Salt-resistant polyacrylamide for oil displacement and preparation method thereof

A polyacrylamide and acrylamide technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficiency of shearing, polyacrylamide intolerant of temperature, corrosion of pipeline equipment, etc., and achieve product solubility. Improve, improve viscosity retention rate, improve the effect of slow dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

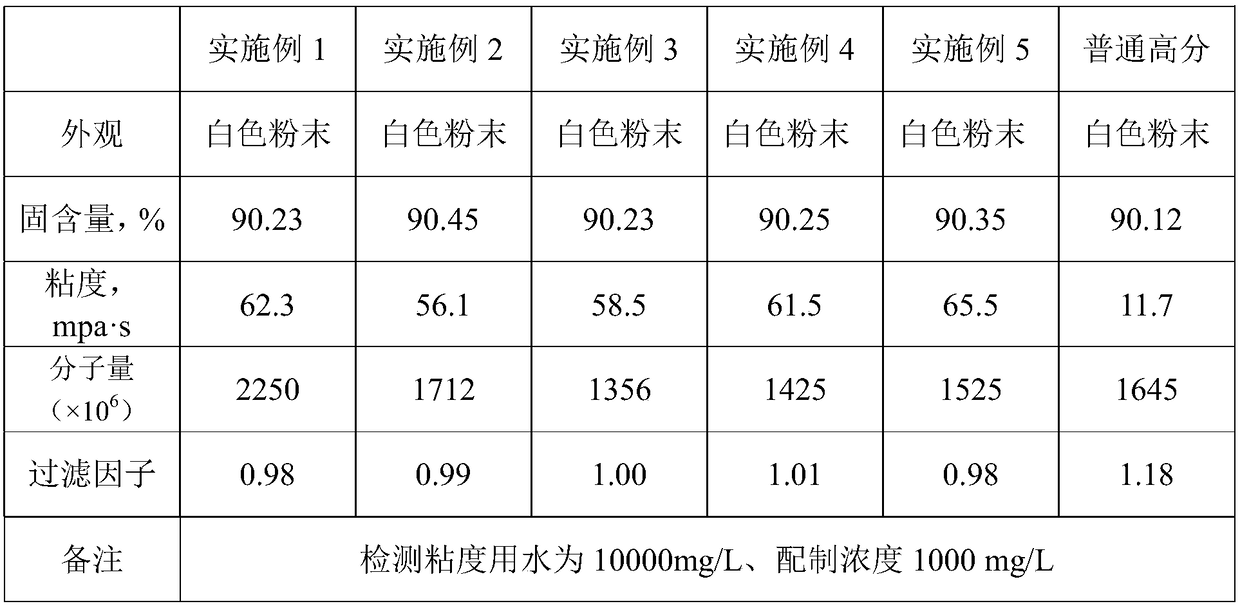

Examples

Embodiment 1

[0028] 1. A salt-resistant polyacrylamide for oil displacement, comprising components and parts by weight: 770 parts of deionized water, 150 parts of acrylamide, 10 parts of 2-acrylamido-2-methylpropanesulfonic acid, functional 5 parts of monomer microemulsion.

[0029] The components and parts by weight of the functional monomer microemulsion are: deionized water: 300 parts, acrylamide: 100 parts, acrylic acid 10 parts, functional monomer with n value of 10 30 parts, 1 part of sodium acetate, 10 parts of sodium hydroxide, 300 parts of white oil, 20 parts of sodium lauryl sulfate.

[0030] Two, a kind of preparation method of salt-resistant polyacrylamide for above-mentioned oil displacement, the steps are as follows:

[0031] Step 1, water phase preparation:

[0032] 300 parts of deionized water, 100 parts of acrylamide, 10 parts of acrylic acid, functional monomer with n value of 10 30 parts, 1 part of sodium acetate, stir evenly, and adjust the pH value to 7 with a mas...

Embodiment 2

[0041] 1. A salt-resistant polyacrylamide for oil displacement, comprising the following components in parts by weight: 840 parts of deionized water, 260 parts of acrylamide, 30 parts of sodium vinyl phosphate, and 40 parts of functional monomer microemulsion.

[0042] The components and parts by weight of the functional monomer microemulsion are: 400 parts of deionized water, 150 parts of acrylamide, 20 parts of acrylic acid, and a functional monomer whose n value is 8 50 parts, 6 parts of anhydrous sodium sulfate, the mass fraction is 10% sodium hydroxide, 500 parts of white oil, 50 parts of fatty alcohol polyoxyethylene ether.

[0043] Two, a kind of preparation method of salt-resistant polyacrylamide for above-mentioned oil displacement, the steps are as follows:

[0044] Step 1, water phase preparation:

[0045] 400 parts of deionized water, 150 parts of acrylamide, 20 parts of acrylic acid, functional monomer with n value of 8 50 parts, 6 parts of anhydrous sodium sul...

Embodiment 3

[0054] 1. A salt-resistant polyacrylamide for oil displacement, comprising the following components in parts by weight: 800 parts of deionized water, 200 parts of acrylamide, 20 parts of vinylpyrrolidone, and 20 parts of functional monomer microemulsion.

[0055] The components and parts by weight of the functional monomer microemulsion are: deionized water: 330 parts, acrylamide: 120 parts, acrylic acid 15 parts, functional monomer with n value of 16 40 parts, 3 parts of sodium acetate, 10% sodium hydroxide by mass fraction, 400 parts of white oil, 35 parts of linear alkylbenzene sulfonate sodium.

[0056] Two, a kind of preparation method of salt-resistant polyacrylamide for above-mentioned oil displacement, the steps are as follows:

[0057] Step 1, water phase preparation:

[0058] 330 parts of deionized water, 120 parts of acrylamide, 15 parts of acrylic acid, functional monomer with n value of 16 40 parts, 3 parts of sodium acetate, stir evenly, and adjust the pH val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com