Low-heating-value gas burner and hot blast heater

A gas burner and low calorific value technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of low combustion efficiency, high investment, large size requirements, etc., achieve high combustion efficiency, reduce investment, and wide adjustment range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The embodiment of the present invention provides a low-calorific-value gas burner that uses low-calorific-value gas as fuel and has a large heating capacity. Large and difficult to operate and adjust. The low calorific value gas burner will be described in detail below.

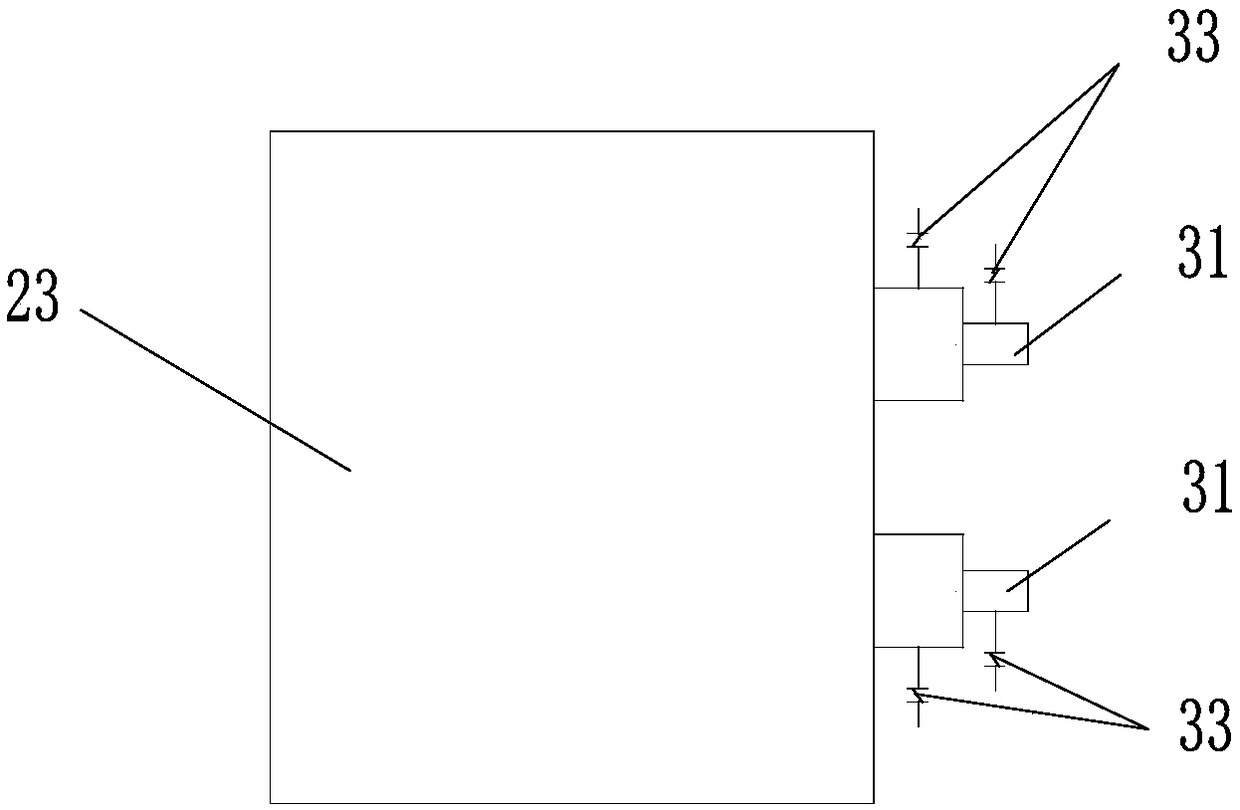

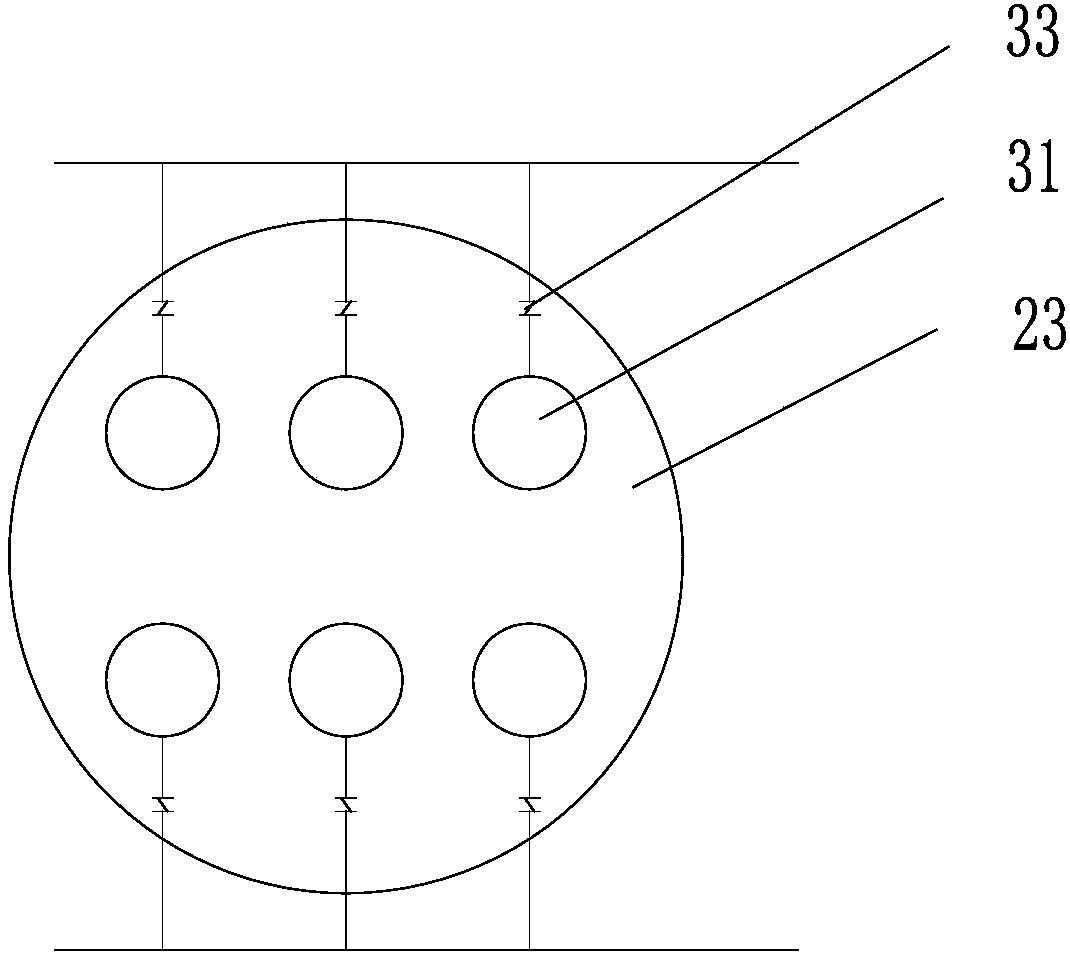

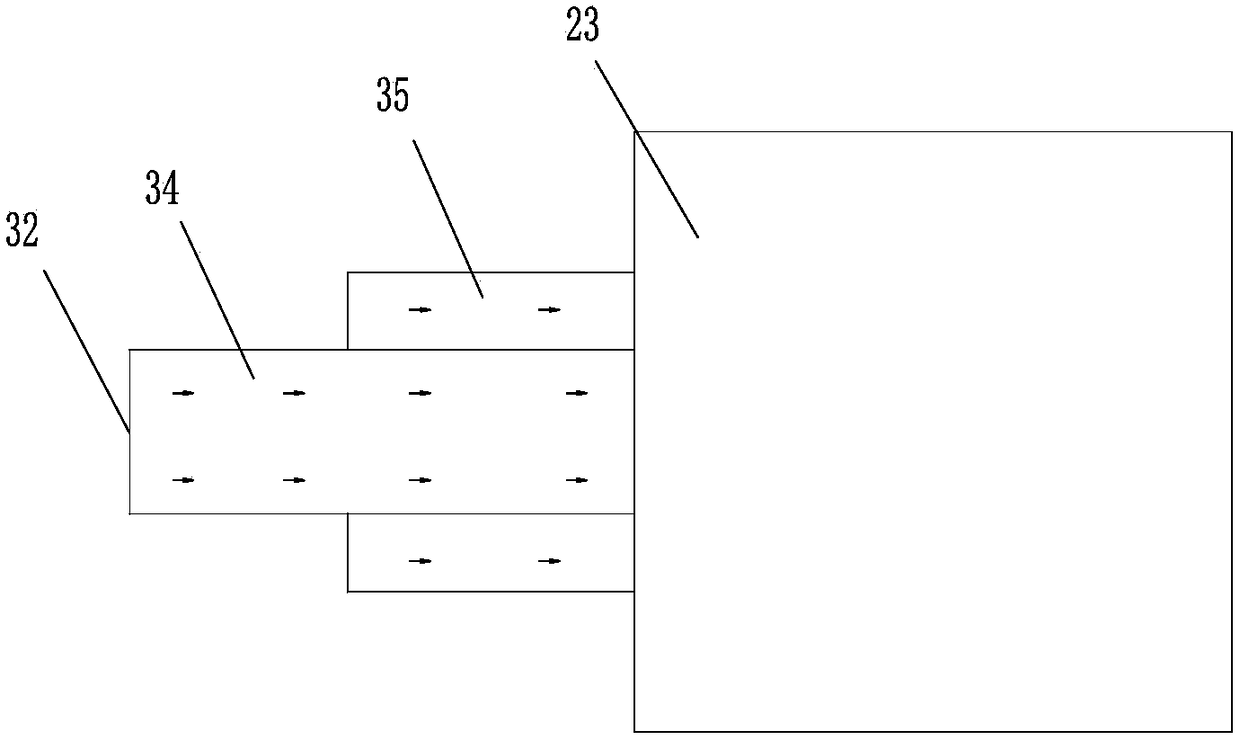

