Method for injecting liquid into a battery

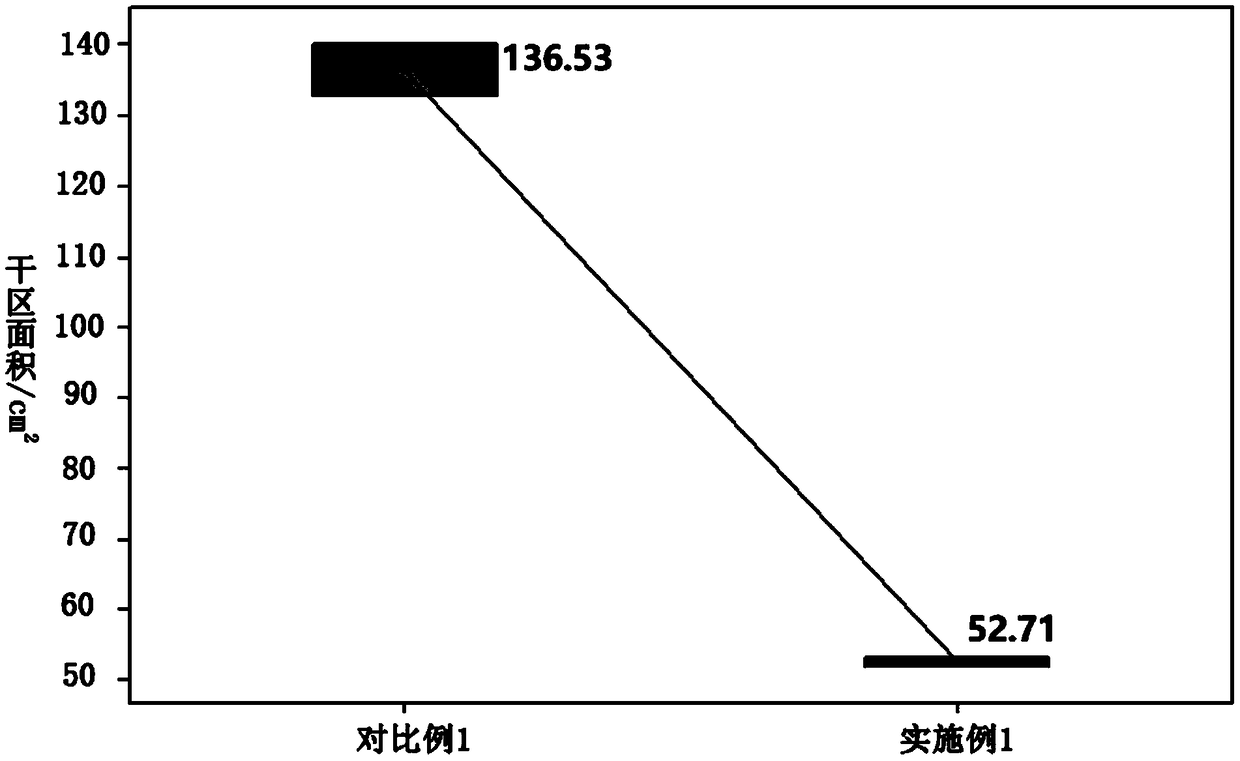

A battery and liquid injection technology, which is applied in the field of energy storage, can solve the problems of long time consumption and achieve the effect of increasing the infiltration rate of liquid injection, shortening the infiltration time, and reducing the area of dry area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This implementation provides a battery liquid injection method, the method includes the following steps:

[0079] (1) Inject the electrolyte solution into the cylindrical 18650 battery to be treated with a liquid injection cup to obtain the injected battery. The injected battery is maintained at -95kPa for 70s, and then vented to normal pressure for 5s, and then - Maintain at 95kPa for 60s, exhaust for 5s to normal pressure, first maintain at 0.35MPa for 185s, exhaust for 10s to normal pressure, then maintain at 0.35MPa for 100s, exhaust for 5s to normal pressure, and get the pretreated battery ;

[0080] Among them, the injection volume of the electrolyte is 25.04% of the volume of the inner cavity of the battery shell to be treated;

[0081] (2) The pretreated battery described in step (1) was left standing at -95kPa for 30s, then exhausted for 5s to normal pressure and left at 0.35MPa for 60s, Complete a differential pressure treatment cycle after exhausting for 5 ...

Embodiment 2

[0093] This implementation provides a battery liquid injection method, the method includes the following steps:

[0094] (1) Inject the electrolyte solution into the cylindrical 18650 battery to be treated with a liquid injection cup to obtain the injected battery. The injected battery is maintained at -100kPa for 60s, and then exhausted for 10s to normal pressure, and then - Maintain at 100kPa for 50s, exhaust for 10s to normal pressure, first maintain at 0.4MPa for 180s, exhaust for 12s to normal pressure, then maintain at 0.4MPa for 90s, exhaust for 10s to normal pressure, and get the pretreated battery ;

[0095] Wherein, the injection amount of the electrolyte is 25.570% of the inner cavity volume of the battery case to be treated;

[0096] (2) The pretreated battery described in step (1) was left standing at -100kPa for 25s, then exhausted for 10s to normal pressure and left at 0.4MPa for 50s, Complete a differential pressure treatment cycle after exhausting for 10s to...

Embodiment 3

[0101] (1) Inject the electrolyte solution into the cylindrical 18650 battery to be treated with a liquid injection cup to obtain the injected battery. The injected battery is maintained at -90kPa for 80s, and then vented to normal pressure for 5s, and then - Maintain at 90kPa for 70s, exhaust for 4s to normal pressure, first maintain at 0.3MPa for 190s, exhaust for 8s to normal pressure, then maintain at 0.3MPa for 110s, exhaust for 4s to normal pressure, and get the pretreated battery ;

[0102] Wherein, the injection amount of the electrolyte is 24.505% of the inner cavity volume of the battery case to be treated;

[0103] (2) The pretreated battery described in step (1) was left standing at -90kPa for 35s, then exhausted for 4s to normal pressure and left at 0.3MPa for 70s, Complete a pressure difference processing cycle after exhausting for 4s to normal pressure;

[0104] (3) Repeat the differential pressure treatment cycle of step (2) for 4 times to obtain a cycled bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com