On-machine compensation method for large gear hobbing pitch error based on harmonic decomposition

A technology of tooth pitch error and compensation method, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of large gear mass, difficult repeated clamping, troublesome operation, etc., and achieves low cost and easy operation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

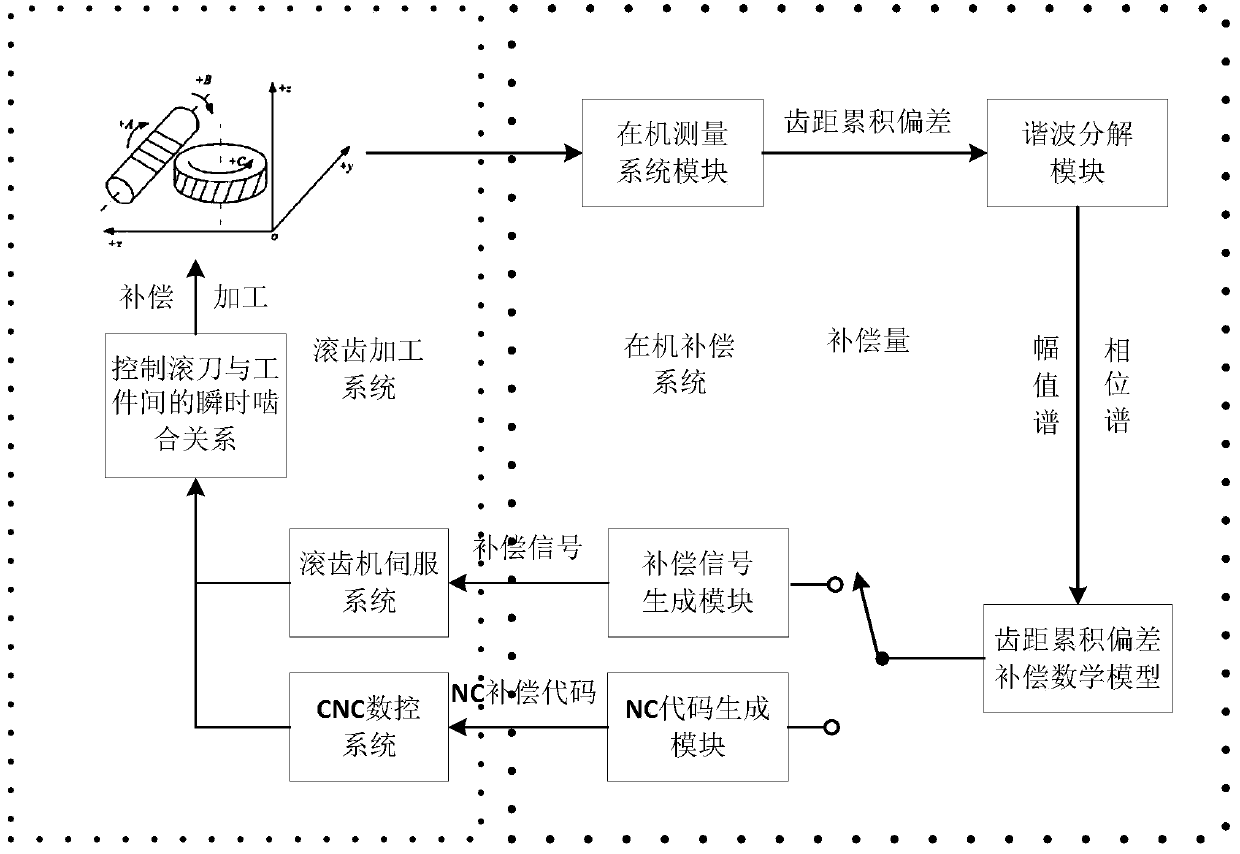

Embodiment 1

[0041] Embodiment 1: Changing the rotational speed of the rotary table of the machine tool to compensate for the gear hobbing pitch error, specifically includes the following steps:

[0042] 1) Through the on-machine measurement of the gear with machining allowance, the accumulative deviation data F of the tooth pitch of the gear is obtained pki

[0043] [F pki ] i = 1, 2, 3, ..., z (1)

[0044] That is to say, the accumulative deviation F of the pitch of k teeth pk ;

[0045] 2) The data measured in 1) are harmonically decomposed by discrete Fourier transform, and the amplitude spectrum and phase spectrum are obtained

[0046]

[0047] In the formula, A n is the amplitude of the Nth harmonic, is the phase angle of the Nth harmonic;

[0048] 3) Use the mathematical compensation model of cumulative tooth pitch deviation to solve the error compensation amount (that is, the variable C of the rotational speed of the rotary table of the machine tool p ),Proceed as follows...

