Method and device for measuring abrasion of overhead contact system conductor

A measurement method and catenary technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of rigid suspension busbars with no elasticity, large wear degree of contact lines, large impulse, etc. Wide-ranging, easily scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

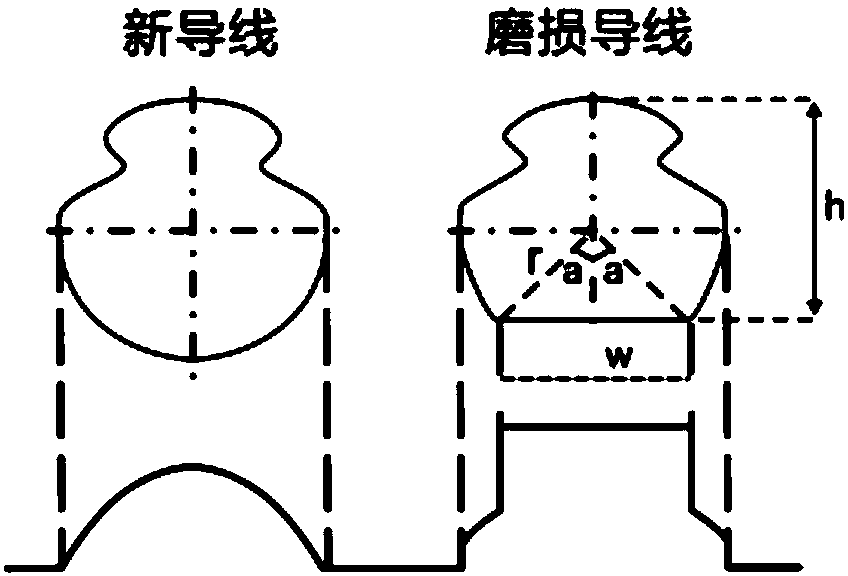

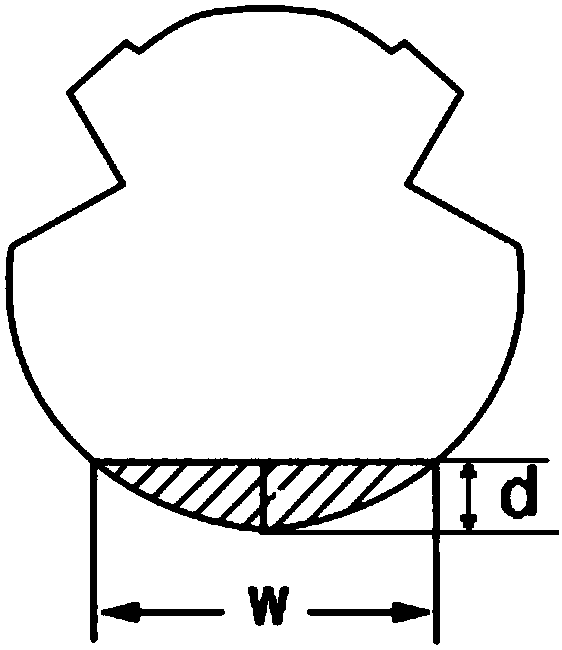

[0058] A catenary wire wear measurement method comprising:

[0059] Step 1 (image collection step): n road cameras correspondingly collect n pieces of catenary wire images including the bottom of the catenary wire located in different pull-out value ranges; n is greater than or equal to 1;

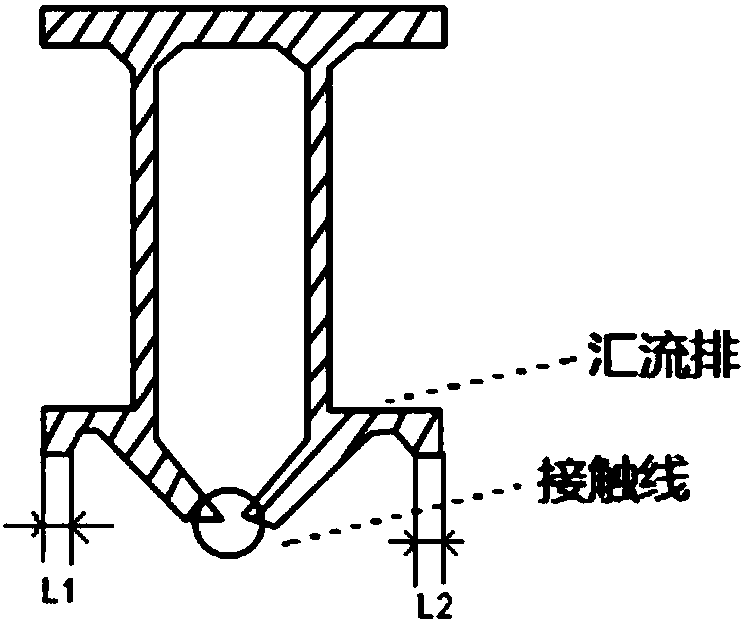

[0060] Among them, when the wear measurement requires detection of the pull-out value range beyond the effective pull-out value range of the single-channel image acquisition camera, the L2 width information cannot be recognized, and the wire wear value d cannot be calculated, and it is judged whether the single image is caused by The L1 line segment, L2 line segment, and L3 line segment do not exist locally; then, n-channel cameras are used to collect the wire images in different pull-out value ranges, and the pull-out value distribution has a certain range of overlapping intervals. Fusion is mainly responsible for merging and correlating the positions of the wires in the images captured b...

Embodiment 2

[0083] Embodiment 2: when the wear value calculation step cannot calculate the wire wear value d, then after the wire positioning step, the wire contour tracking step is also included before the wear value calculation step (then first, the wire position fusion is performed on the n-way camera images to obtain The position information of the wire in different camera images, and then the wire tracking process is performed to compensate for the wire breakage in the image caused by the complexity of the line, and finally after the complete position information of L1, L2 and L3 is obtained by tracking, the wire wear value is identified and calculated) , (this step is suitable for n=1, also suitable for n greater than or equal to 2), specifically:

[0084] Step 51: refine the central positions of L1, L2 and L3;

[0085] Step 52: On the basis of the maximum connected domain of the wires, the center positions of L1, L2, and L3 are combined with the boundary positions E1 and E2 to iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com