A cast microchannel compact heat exchanger and its manufacturing method

A heat exchanger, a compact technology, applied in the field of heat exchange, to achieve high reliability, improve high temperature and high pressure resistance, and avoid thermal fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0059] Heat exchanger structure

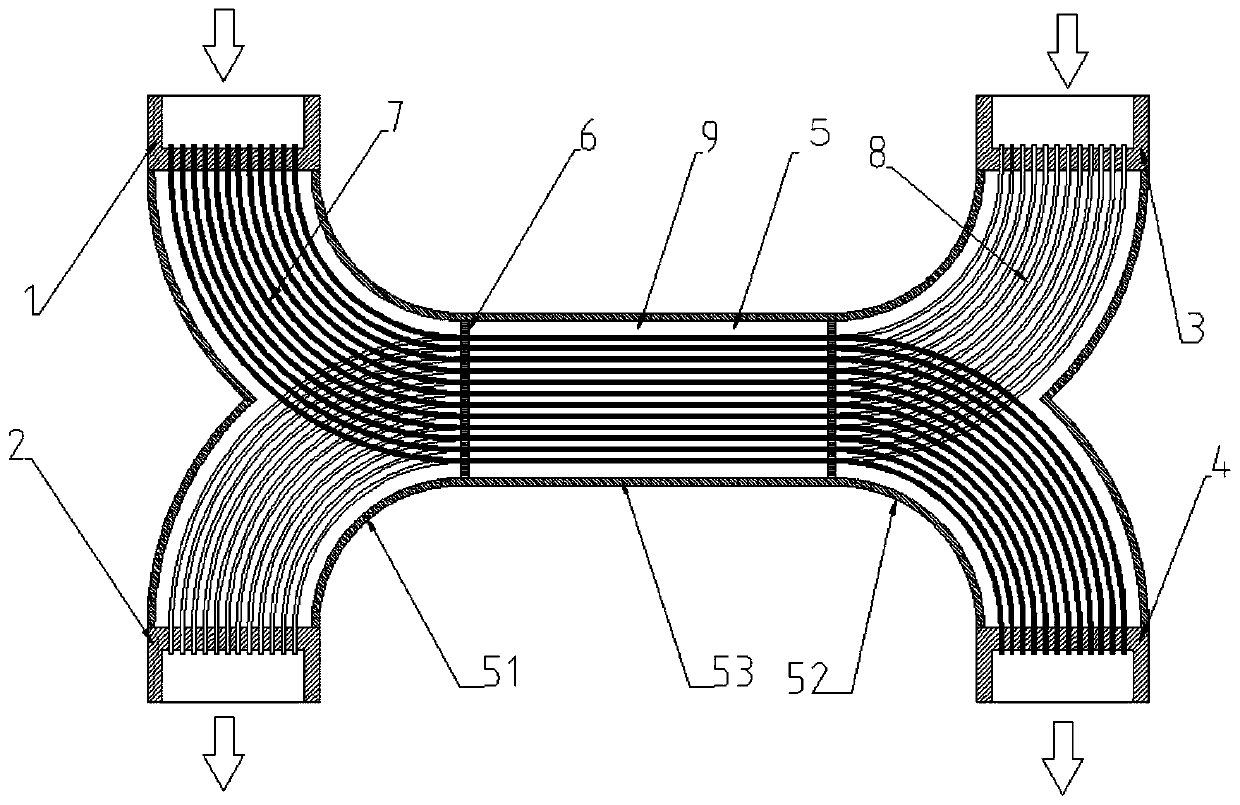

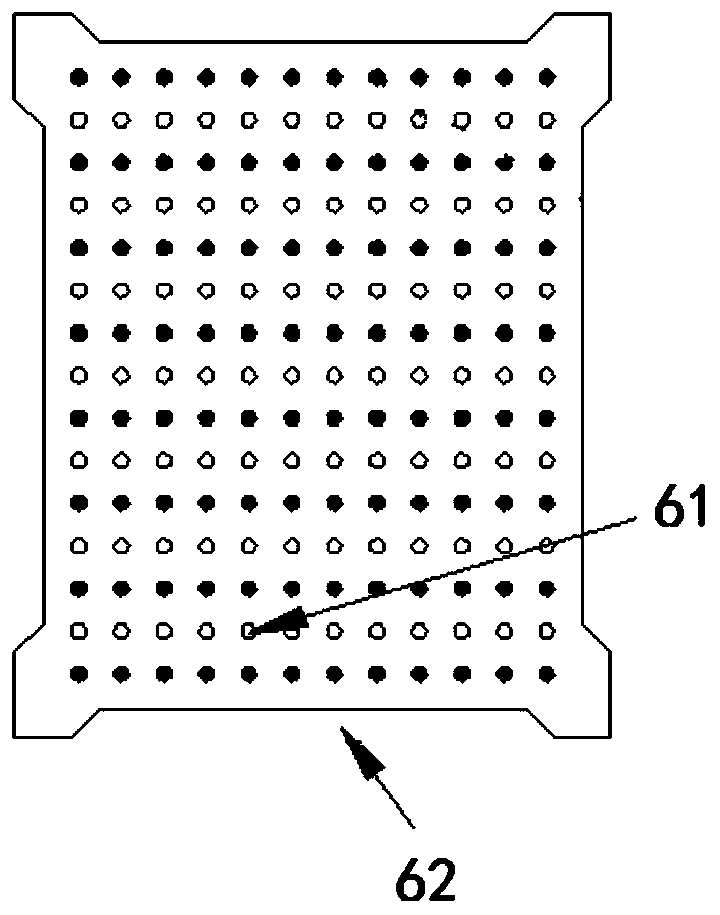

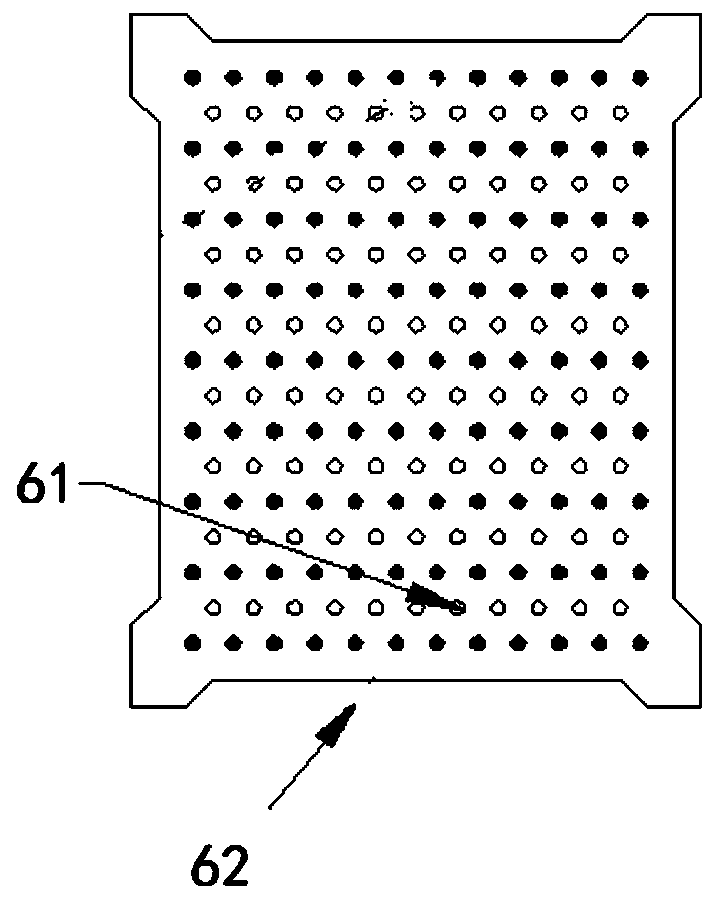

[0060] A cast microchannel compact heat exchanger provided by the present invention includes: a heat exchanger shell 5, a first tube sheet 1, a second tube sheet 2, a third tube sheet 4, a fourth tube sheet 3, a first Composed of a liner 7, a second liner 8, a support tube plate 6, and a heat-conducting core 9;

[0061] Heat exchanger shell 5 is made up of first Y-shaped pipe 51, second Y-shaped pipe 52 and straight pipe 53, and wherein the pipe wall of straight pipe 53 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com