Embodiment 2

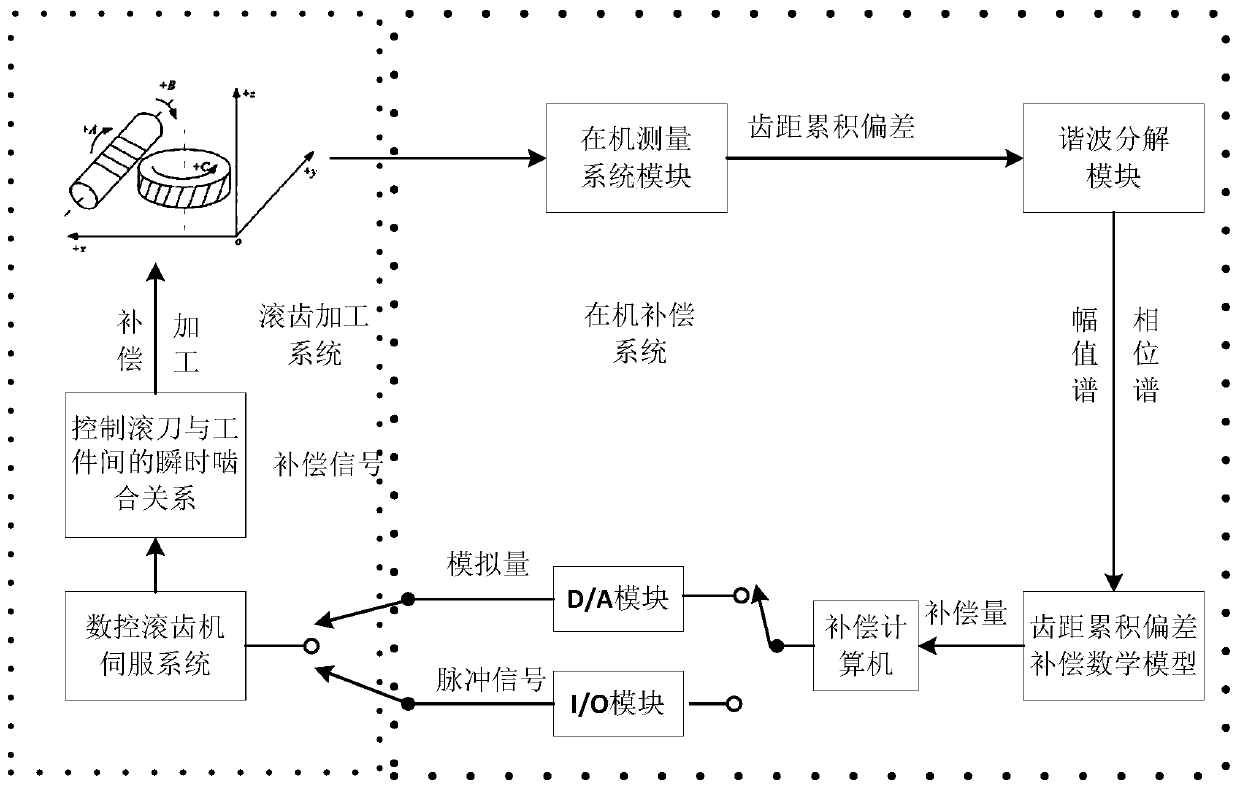

[0058] Embodiment 2: Changing the speed of the hob to compensate the pitch error of the hobbing process, which specifically includes the following steps:

[0059] 1) Through the on-machine measurement of the gear with machining allowance, the accumulative deviation data F of the tooth pitch of the gear is obtained pki

[0060] [F pki ] i = 1, 2, 3, ..., z (1)

[0061] That is to say, the accumulative deviation F of the pitch of k teeth pk ;

[0062] 2) The data measured in 1) are harmonically decomposed by discrete Fourier transform, and the amplitude spectrum and phase spectrum are obtained

[0063]

[0064] In the formula, A n is the amplitude of the Nth harmonic, is the phase angle of the Nth harmonic;

[0065] 3) Use the mathematical compensation model of cumulative tooth pitch deviation to solve the error compensation amount (that is, the variable C of the hob speed g ),Proceed as follows:

[0066] ① Take out the amplitude A by filtering n Amplitude greater ...

