An environment-friendly chemical polishing solution for high-gloss polishing of aluminum and aluminum alloys

A high-gloss, chemical polishing technology, used in the surface treatment industry, can solve the problems of difficult application of automatic lines, corrosion of air passages of parts, and high price, so as to improve residence time and uniformity, reduce COD value, and increase residence time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

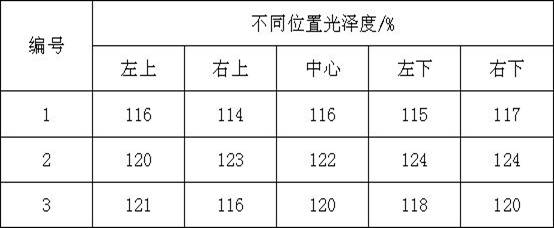

Embodiment 1

[0044] Example 1: An automatic aluminum alloy anodizing line of Shanghai Yinmu Electric Manufacturing Co., Ltd. is mainly engaged in the anodizing and coloring of a 6063 aluminum alloy notebook case. There are many heat dissipation holes and screw holes in the notebook case. The customer requires chemical polishing to be glossy The accuracy is 120±10% (incident angle is 60º), no flow marks visible to the naked eye, no visible airway corrosion in the heat dissipation holes and screw holes, the notebook shell is taken as a test piece for experiments, and the process specification of the chemical polishing solution is obtained for:

[0045]1. Base liquid: 85% concentrated phosphoric acid: 80% (mass fraction), 98% concentrated sulfuric acid: 20% (mass fraction),

[0046] 2. Additive: Sulfolane 75mL / L;

[0047] 3. Temperature: 95°C;

[0048] 4. Time: 150s;

Embodiment 2

[0049] Example 2: An aluminum alloy anodizing automatic line of Shanghai Yinmu Electric Manufacturing Co., Ltd. is mainly engaged in the anodizing and coloring of a 6063 aluminum alloy notebook case. There are many heat dissipation holes and screw holes in the notebook case, and the customer requires chemical polishing. Gloss The accuracy is 120±10% (incident angle is 60º), no flow marks visible to the naked eye, no visible airway corrosion in the heat dissipation holes and screw holes, the notebook shell is taken as a test piece for experiments, and the process specification of the chemical polishing solution is obtained for:

[0050] 1. Base liquid: 85% concentrated phosphoric acid: 90% (mass fraction), 98% concentrated sulfuric acid: 10% (mass fraction),

[0051] 2. Additive: Sulfolane 100mL / L;

[0052] 3. Temperature: 90°C;

[0053] 4. Time: 180s;

Embodiment 3

[0054] Example 3: An aluminum alloy anodizing automatic line of Shanghai Yinmu Electric Manufacturing Co., Ltd. is mainly engaged in the anodizing and coloring of a 6063 aluminum alloy notebook case. The notebook case has many heat dissipation holes and screw holes, and the customer requires chemical polishing. Gloss The accuracy is 120±10% (incident angle is 60º), no flow marks visible to the naked eye, no visible airway corrosion in the heat dissipation holes and screw holes, the notebook shell is taken as a test piece for experiments, and the process specification of the chemical polishing solution is obtained for:

[0055] 1. Base liquid: 85% concentrated phosphoric acid: 85% (mass fraction), 98% concentrated sulfuric acid: 15% (mass fraction),

[0056] 2. Additive: Sulfolane 60mL / L;

[0057] 3. Temperature: 87°C;

[0058] 4. Time: 100s;

[0059] The production line has an acid-resistant and heat-resistant stainless steel chemical polishing tank. The bottom is equipped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com