Nonmetallic ore pulverizing mill

A non-metallic ore powder and mill technology, applied in grain processing, etc., can solve the problems of not removing ore impurities online and cannot be completely removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

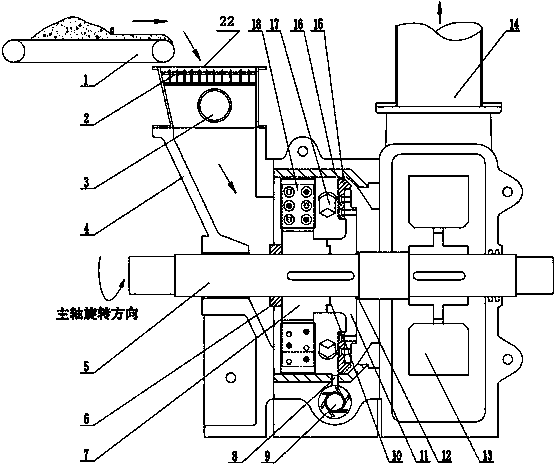

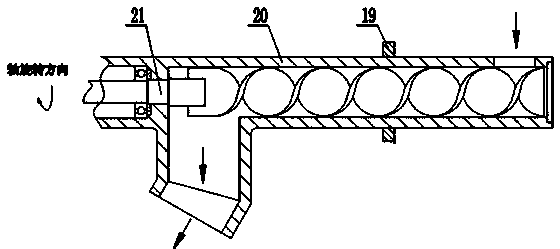

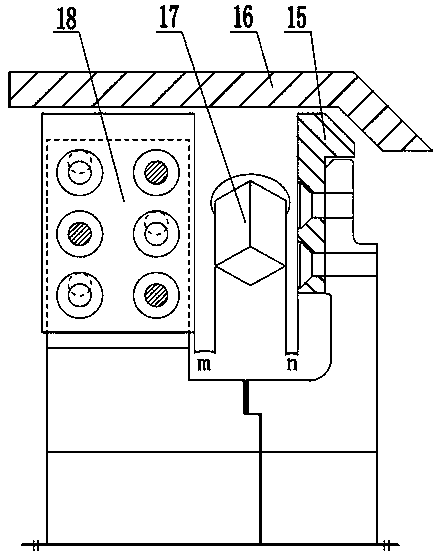

[0019] Such as figure 1 As shown, a non-metallic ore grinding machine includes a feed inlet (22), a grinding chamber, a drive spindle (5), and a mill housing (4). The feed inlet (22) is provided with a Ironware (2), the grinding chamber is located below the feed inlet and communicates with the feed inlet. The grinding chamber consists of a row of rotors (7), a row of hammerheads (18), two rows of rotors (11), two A row of hammerheads (15), a striker (17) and a grinding liner (16), the row of rotors (7) are installed under a row of hammerheads (18) to drive a row of hammerheads to move, and the second row The rotor (11) is installed under the second row of hammerheads (15) to drive the second row of hammerheads to move; the drive spindle (5) is located above the first row of rotors (7) and the second row of rotors (11) to drive the first row of rotors (7) ), the action of the second row of rotors (11); the striker (17) is installed on the outer mill casing (4) between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com