A method for detecting white dot defect of light guide plate

A defect detection and light guide plate technology, which is applied in image analysis, image enhancement, instruments, etc., can solve the problems of unsatisfactory detection accuracy and detection efficiency of manual visual inspection, sensitive manual methods, and inability to completely eliminate white spots on the light guide plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

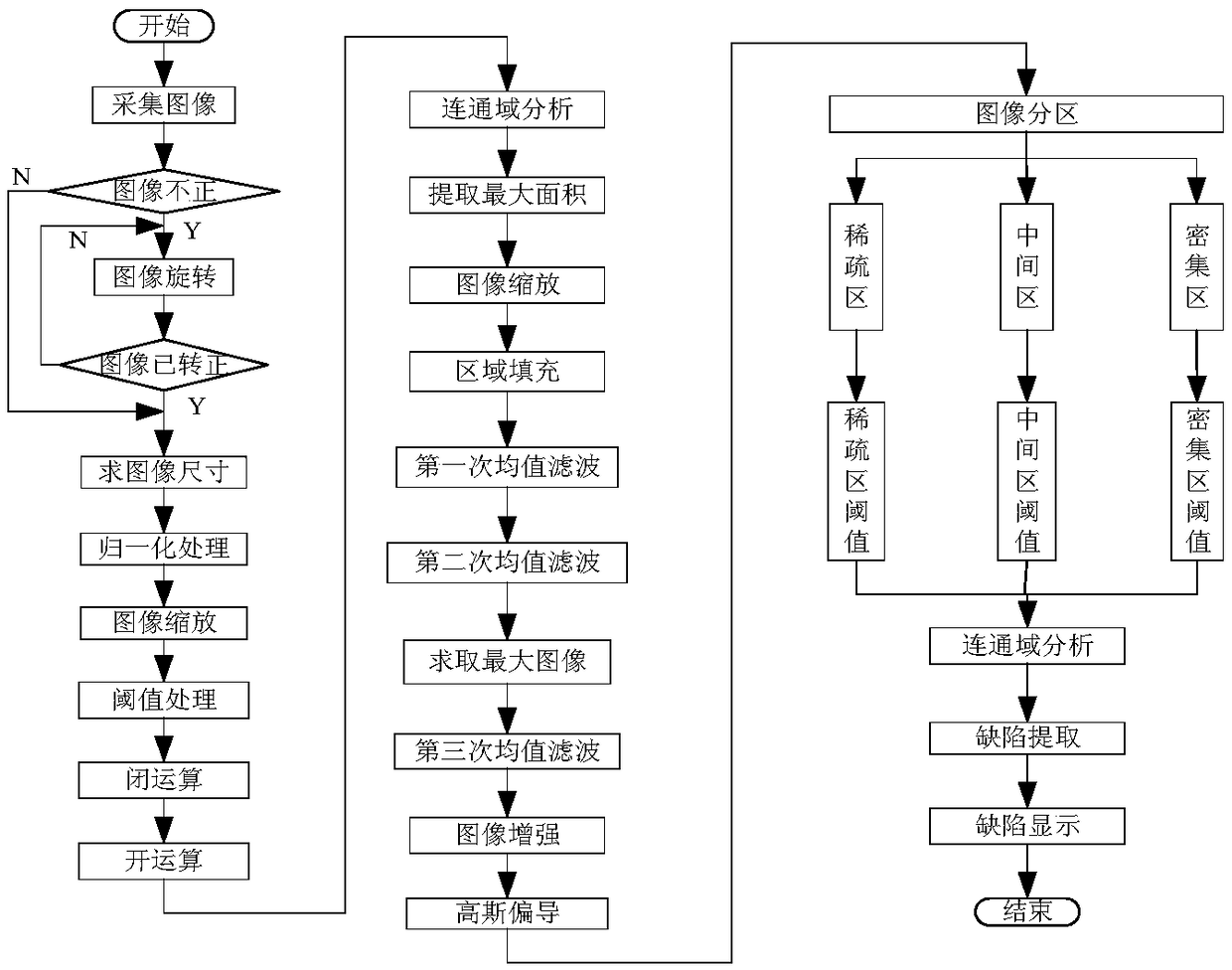

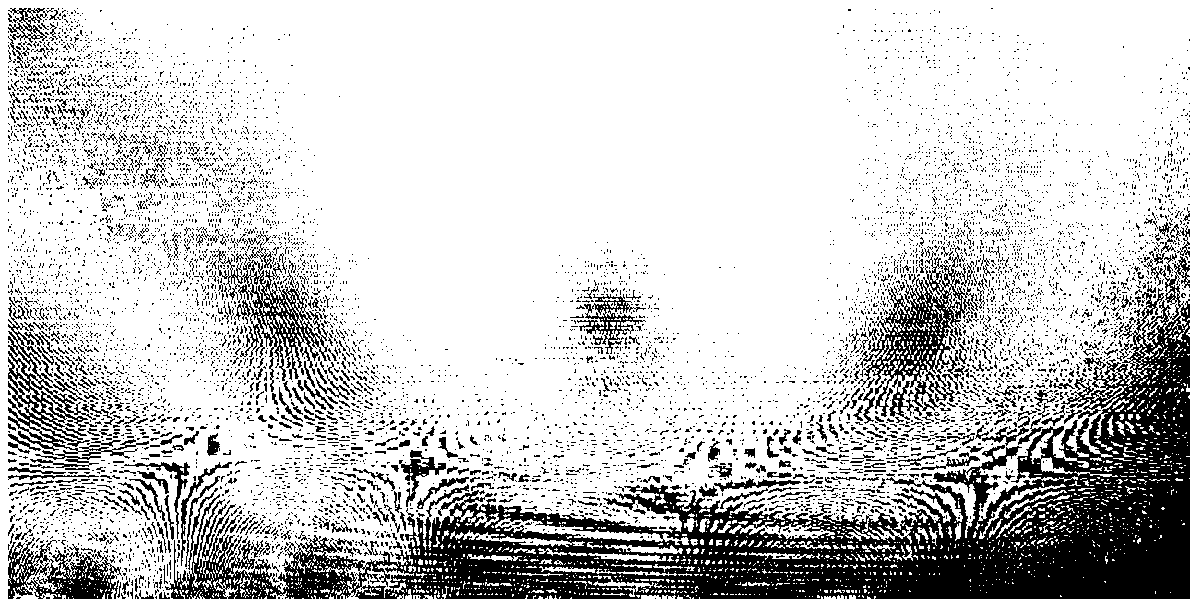

[0099] Embodiment 1, light guide plate white point defect detection method, such as Figure 1-18 shown, including the following steps:

[0100] 1), acquire the image of the light guide plate; perform step 2;

[0101] There are mainly two steps here:

[0102] First, the image acquisition operation of the light guide plate product is carried out through the camera;

[0103] Second, because the image of the light guide plate collected by the camera may be tilted incorrectly, in order to facilitate subsequent operations, the image of the light guide plate needs to be rotated and straightened.

[0104] The specific operation is:

[0105] First, judge whether the collected image is tilted or not (calculate whether the angle between the long side of the light guide plate image and the horizontal direction is zero); if the tilt is not correct (the angle between the long side of the light guide plate image and the horizontal direction is not zero), Then perform image rotation, calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com