Multifunctional garbage can

A trash can and multi-functional technology, applied in the field of trash cans, can solve the problems of no protection device, coordination failure, hidden dangers, etc., and achieve the effects of improving use safety, low production cost, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

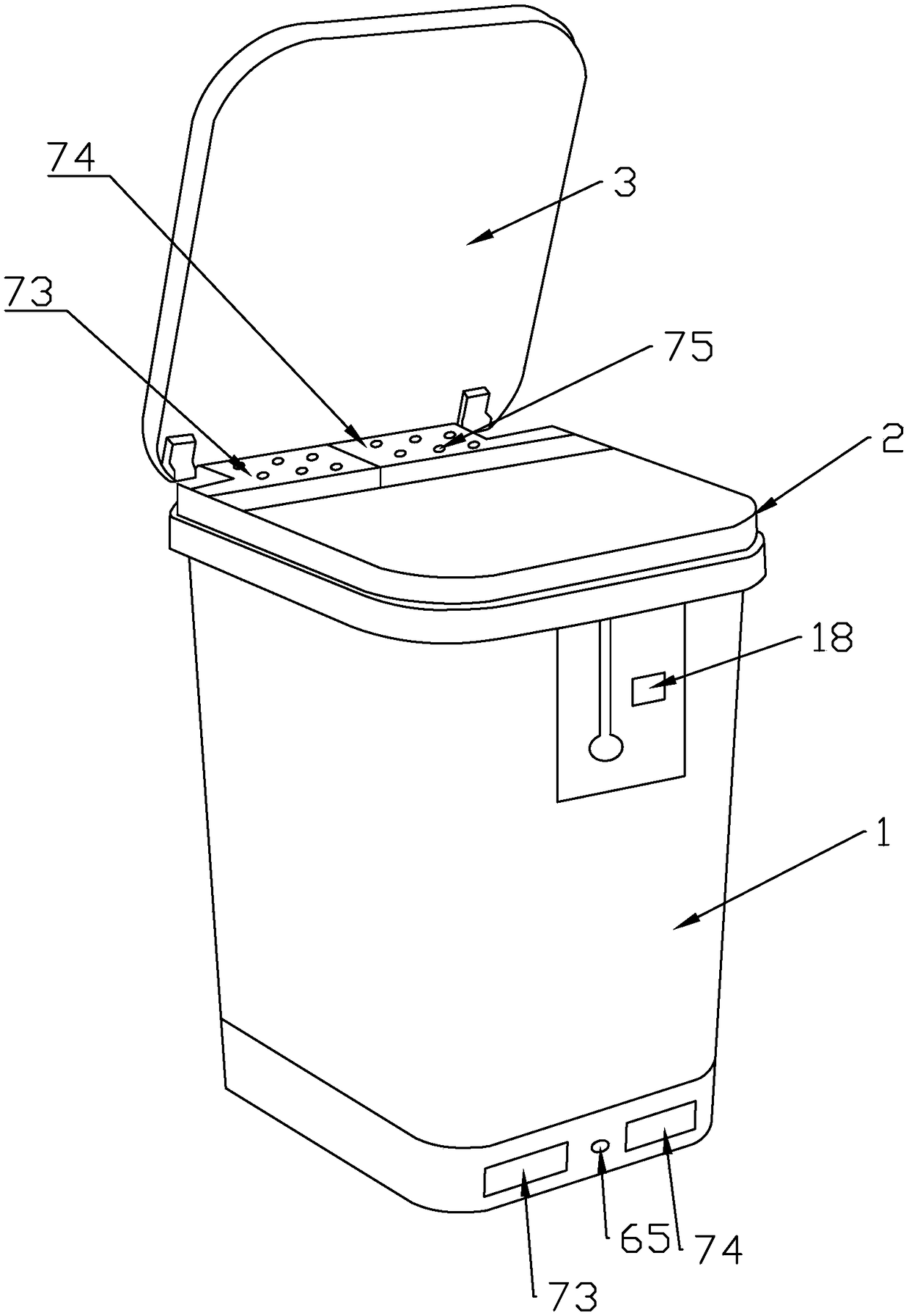

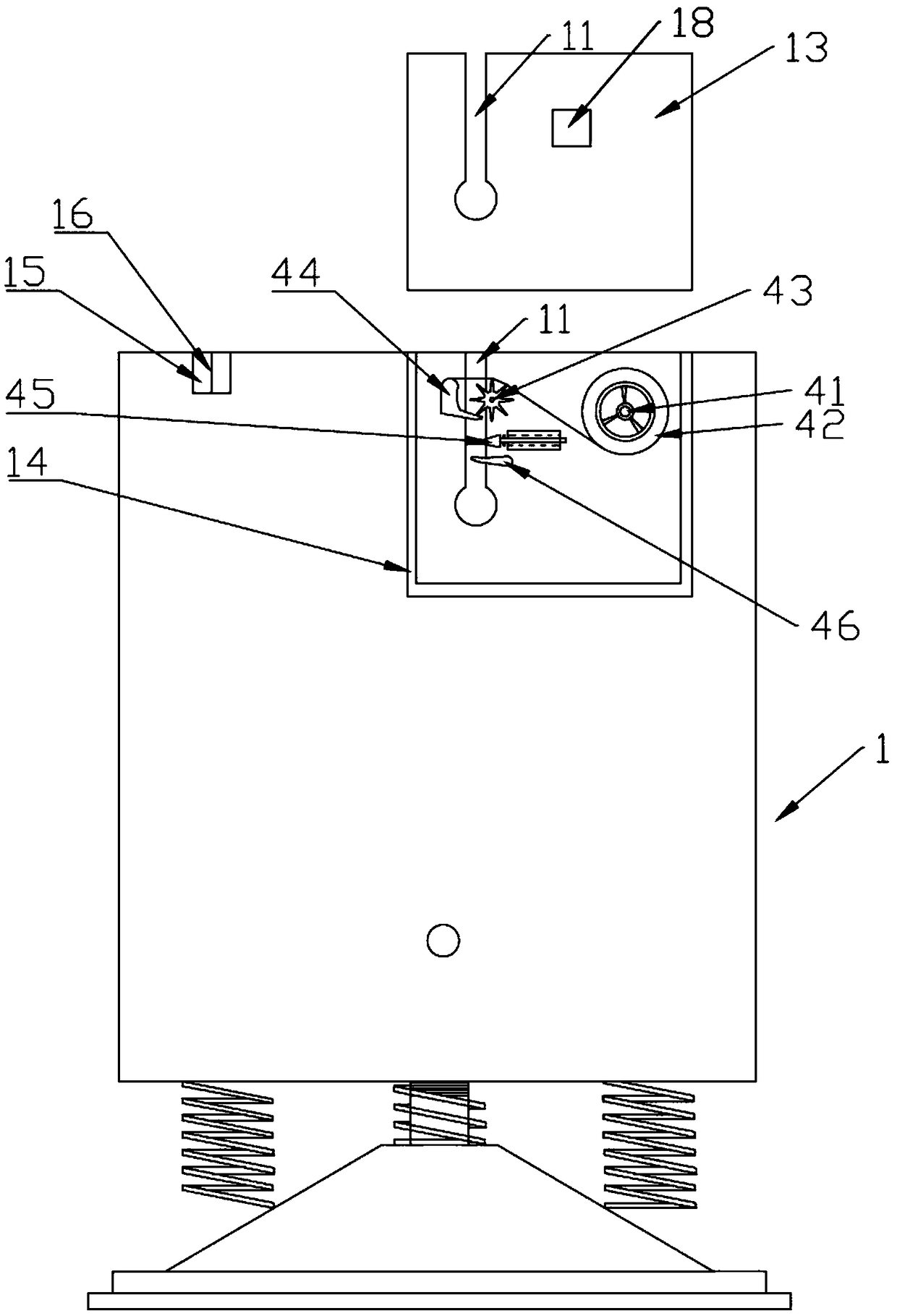

[0040] Such as Figure 1~3 , shown in 6~7, a kind of multi-functional dustbin of the present invention comprises barrel body 1, fixed collar 2 and the bung 3 that is hinged on the fixed collar 2; Open the opening groove 11 that communicates with the opening of the upper end of the barrel body 1 on the front side wall of the barrel body 1, and the opening groove 11 runs through the side wall of the barrel body 1; the upper end of the opening groove 11 is rectangular, the lower end is circular, and the diameter of the circle is The size is larger than the short side of the rectangle; the fixed collar 2 is in the shape of a ring with an opening in the middle, and the lower end of the fixed collar 2 is provided with a card slot, so that the fixed collar 2 is sleeved on the opening end of the barrel body 1 through the card slot; the front of the barrel body 1 The side wall is also provided with a clamping groove 15 communicating with the upper opening of the barrel body 1 , and a c...

