Production system and method of abdominal pad with X-ray tracing line

A production system and abdominal pad technology, applied in the direction of absorbent pads, transportation and packaging, winding strips, etc., can solve the problems of substandard product quality, uniform product specifications, heavy workload, etc., to improve production efficiency and product specifications Uniform, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

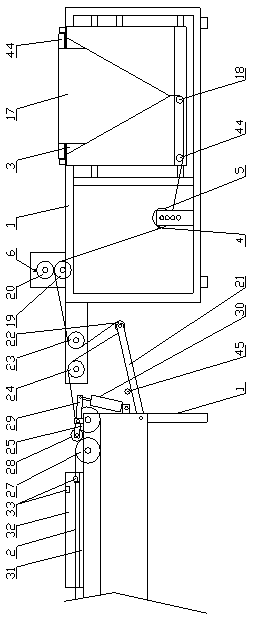

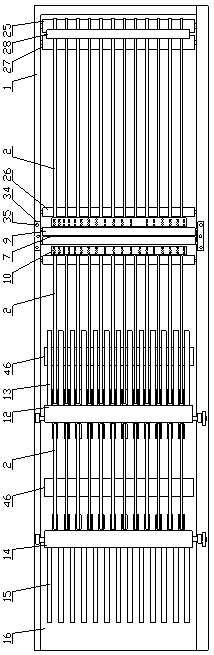

[0044] see Figure 1-10 , Embodiment 1 provides a production system for abdominal pads with an X-tracking line, the system includes a frame 1 and a folding and hemming device, a cloth storage device, a front conveying device, a distribution device, and Edge cutting device, rear conveying device, flap folding device, unloading conveying device, flap unloading device and unloading platform 16 etc., unloading platform 16 is located at the rear bottom of unloading conveying device and can stack belly pad.

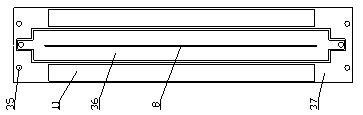

[0045] Among them, see figure 2 , the front conveying device, the rear conveying device and the unloading conveying device in this embodiment are all arranged along the front and rear direction and are located on the same horizontal plane, and they all include a plurality of conveyor belts 2 arranged side by side, and the width of the conveyor belt 2 is relatively small. , usually 2-4cm. The first drive roller 19 at the front portion of the conveying device is provided with ...

Embodiment 2

[0063] see Figure 1-11 , embodiment 2 provides a kind of production method of the abdominal pad with X tracking line, and this method adopts the system that embodiment 1 provides to produce abdominal pad, and this method comprises the following steps:

[0064] S101 Fabric loading: Output the gauze 17 to the V-shaped folding plate 3 using the fabric loading structure, and use a special loom to obtain gray fabric (roll shape) with X tracking lines.

[0065] S102 Fold in half once: use V-shaped folding board 3 to fold the gauze 17 along the width direction, when folding, the width of one layer is 2-4cm wider than the other layer (width of edge wrapping).

[0066] S103 One-time hemming: Use the folding rod 4 and the hemming guide roller 5 to hemm the gauze 17, and fold the extra 2-4 cm of one layer inwards and wrap it on another layer to realize hemming.

[0067] S104 Rolling traction: using the rolling structure 6 to roll the folded gauze 17 and convey it backward.

[0068] S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com