Method of preparing self-driving gradient-composition hydrogel through supergravity and application of the hydrogel

A composite hydrogel, self-driving technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of self-driving gradient structure composite hydrogel, complex preparation process, etc., and achieve high application value and practicality. The effect of operability, wide applicability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

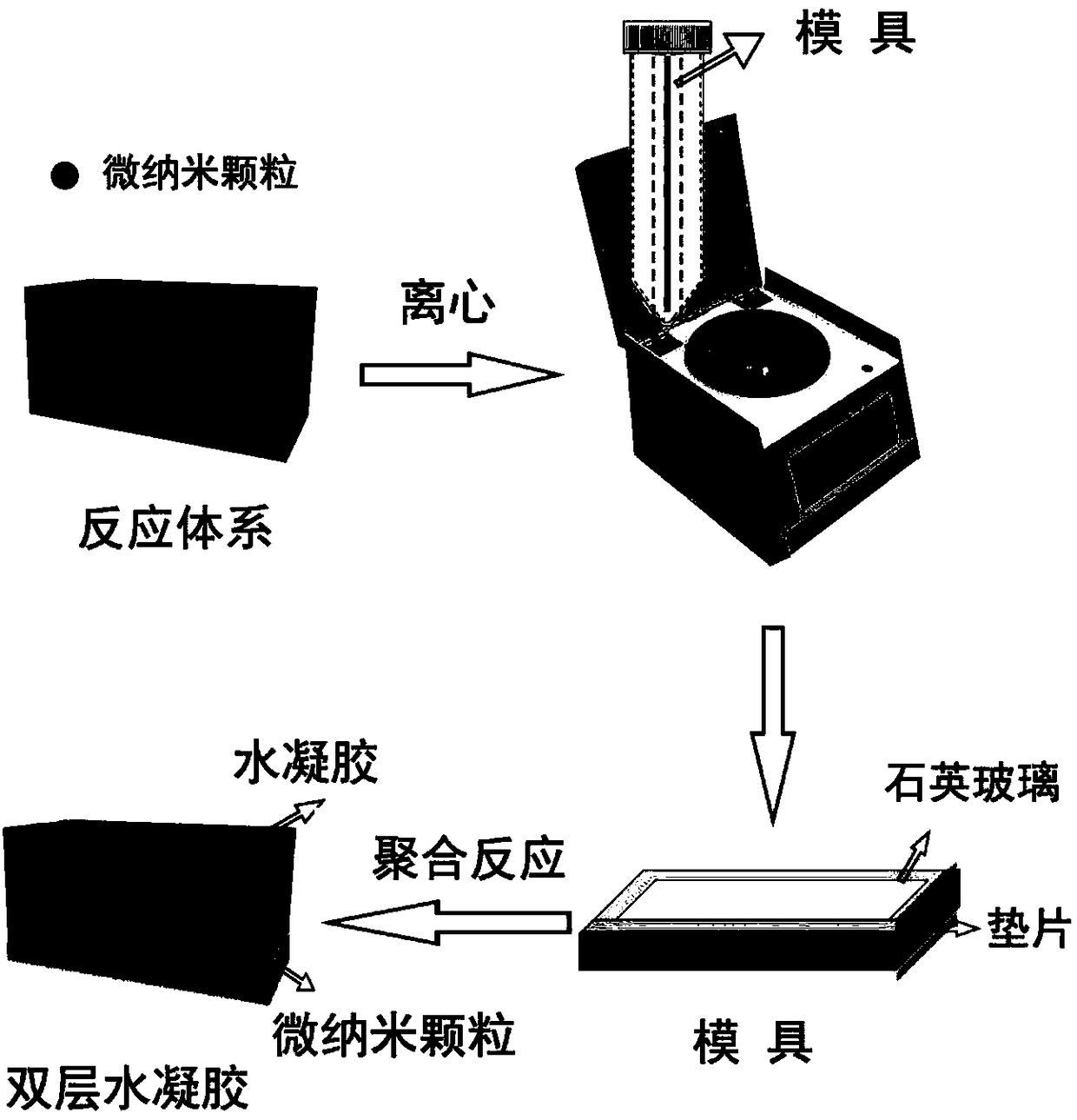

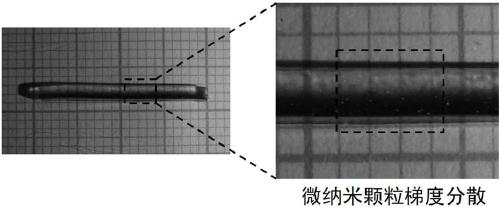

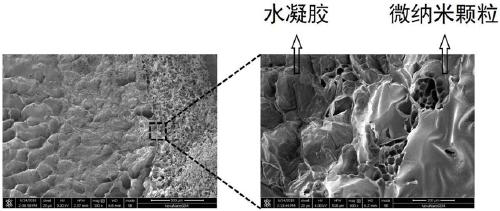

[0038] Take 0.001g graphene oxide (GO) and disperse it in 0.5g deionized water, sonicate it for 30min at room temperature to make it fully dispersed; then take 0.113g N-isopropylacrylamide (NIPAM) and dissolve it in 0.5g deionized water, and Add the uniformly dispersed GO mixture into the NIPAM solution, and continue to sonicate for 15 minutes; then add 1.08mg potassium persulfate (KPS) and 0.375mg N,N-methylenebisacrylamide (MBAA) and sonicate until dissolved, and put it in an ice-water bath After standing still for 15 minutes, add 20 μL N,N,N',N'-tetramethylethylenediamine (TEMED), shake evenly, put it in an ice-water bath, and inject it into the mold after 5 minutes. The mold is made of two layers of quartz glass and The PTFE hollow gasket with a thickness of 0.1 mm was centrifuged for 1 min at a centrifugation speed of 4000 r / min; finally, the mold was taken out and left to stand for 12 h to obtain a poly NIPAM / GO gradient composite hydrogel.

[0039]The flow chart of prep...

Embodiment 2