Embodiment 2

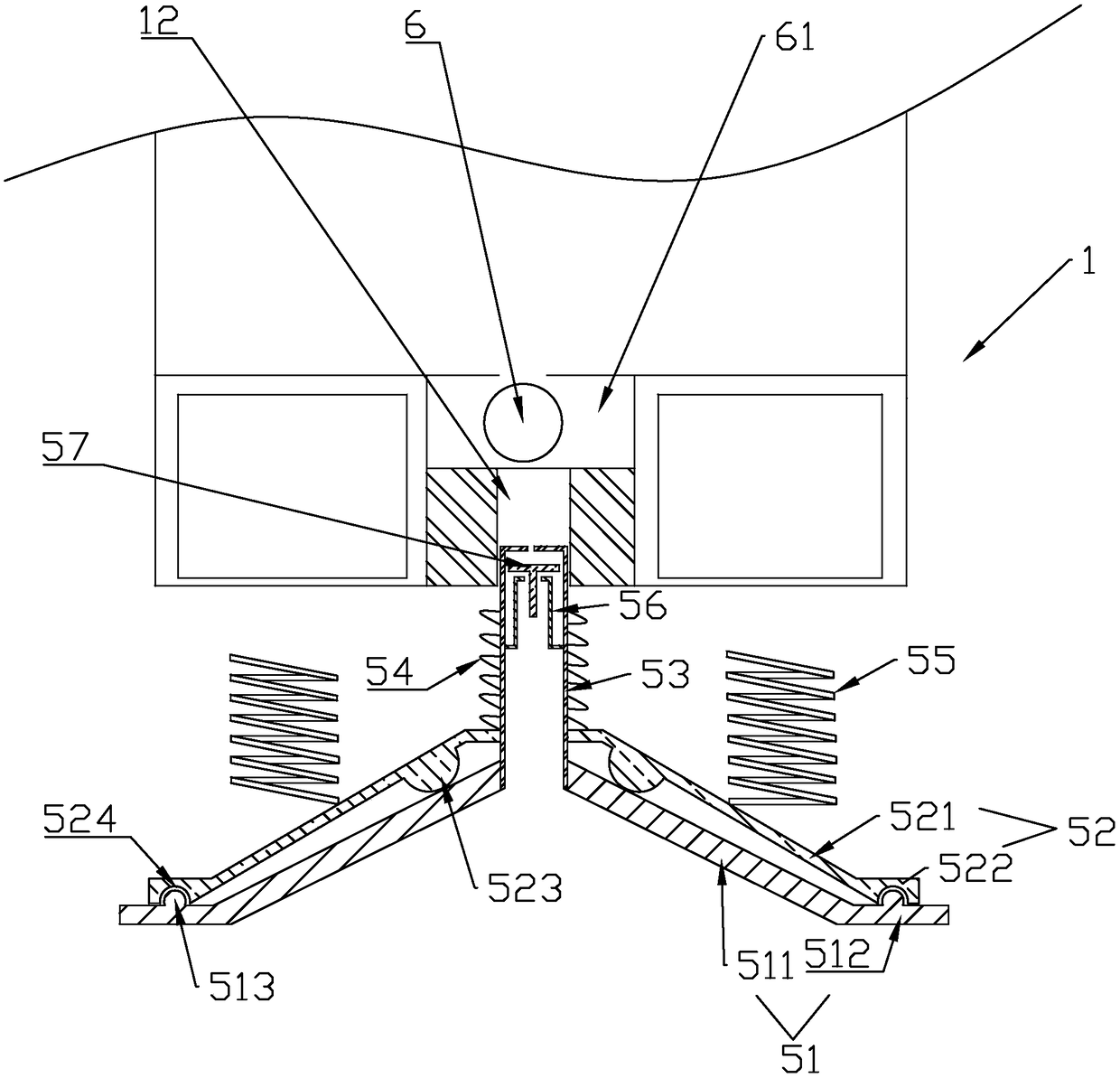

[0047] Such as Figure 1~5 As shown, this embodiment adds a device for placing garbage bag rolls 6 on the basis of Embodiment 1, specifically, the inner side of the bottom of the barrel body 1 is also provided with a first groove 61 for placing garbage bag rolls 6 , the opening of the first groove 61 faces upwards, the first groove 61 is provided with a first cover plate 62, and the first cover plate 62 is clamped at the opening end of the first groove 61. The clamping method is the prior art, such as Specifically, a locking platform is provided on the outer wall of the first groove 61 , and a corresponding locking platform is provided on the inner wall of the first cover plate 62 , so that the first cover plate 62 is locked on the first groove 61 . An opening 63 is opened on the first cover 62 , so that a single garbage bag can be taken out from the opening 63 . Elastic pieces 64 and push rods 65 respectively positioned at both ends of the garbage bag roll 6 are also provide...

Embodiment 3

[0050] Such as Figure 3-4 As shown in and 10, this embodiment adds a pressure plate 52 on the basis of embodiment 2. Specifically, the adsorption device also includes a pressure plate 52 sleeved on the connecting column 53, and the pressure plate 52 is located between the suction cup 51 and the first Between the springs 54, the second spring 55 is arranged on the upper surface of the pressure plate 52; the suction plate 51 includes a lower pressure portion 511 and a contact portion 512, and the pressure plate 52 includes a shell body 521 and an annular portion 522 located at the lower edge of the shell body 521, the shell body The shape of the pressing part 521 is the same as that of the pressing part 511 , and the ring part 522 abuts against the upper surface of the contact part 512 . The annular portion 522 abuts against the upper surface of the contact portion 512 to ensure that the lower surface of the suction cup is in contact with the ground, thereby improving the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com