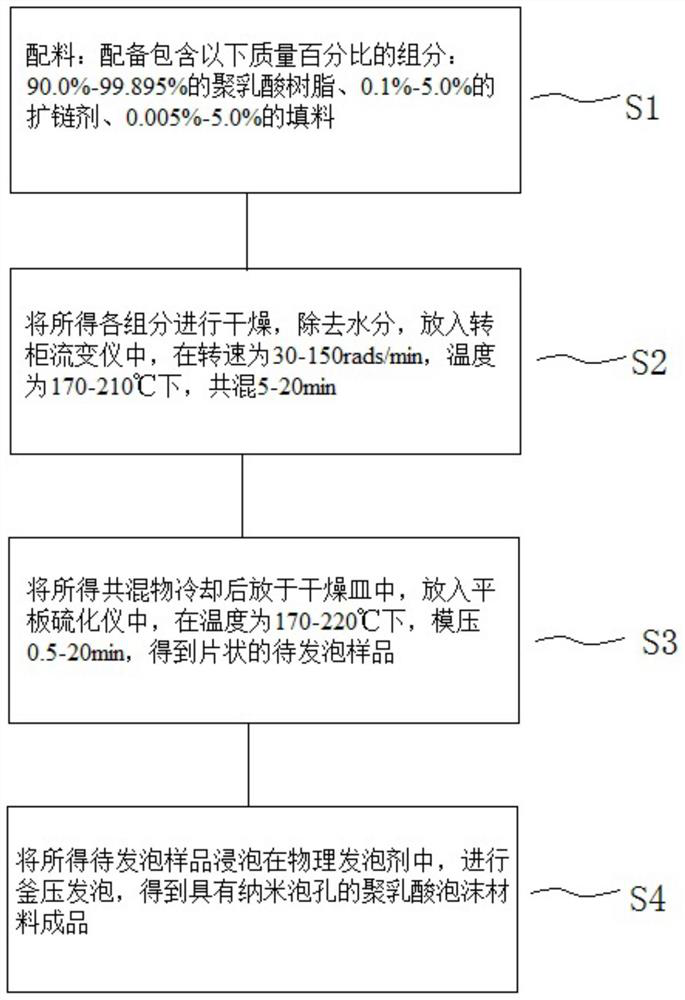

[0062] Such as figure 1 Shown, the preparation process of the polylactic acid foam material with nano-cell of embodiment 1 is as follows:

[0063] S1: Ingredients: equipped with the following components: 59.937g polylactic acid resin, 0.06g epoxy-based chain extender, 0.003g hydroxyl-functionalized graphene (HG);

[0064] S2. Dry the components obtained in step S1, put the components into a rotary cabinet rheometer for melting and blending, the melting temperature is 190 ° C, the rotation speed is 60 rads / min, and after blending for 15 minutes, a polymer with high melt strength is formed. Lactic acid blend;

[0065] S3. Cool the blend obtained in step S2, and use a flat plate rheometer to mold at a molding temperature of 19...

Embodiment 2

[0068] The polylactic acid foam material with nano-cells of embodiment 2, comprises the component of following quality:

[0069] Polylactic acid resin 57g;

[0070] Anhydride chain extender 1.5g;

[0071] Hydroxy-functionalized graphene (HG) 1.5g.

[0072] Such as figure 1 Shown, the preparation process of the polylactic acid foam material with nano-cell of embodiment 2 is as follows:

[0073] S1: Ingredients: equipped with the following components: 57g polylactic acid resin, 1.5g anhydride chain extender, 1.5g hydroxyl-functionalized graphene (HG);

[0074] S2. Dry the components obtained in step S1, put the components into a rotary cabinet rheometer for melting and blending, the melting temperature is 190 ° C, the rotation speed is 60 rads / min, and after blending for 15 minutes, a polymer with high melt strength is formed. Lactic acid blend;

[0075] S3. Cool the blend obtained in step S2, and use a flat plate rheometer to mold at a molding temperature of 190°C for 20 m...

Embodiment 3

[0078] The polylactic acid foam material with nano-cells of embodiment 3, comprises the component of following quality:

[0079] Polylactic acid resin 54g;

[0080] Isocyanate chain extender 3g;

[0081] Cage polysilsesquioxane (POSS) 3g.

[0082] Such as figure 1 Shown, the preparation process of the polylactic acid foam material with nano-cell of embodiment 3 is as follows:

[0083] S1: Ingredients: equipped with the following components: 54g polylactic acid resin, 3g isocyanate chain extender, 3g cage polysilsesquioxane (POSS);

[0084] S2. Dry the components obtained in step S1, put the components into a rotary cabinet rheometer for melting and blending, the melting temperature is 170 ° C, the rotation speed is 80 rads / min, and after blending for 10 minutes, a polymer with high melt strength is formed. Lactic acid blend;

[0085] S3. Cool the blend obtained in step S2, and use a flat plate rheometer to mold at a molding temperature of 200°C for 10 minutes to prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com