[0041] Take 0.003g of graphene oxide (GO) and disperse it in 0.5g of deionized water, and ultrasonically 30min at room temperature to make it fully dispersed; then take 0.113g of N-isopropylacrylamide (NIPAM) and dissolve it in 0.5g of deionized water, and Add the uniformly dispersed GO mixture into the NIPAM solution, continue to sonicate for 15 minutes, then add 1.08mg potassium persulfate (KPS) and 0.375mg N,N-methylenebisacrylamide (MBAA) sonicate until dissolved, and put it in an ice-water bath After standing still for 15 minutes, add 20 μL N,N,N',N'-tetramethylethylenediamine (TEMED), shake evenly, put it in an ice-water bath, and inject it into the mold after 5 minutes. The mold is made of two layers of quartz glass and The PTFE hollow gasket with a thickness of 0.1 mm was centrifuged for 1 min at a centrifugation speed of 4000 r / min; finally, the mold was taken out and left to stand for 12 h to obtain a poly NIPAM / GO gradient composite hydrogel.

Embodiment 3

[0043] Take 0.005g graphene oxide (GO) and disperse it in 0.5g deionized water, ultrasonic 30min at room temperature to make it fully dispersed; then take 0.113g N-isopropylacrylamide (NIPAM) and dissolve it in 0.5g deionized water, Add the uniformly dispersed GO mixture into the NIPAM solution, continue to sonicate for 15 minutes, then add 1.08mg potassium persulfate (KPS) and 0.375mg N,N-methylenebisacrylamide (MBAA) sonicate until dissolved, and put it in an ice-water bath After standing still for 15 minutes, add 20 μL N,N,N',N'-tetramethylethylenediamine (TEMED), shake evenly, put it in an ice-water bath, and inject it into the mold after 5 minutes. The mold is made of two layers of quartz glass and The PTFE hollow gasket with a thickness of 0.1 mm was centrifuged for 1 min at a centrifugation speed of 4000 r / min; then the mold was taken out and left to stand for 12 h to obtain a poly NIPAM / GO gradient composite hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com