Freshness protection bag special for fruit refrigeration

A fresh-keeping bag and fruit technology, which is applied in the field of packaging bags, can solve the problems of easy breeding of bacteria, shorten the fresh-keeping period of fruits, and adhere to the inner wall of the fresh-keeping bag, and achieve the effects of preventing the refrigerator temperature from being too low, inhibiting the growth of bacteria, and excellent moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

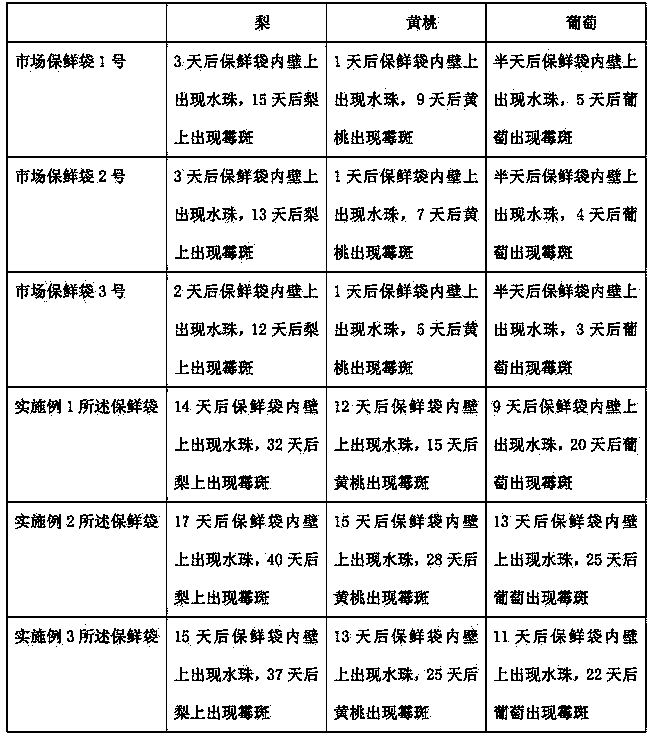

Examples

Embodiment 1

[0023] The fresh-keeping bag specially used for fruit cold storage described in this embodiment includes the following combinations by weight: 35 parts of polyethylene, 5 parts of light calcium carbonate, 3 parts of epoxy soybean oil, 2 parts of gum arabic, and 21 parts of polypropylene , 15 parts of bamboo charcoal fiber, 19 parts of chitosan, 10 parts of sodium polyacrylate, 5 parts of zeolite powder, 2 parts of chloromethoxy fatty acid methyl ester.

[0024] The preparation method of the fresh-keeping bag specially used for fruit refrigeration comprises the following steps:

[0025] (1) After stirring and mixing polyethylene, light calcium carbonate, and epoxy soybean oil for 30 minutes, add gum arabic and stir and mix for 20 minutes, and then directly blow the film into shape, and the temperature of the blown film is controlled at 190°C to obtain an insulating layer;

[0026] (2) the bamboo charcoal fiber is pulverized for subsequent use;

[0027] (3) After polypropylene,...

Embodiment 2

[0031] The fresh-keeping bag specially used for fruit refrigeration described in this embodiment includes the following combinations by weight: 38 parts of polyethylene, 6 parts of light calcium carbonate, 4 parts of epoxy soybean oil, 3 parts of gum arabic, and 23 parts of polypropylene , 16 parts of bamboo charcoal fiber, 21 parts of chitosan, 11 parts of sodium polyacrylate, 7 parts of zeolite powder, 3 parts of chloromethoxy fatty acid methyl ester.

[0032] The preparation method of the fresh-keeping bag specially used for fruit refrigeration comprises the following steps:

[0033] (1) Stir and mix polyethylene, light calcium carbonate, and epoxy soybean oil for 45 minutes, add gum arabic, stir and mix for 25 minutes, and then directly blow the film into shape. The temperature of the blown film is controlled at 200 ° C to obtain an insulating layer;

[0034] (2) the bamboo charcoal fiber is pulverized for subsequent use;

[0035] (3) After polypropylene, zeolite powder, ...

Embodiment 3

[0039] The fresh-keeping bag specially used for fruit cold storage described in this embodiment includes the following combinations by weight: 41 parts of polyethylene, 7 parts of light calcium carbonate, 5 parts of epoxy soybean oil, 4 parts of gum arabic, and 25 parts of polypropylene , 17 parts of bamboo charcoal fiber, 23 parts of chitosan, 12 parts of sodium polyacrylate, 9 parts of zeolite powder, 4 parts of chloromethoxy fatty acid methyl ester.

[0040] The preparation method of the fresh-keeping bag specially used for fruit refrigeration comprises the following steps:

[0041] (1) After stirring and mixing polyethylene, light calcium carbonate, and epoxy soybean oil for 60 minutes, add gum arabic and stir and mix for 30 minutes, and then directly blow the film into shape, and the temperature of the blown film is controlled at 210 ° C to obtain an insulating layer;

[0042] (2) the bamboo charcoal fiber is pulverized for subsequent use;

[0043] (3) After polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com