Double-layer blister forming integrated machine and one-time molding method for double-layer plate

A technology of blister molding and integrated machine, which is applied in the field of one-time molding of double-layer board parts and double-layer blister molding integrated machine field, can solve the problems of large equipment area and long molding cycle of double-layer plastic board parts, and achieve production The effect of high efficiency, shortening molding cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

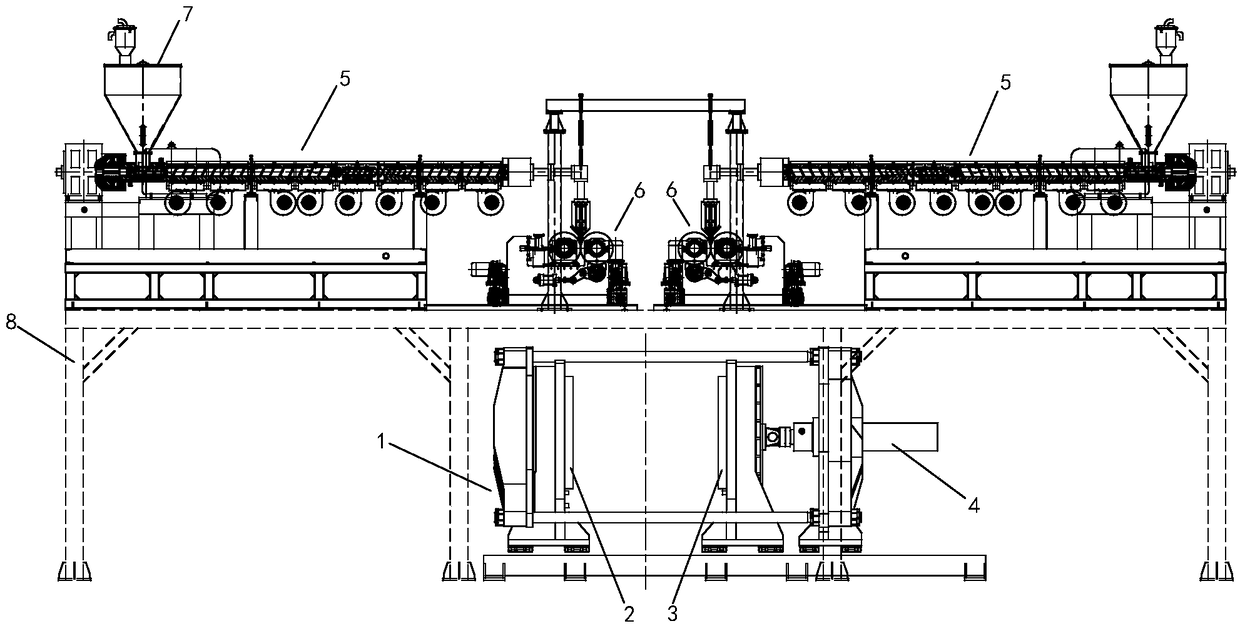

[0035] Please refer to figure 1 , The double-layer blister molding machine includes: a blister molding mold 1, two extruders 5, and two roller groups 6.

[0036] The plastic forming mold 1 has a left mold 2 and a right mold 3, the left mold 2 and the right mold 3 are provided with a first temperature control device (not shown), the first temperature control device includes a heating element and a temperature sensor, The temperature of the left mold 2 and the right mold 3 is controlled by the first temperature control device to realize hot-press fusion of the left and right strips. The plastic forming mold 1 is provided with a first driving mechanism 4 to drive the left mold 2 and the right mold 3 to open and close. The first driving mechanism 4 can adopt a hydraulic device, a pneumatic device or a linear motor or the like.

