Machining method for stepped inner hole of shaft section

A processing method and shaft section technology, which are applied in the processing field of inner holes of steps, can solve the problems of easy deviation, the second blind hole and the third blind hole cannot maintain a high coaxiality through holes, and it is difficult to process, so as to achieve the guarantee The effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

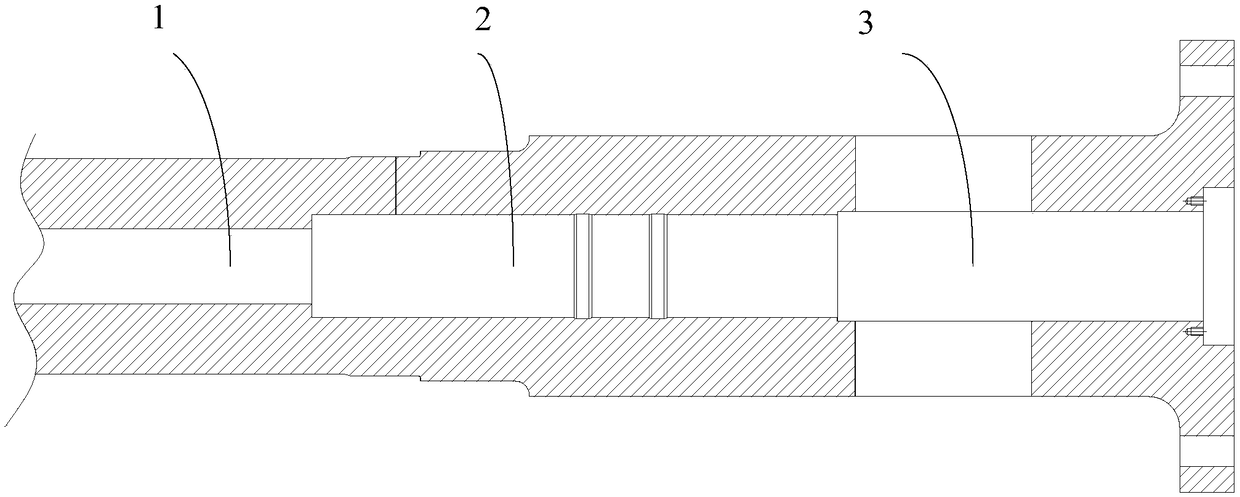

[0042] The embodiment of the present invention provides a processing method for the stepped inner hole of the shaft section, the processing method is used for processing such as figure 1 The stepped inner hole of the shaft section shown, the stepped inner hole includes a through hole 1 with an inner diameter of 110mm, a first blind hole 2 with an inner diameter of 150mm, and a second blind hole 3 with an inner diameter of 160mm. The design requires through holes 1, first Both the blind hole 2 and the second blind hole 3 are arranged coaxially with the outer circle of the shaft section.