[0038] Such as Figure 5-8As shown, the low calorific value gas burner described in the embodiment of the present invention includes an external main burner and an internal auxiliary burner, wherein the external main burner includes an external distribution pipe 1, a A plurality of first gas pipelines 2 and a plurality of first nozzles 3 connected to the first gas pipelines 2 in one-to-one correspondence, on which first nozzles 3 are installed a first mixing nozzle 4 . The internal auxiliary burner includes an internal distribution pipe 5, a plurality of second gas pipelines 6 arranged in the internal distribution pipe 5, and a plurality of second nozzles 7 connected to the second gas pipelines 6 in ...

Embodiment 2

[0050] The embodiment of the present invention provides a hot blast stove that uses low-calorific-value gas as fuel and has a large heating capacity to solve the problems of large volume, high investment and low heat utilization efficiency when using low-calorific-value gas as fuel in the existing hot-blast stove. The hot blast stove will be described in detail below.

[0051] Such as Figure 9 As shown, on the basis of the first embodiment above, the embodiment of the present invention also provides a hot blast stove, including a hot blast stove body 21 and a burner 22 arranged on the hot blast stove body, wherein the burner 22 is the above-mentioned low calorific value gas burners.

[0052] Wherein, the hot blast stove body includes a combustion chamber 23 and an air mixing chamber 24, and a partition wall 25 is arranged between the combustion chamber 23 and the air mixing chamber 24, and the partition wall 25 is built by interlacing refractory bricks. As a result, the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com