Chain plate type flexible finger

A flexible finger and chain plate type technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of the scope of application and the suitable grasping force, etc., and achieve the effect of good flexibility, self-adaptability, large gain, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

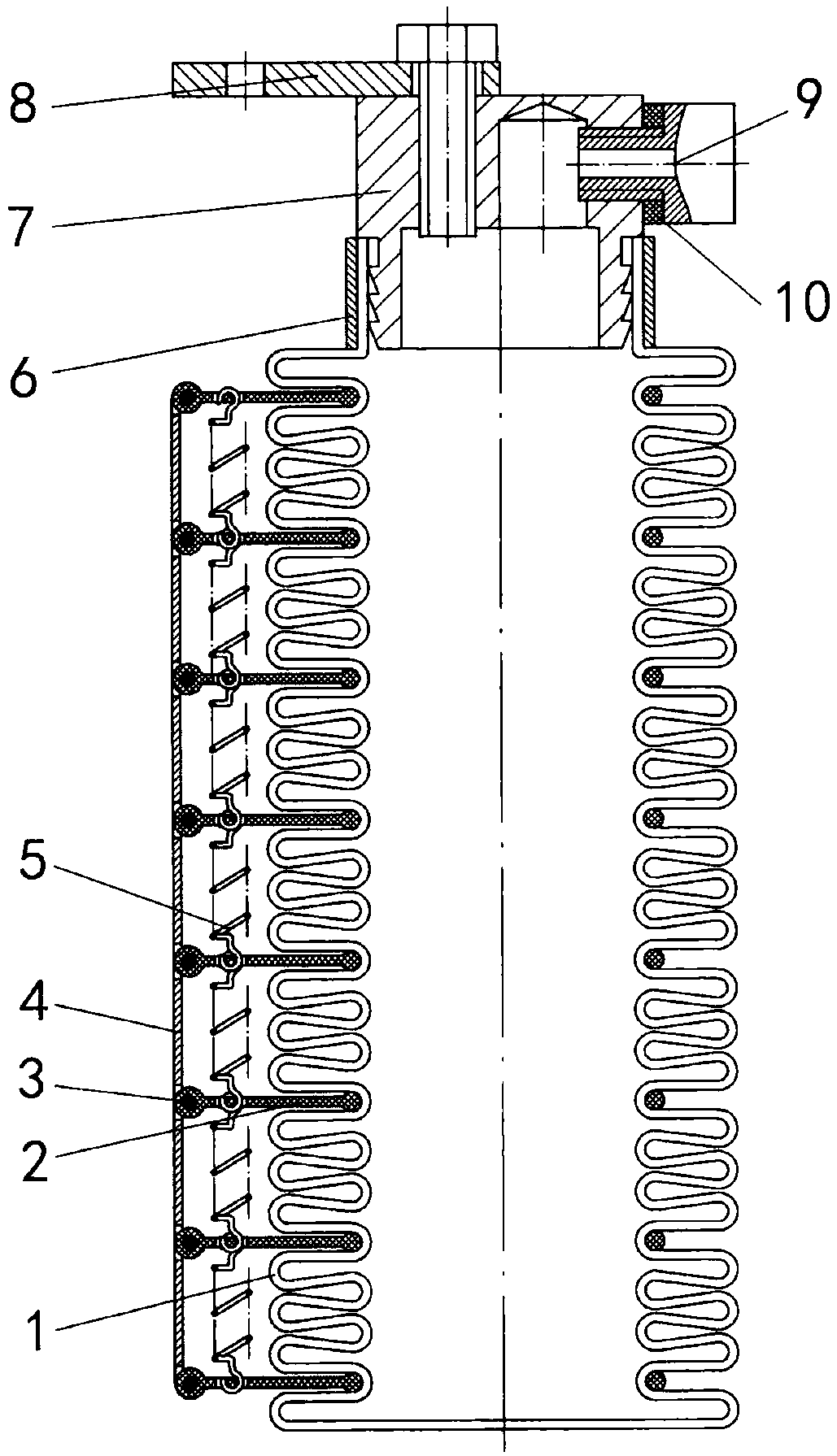

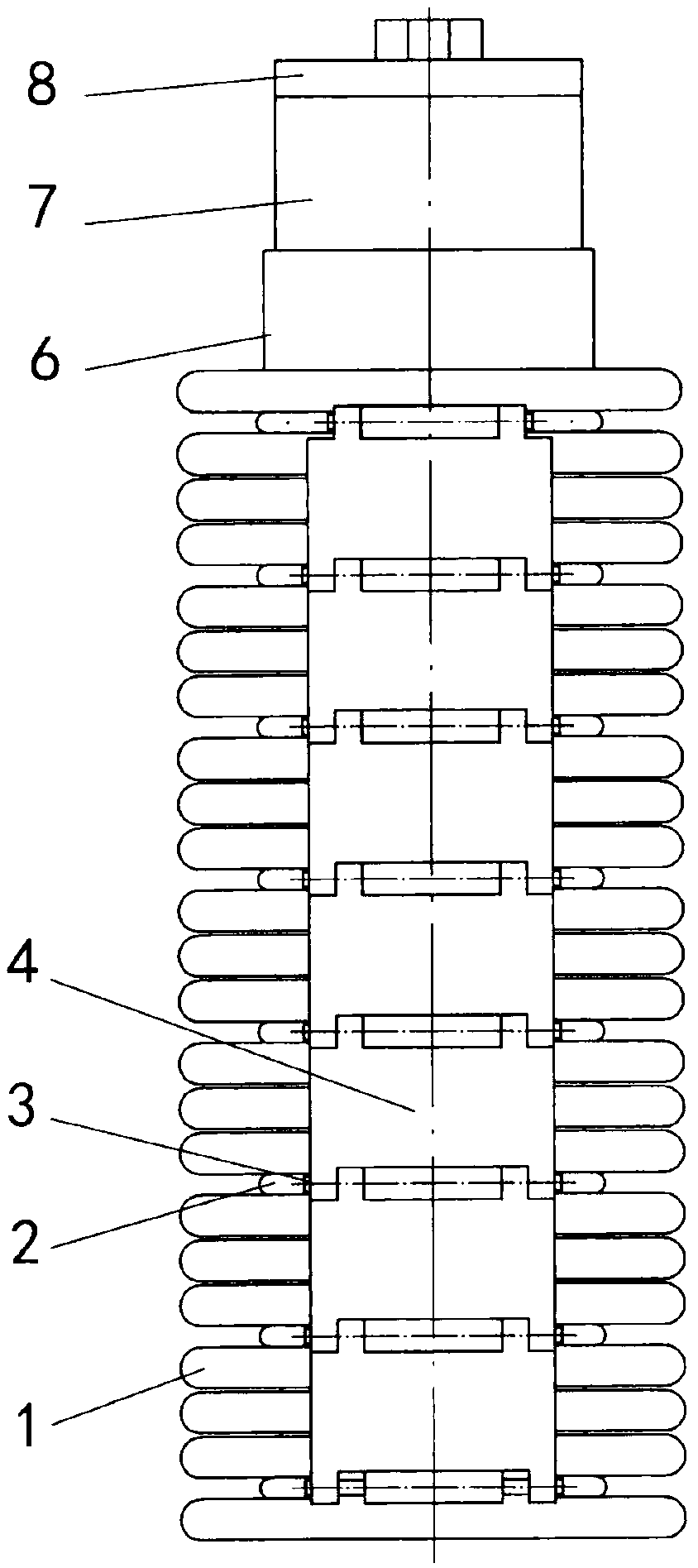

[0030] Such as figure 1 , figure 2 with image 3 As shown, the chain-plate type flexible finger of this embodiment includes an elastic bellows artificial muscle 1, the elastic bellows artificial muscle 1 is a tubular structure with an inner cavity in the middle, its outer wall is corrugated, the top is an open end, and the top open end It is connected with the bellows pipe joint 7 through the clamp 6, the air pipe joint 9 is installed on one side of the bellows pipe joint 7, and the finger mounting plate 8 is fixed on the top surface of the bellows pipe joint 7 by screws; the elastic bellows artificial muscle 1 is corrugated A plastic ring frame 2 is installed in the trough of the outer wall, and a chain plate 4 is installed at the interval between two adjacent plastic ring frames 2, and a plurality of chain plates 4 are arranged in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com