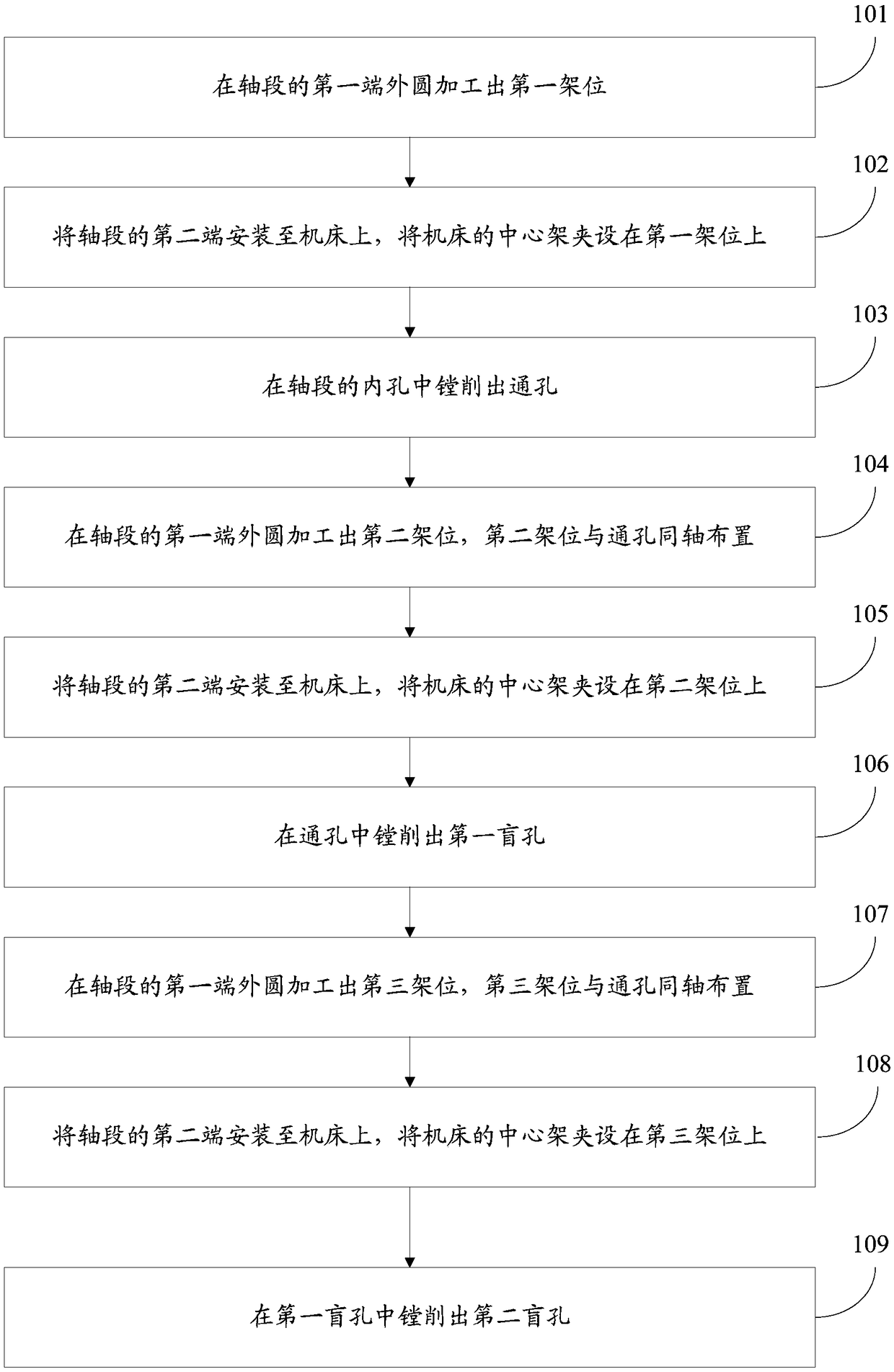

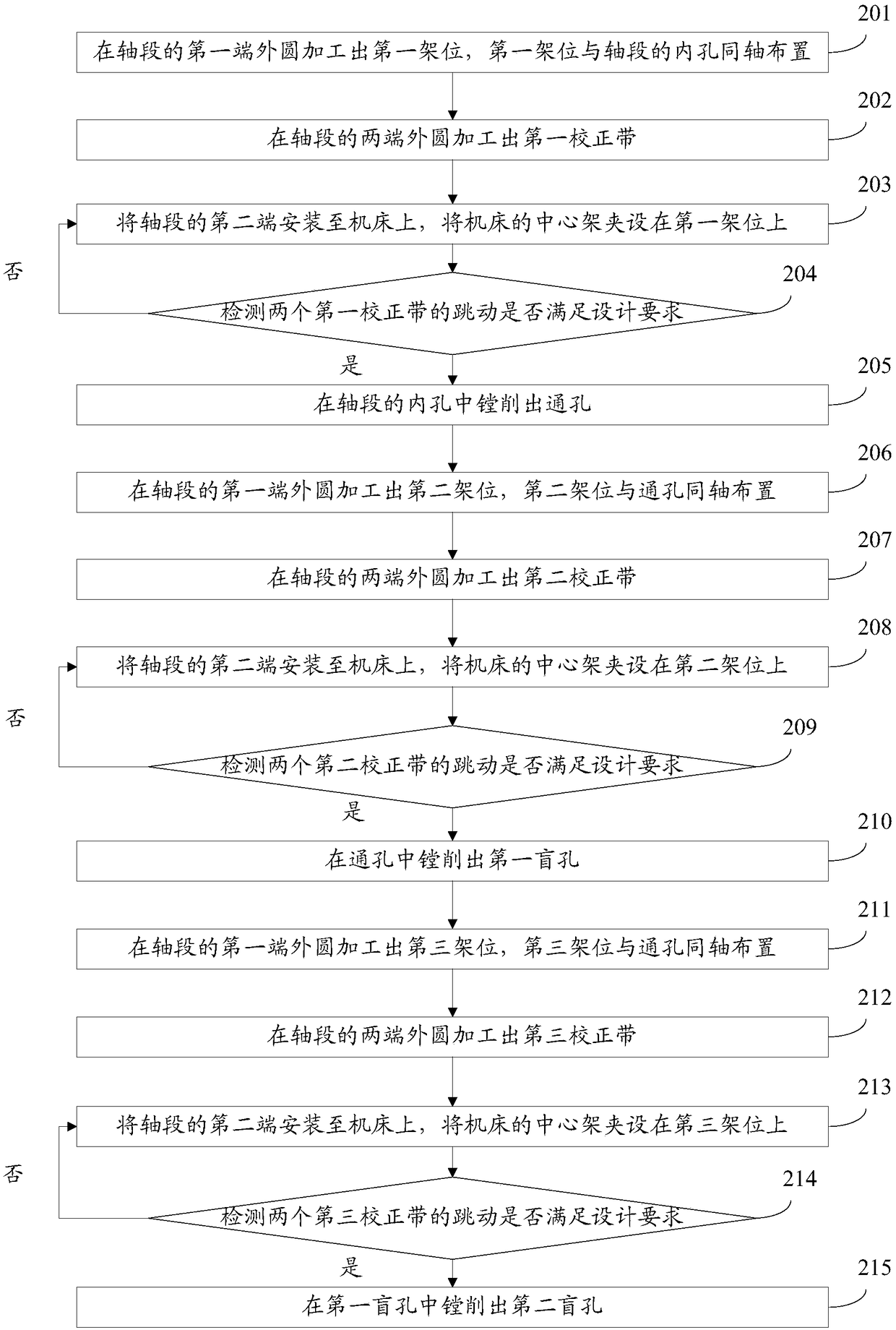

[0043] figure 2 is the flow chart of the processing method, such as figure 1 As shown, the processing method includes:

[0044] Step 101: Machinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com