Anti-UV masking paper adhesive tape

A technology of masking paper and tape, applied in the direction of adhesives, natural rubber adhesives, adhesive types, etc., can solve the problems of good pressure sensitivity, poor anti-UV performance, poor pressure sensitivity, etc., and achieve excellent anti-UV performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

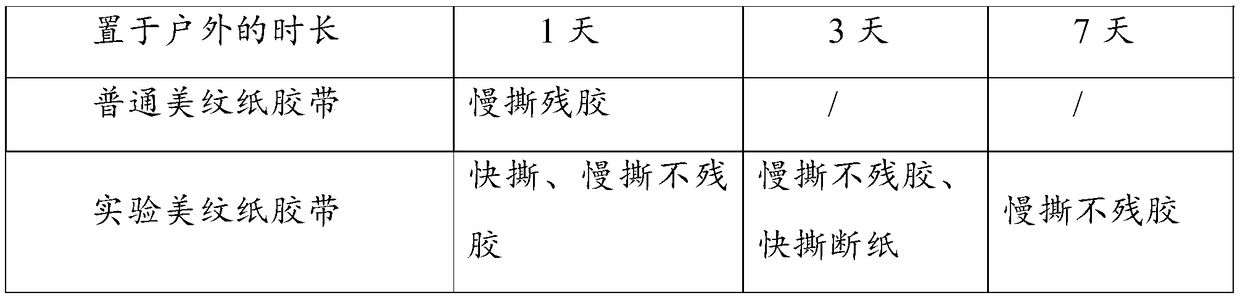

Examples

Embodiment 1

[0029] Preparation of anti-UV adhesive layer 3 glue: Add 15 parts of zinc oxide, 10 parts of calcium carbonate, 100 parts of EPDM, 50 parts of hydrogenated petroleum resin, 2 parts of antioxidant, UV 2 parts of absorbent, stir until completely dissolved and mixed evenly, and the preparation of anti-UV adhesive layer 3 glue is completed;

[0030] Ordinary rubber-based pressure-sensitive adhesive layer 4 glue preparation: Add 15 parts of inorganic filler, 80 parts of ordinary natural rubber, 20 parts of thermoplastic elastomer SIS, 60 parts of petroleum resin, 10 parts of rubber oil, and 2 parts of antioxidant to 300 parts of toluene 2 parts, 2 parts of UV absorbent, stirred until dissolved into a homogeneous phase, that is, the preparation of ordinary rubber-based pressure-sensitive adhesive layer 4 glue is completed;

[0031] Gluing: Use a glue stick to coat the anti-UV glue layer 3 glue layer prepared by the appeal on the masking paper substrate layer 2 with a coating thickne...

Embodiment 2

[0036] Preparation of anti-UV adhesive layer 3 glue: Add 25 parts of calcium carbonate, 100 parts of EPDM, 50 parts of hydrogenated petroleum resin, 2 parts of antioxidant, and 2 parts of UV absorber in 300 parts of toluene, Stir until it is completely dissolved and mixed evenly, and the preparation of the anti-UV adhesive layer 3 glue is completed;

[0037] Ordinary rubber-based pressure-sensitive adhesive layer 4 glue preparation: Add 15 parts of inorganic filler, 80 parts of ordinary natural rubber, 20 parts of thermoplastic elastomer SIS, 60 parts of petroleum resin, 10 parts of rubber oil, and 2 parts of antioxidant to 300 parts of toluene 2 parts, 2 parts of UV absorber, stir until dissolved into a homogeneous phase, and then use an appropriate amount of cross-linking agent (such as isocyanate) to cross-link the glue to further improve the anti-UV effect of the tape, and complete the ordinary rubber-based pressure-sensitive adhesive layer 4 glue the preparation of

[00...

Embodiment 3

[0043] Preparation of anti-UV adhesive layer 3 glue: Add 25 parts of calcium carbonate, 100 parts of EPDM, 50 parts of hydrogenated petroleum resin, 2 parts of antioxidant, and 2 parts of UV absorber to 300 parts of toluene in sequence , stir until completely dissolved and mixed evenly, that is, the preparation of the anti-UV adhesive layer 3 glue is completed;

[0044] Ordinary rubber-based pressure-sensitive adhesive layer 4 glue preparation: Add 15 parts of inorganic filler, 80 parts of ordinary natural rubber, 10 parts of EPDM, 10 parts of thermoplastic elastomer SIS, and 60 parts of petroleum resin to 300 parts of toluene 10 parts, 10 parts of rubber oil, 2 parts of antioxidant, 2 parts of UV absorber, stir until dissolving into a homogeneous phase, that is, complete the preparation of ordinary rubber-based pressure-sensitive adhesive layer 4 glue;

[0045]Gluing: Use a glue stick to coat the anti-UV glue layer 3 glue layer prepared by the appeal on the masking paper subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com