Method for stabilizing displacing fluid viscosity

A displacement fluid and viscosity technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor high temperature resistance and salt resistance, achieve good viscosity retention effect, reduce usage, and enhance viscosity The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

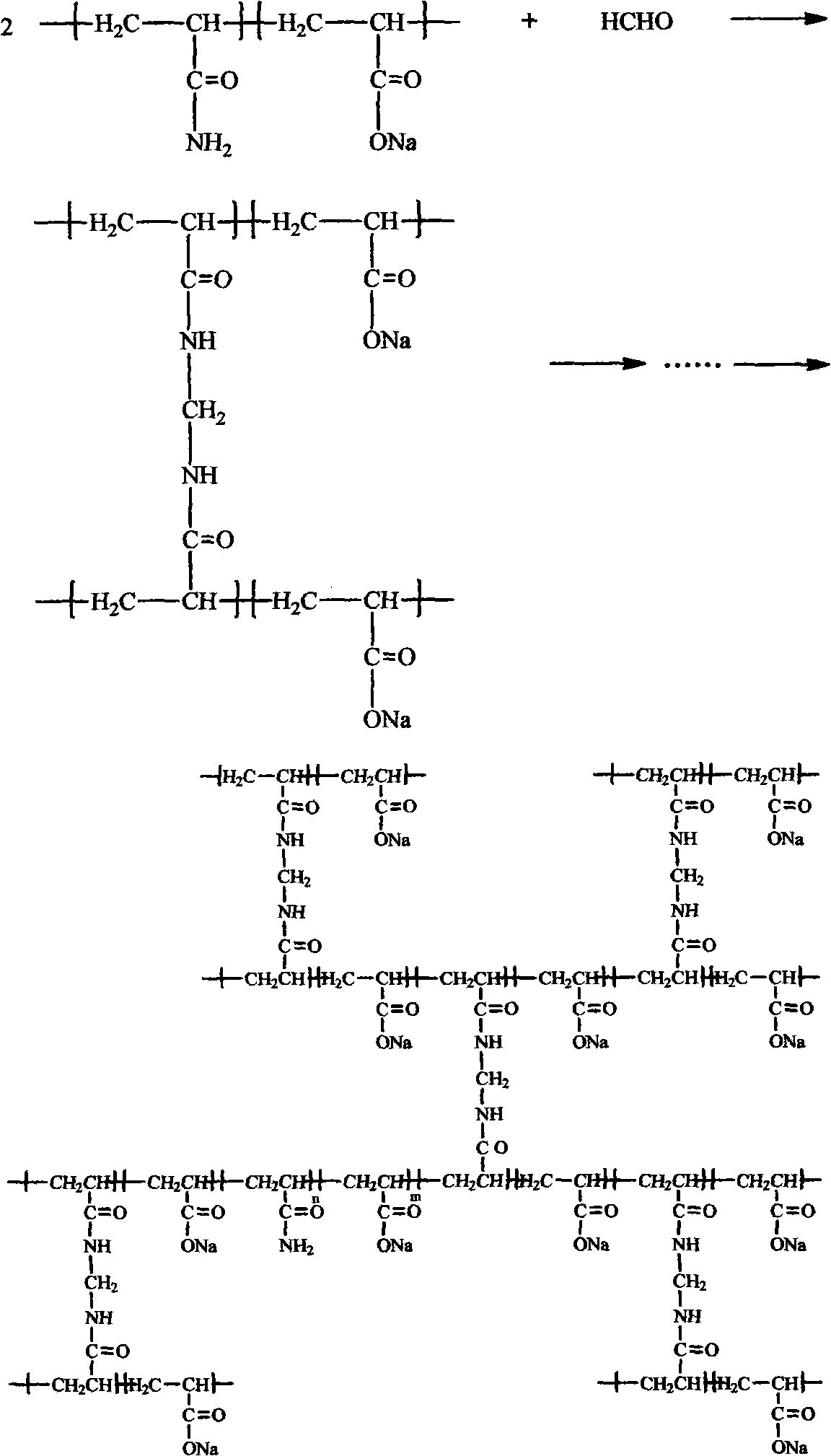

Method used

Image

Examples

Embodiment 1

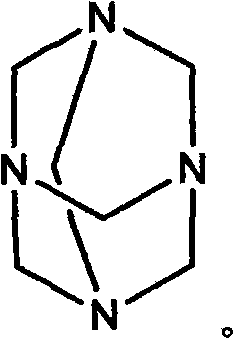

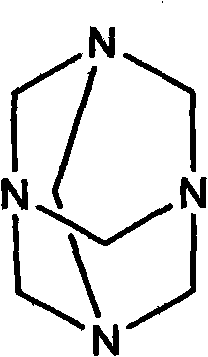

[0035] Molecular weight is 10 million and the degree of hydrolysis is the viscosity retention rate of polyacrylamide solution of 28%. Anionic polyacrylamide with a molecular weight of 10 million and a degree of hydrolysis of 28% and hexamethylenetetramine are selected as the medicament.

[0036] Specific experimental steps:

[0037] Prepare a polyacrylamide mother solution with a concentration of 5000mg / L with water at 2°C, stir for 4 hours, and let stand for 4 hours;

[0038] Use clear water to dilute the mother liquor into a polyacrylamide solution with a concentration of 1500mg / L, stir for 1 hour, and let it stand for 2 hours to make it mix evenly;

[0039] Add hexamethylenetetramine to the prepared solution so that the concentration of hexamethylenetetramine in the solution reaches 15mg / L, stir for 0.5 hours to fully dissolve;

[0040] The prepared samples were stored in a constant temperature water bath at 70°C, and the viscosity changes were regularly measured at 70°C....

Embodiment 2

[0042] Molecular weight is 10 million and the degree of hydrolysis is the viscosity retention rate of polyacrylamide solution of 28%. Anionic polyacrylamide with a molecular weight of 10 million and a degree of hydrolysis of 28% and hexamethylenetetramine are selected as the medicament. Concrete experimental procedure is the same as embodiment 1, but the concentration of hexamethylenetetramine reaches 75mg / L in the solution. See Table 1 for the experimental results.

Embodiment 3

[0044] Molecular weight is 10 million and the degree of hydrolysis is the viscosity retention rate of polyacrylamide solution of 28%. Anionic polyacrylamide with a molecular weight of 10 million and a degree of hydrolysis of 28% and hexamethylenetetramine are selected as the medicament. The specific experimental procedure is the same as in Example 1, but the concentration of hexamethylenetetramine in the solution reaches 150mg / L. See Table 1 for the experimental results.

[0045] Table 1

[0046] Hexamethylenetetramine concentration

[0047] Viscosity after 3 weeks

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com