Brake component dismounting device

A technology for dismantling devices and components, which is applied in the field of dismantling devices for brake parts, which can solve the problems of inconvenient disassembly, long time consumption, time-consuming and labor-intensive disassembly of brake parts, etc., and achieve the effect of non-destructive disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

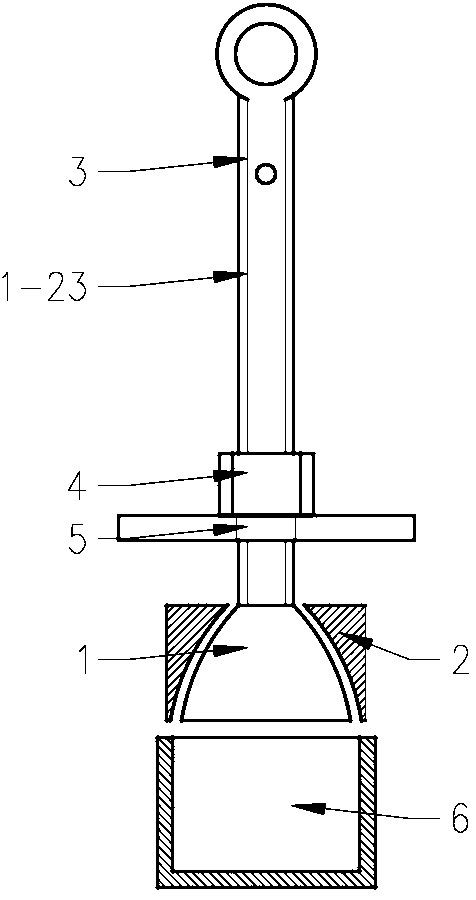

[0015] Such as figure 1 As shown, a brake component disassembly device includes a cone block 1, an expansion block 2, a threaded rod 3, a fastening nut 4, and a limiting plate 5; the cone block 1 is fixedly connected to the bottom end of the threaded rod 3, and the cone block An expansion block 2 is movably connected to the outside of 1 which can be installed inside the brake cylinder 6 after the expansion block 2 and the cone block 1 are installed, and the limiting plate 5 seals the opening of the brake cylinder 6 by tightening the fastening nut 4; Pull the threaded rod 3, the cone block 1 expands the expansion block 2, so that the device and the brake cylinder 6 are connected more firmly.

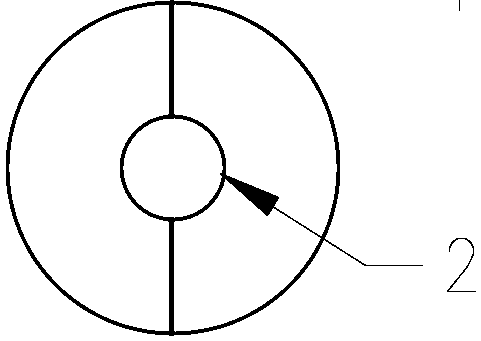

[0016] The expansion block 2 has a two-petal structure, the outside is cylindrical, and the inside is provided with a cone hole that matches the shape and size of the cone block 1. When installed, the expansion block 2 is wrapped around the outside of the cone block.

[0017] The limiting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com