Embodiment 3

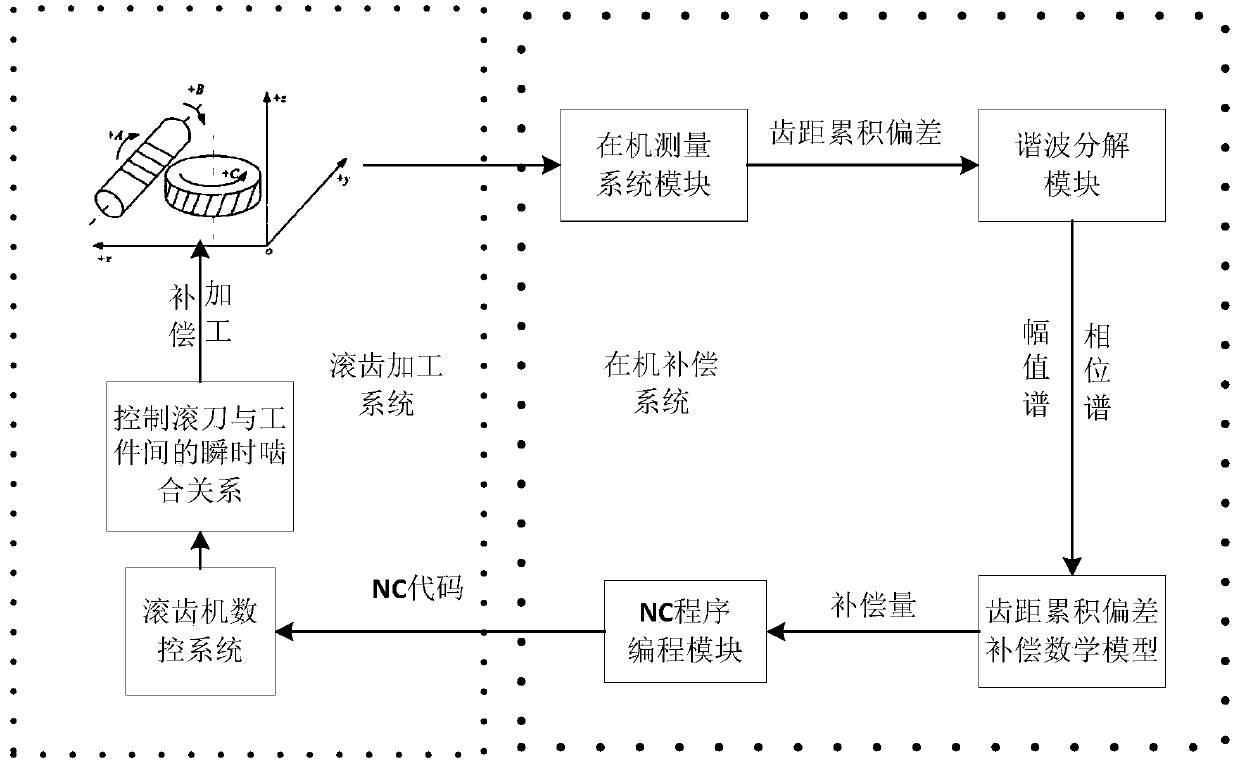

[0076] Embodiment 3: Compensating the pitch error of gear hobbing through the periodic axial movement of the hob, specifically including the following steps:

[0077] 1) Through the on-machine measurement of the gear with machining allowance, the accumulative deviation data F of the tooth pitch of the gear is obtained pki

[0078] [F pki ] i = 1, 2, 3, ..., z (1)

[0079] That is to say, the accumulative deviation F of the pitch of k teeth pk ;

[0080] 2) The data measured in 1) are harmonically decomposed by discrete Fourier transform, and the amplitude spectrum and phase spectrum are obtained

[0081]

[0082] In the formula, A n is the amplitude of the Nth harmonic, is the phase angle of the Nth harmonic;

[0083] 3) Using the mathematical compensation model for cumulative tooth pitch deviation, the error compensation amount (that is, the hob axial periodic motion amount C gz ),Proceed as follows:

[0084] ① Take out the amplitude A by filtering n Amplitude g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com