A method for increasing that maximum output power of an IPM motor control of an electric vehicle

A technology of maximum output power and motor controller, which is applied in the direction of motor generator control, motor control, AC motor control, etc., can solve the problems of limited output power improvement and influence on motor operation performance, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

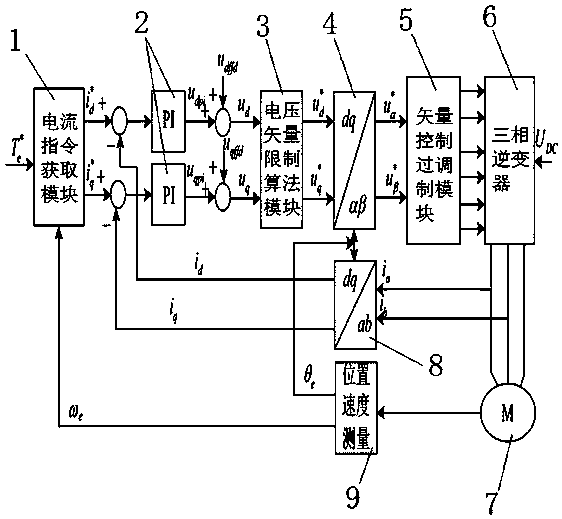

[0075] Example figure 1 As shown, the present invention is used to improve the method for the maximum output power of the electric vehicle IPM motor controller, and the motor controller is sequentially connected with a current command acquisition module 1, a proportional integral controller 2, a voltage vector limiting algorithm module 3, and a coordinate inverse conversion module 4. The vector control overmodulation module 5 and the three-phase inverter 6 drive the motor 7, the output signal of the three-phase inverter 6 is fed back to the proportional integral controller 2 through the coordinate conversion module 8, and the position and speed signals of the motor 7 are measured by the position and speed Module 9 feeds back to the current command acquisition module 1, coordinate inverse conversion module 4 and coordinate conversion 8 respectively, where the current command acquisition module 1 inputs the given torque of the motor in the full speed range This method comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com