A method for adding a magneto-rheological damper to a tbm support cylinder

A technology of magnetorheological damper and supporting oil cylinder, which is applied in the direction of shock absorber, shock absorber, earth-moving drilling, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and points of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be further described below in conjunction with the drawings in the embodiments of the present invention;

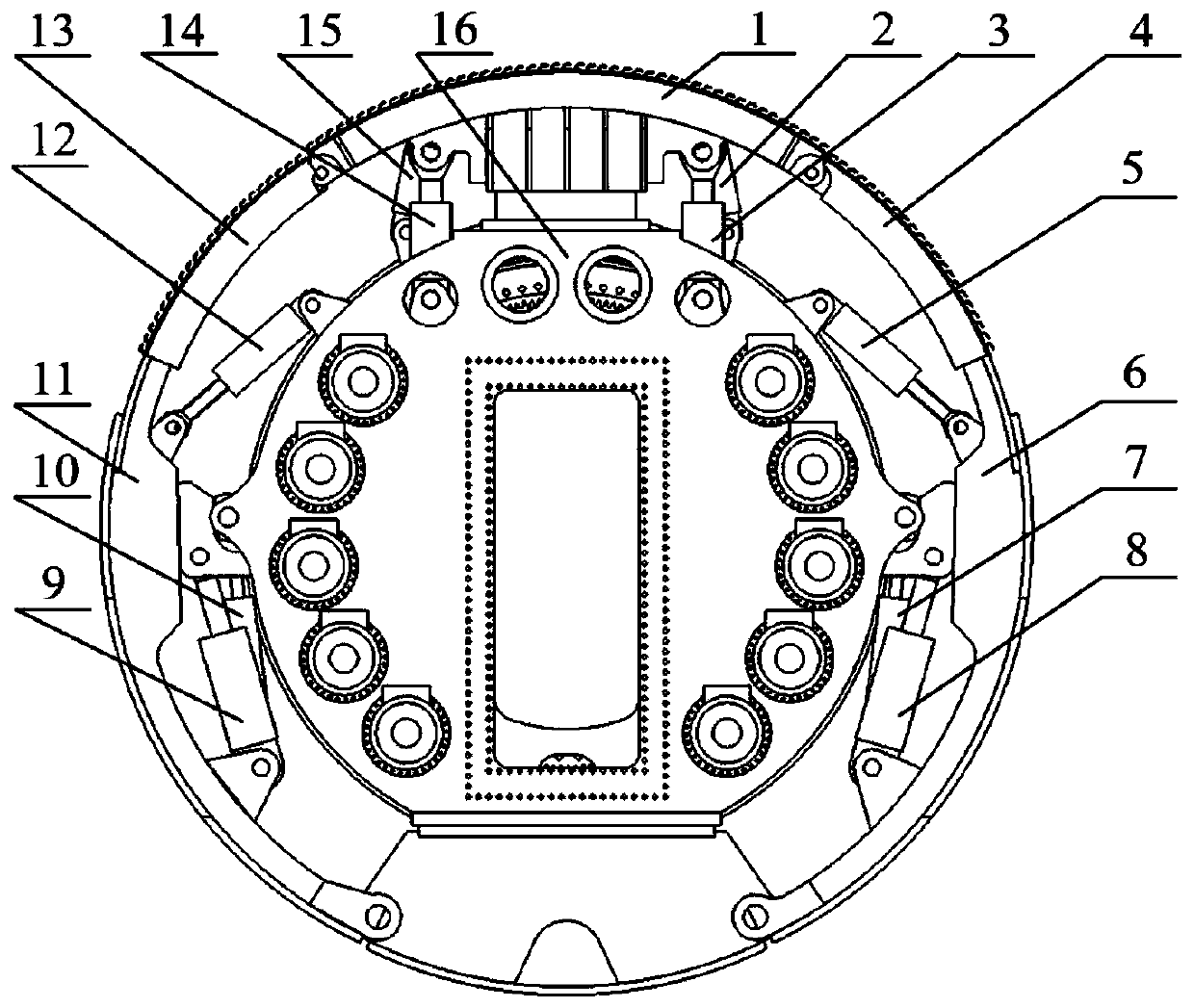

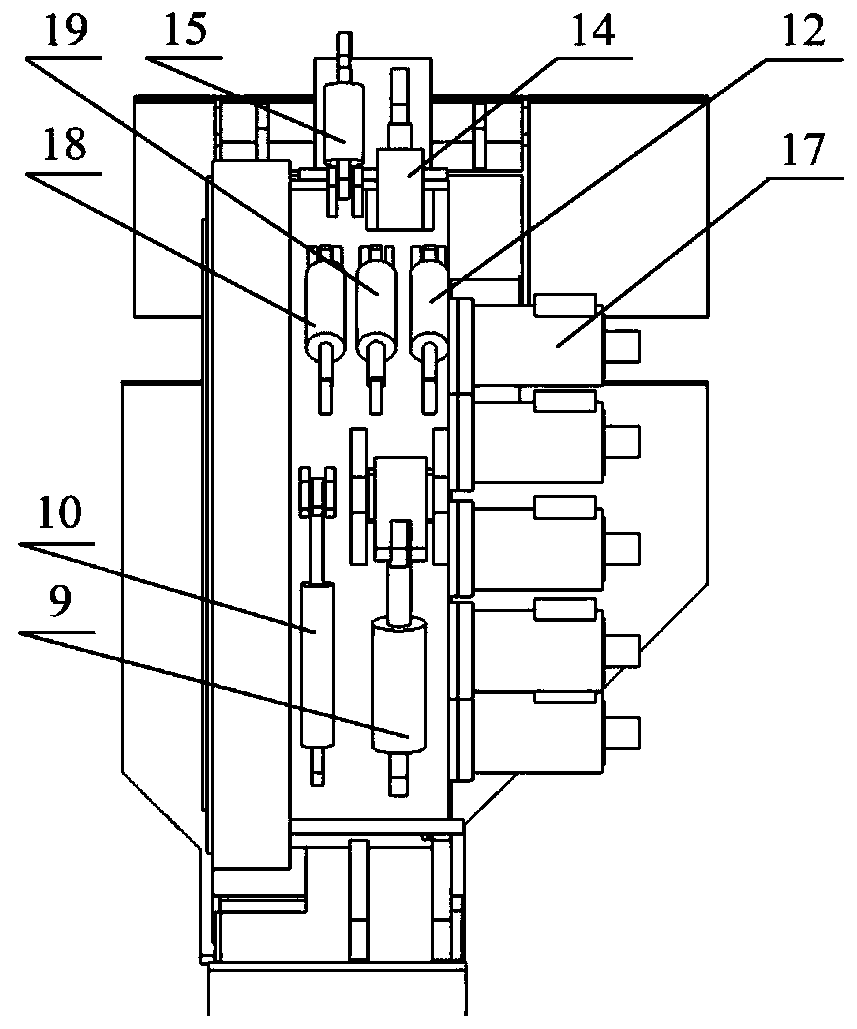

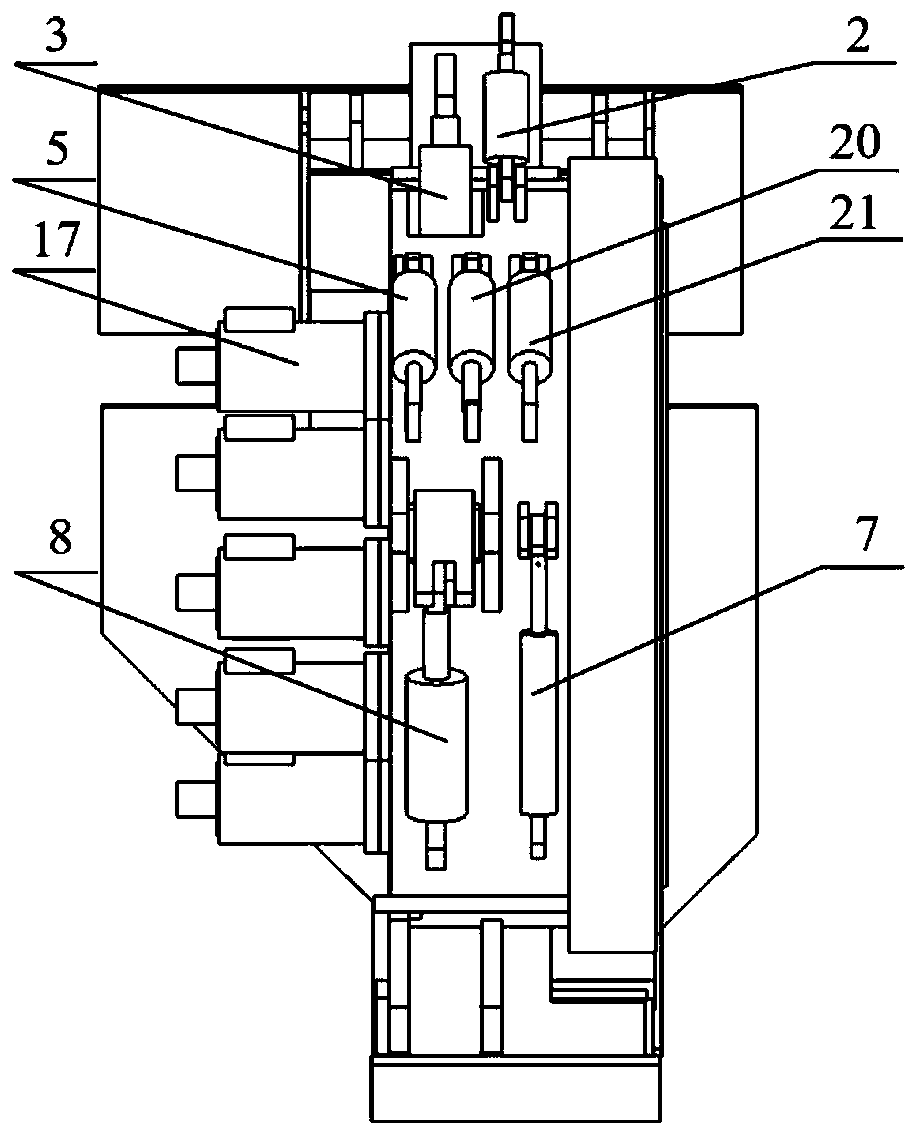

[0018] Such as figure 1 As shown, before the construction starts, when the left top cylinder 14 and the right top cylinder 3 stretch the top shield 1, the left magneto-rheological damper 15 added on the side of the left top cylinder 14 and the right top cylinder Adding the right magnetorheological damper 2 to one side of the oil cylinder 3 also supports the top shield 1 at the same time. During the construction process, by controlling the magnitude of the coil current of the left magnetorheological damper 15 and the right magnetorheological damper 2, Change the viscosity of the magnetorheological fluid 26, and use the generated damping force to absorb the longitudinal vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com