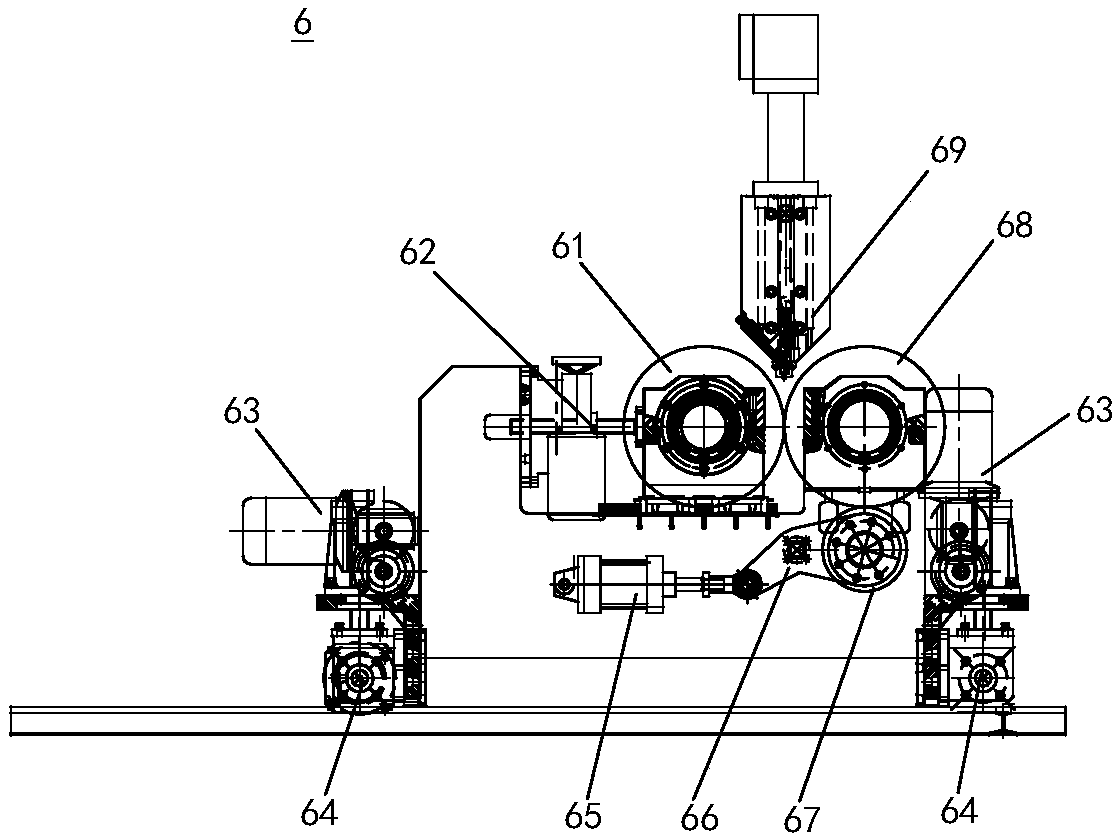

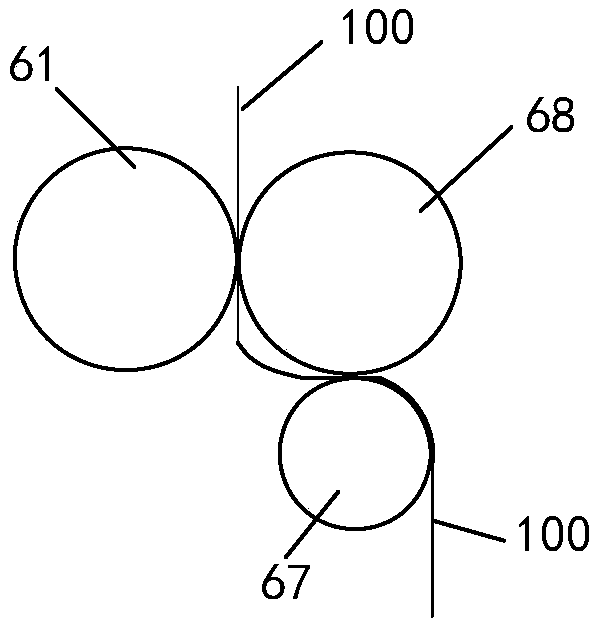

[0037] Two extruders 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com