Phosphorous removal and bacterium control type PP cotton filter element and preparation method thereof

A cotton filter and bacteria-type technology, applied in the field of water purification, can solve the problems of high bacterial concentration and a large number of bacteria, and achieve the effects of reducing the total phosphorus concentration, avoiding the increase of bacterial concentration, and inhibiting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

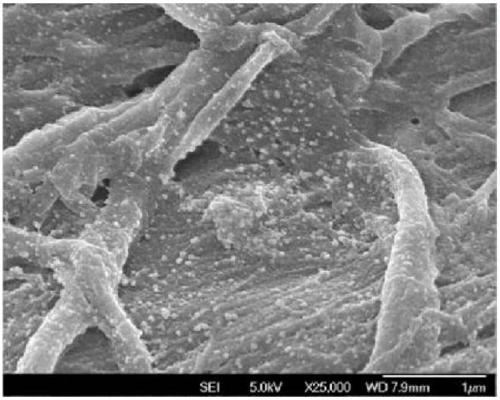

[0029] The preparation method of the above-mentioned phosphorus removal and bacteria control type PP cotton filter element comprises the following steps:

[0030] ⑴. Polypropylene raw materials (particles with a particle size of 0.5-2mm) are melted at a temperature of 166-200°C, and Fe(NO 3 ) 3 ·6H 2 O and La(NO 3 ) 3 ·6H 2 O powder and fully stirred, mechanical stirring speed is controlled at 150-200rpm, polypropylene melt, Fe(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 The mass ratio of O added is 100:(1~10):(1~10);

[0031] (2) Extrude the mixed solution obtained in step (1) through a wire drawing machine, then immerse it in 1-5% sodium hydroxide solution for 5-10 minutes, take it out and dry it to obtain iron lanthanum modified polypropylene fiber filaments, and set aside;

[0032] ⑶. The dry iron lanthanum modified polypropylene fiber obtained in step ⑵ is drawn and pressed to form a tubular filter element. The specifications of the tubular filter element are 5 inches,...

Embodiment 1

[0035] A preparation method for phosphorus removal and bacteria control type PP cotton filter element, the steps comprising:

[0036] ⑴. Polypropylene particles (particles with a particle size of 0.5-2mm) are melted at a temperature of 166°C, and Fe(NO 3 ) 3 ·6H 2 O and La(NO 3 ) 3 ·6H 2 O powder and fully stirred, mechanical stirring speed is controlled at 150rpm, polypropylene particles, Fe(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 The mass ratio of O added is 100:1:1 (the mass of polypropylene particles is 200g, Fe(NO 3 ) 3 ·6H 2 The mass of O is 2g, La(NO 3 ) 3 ·6H 2 The quality of O is 2g);

[0037] ⑵. After the mixed solution is extruded by a wire drawing machine, it is immersed in 1% sodium hydroxide solution for 5 minutes, taken out and dried, and set aside;

[0038](3) The dry iron-lanthanum-modified polypropylene fiber obtained in step (2) is drawn and pressed into a 5-inch tubular filter element.

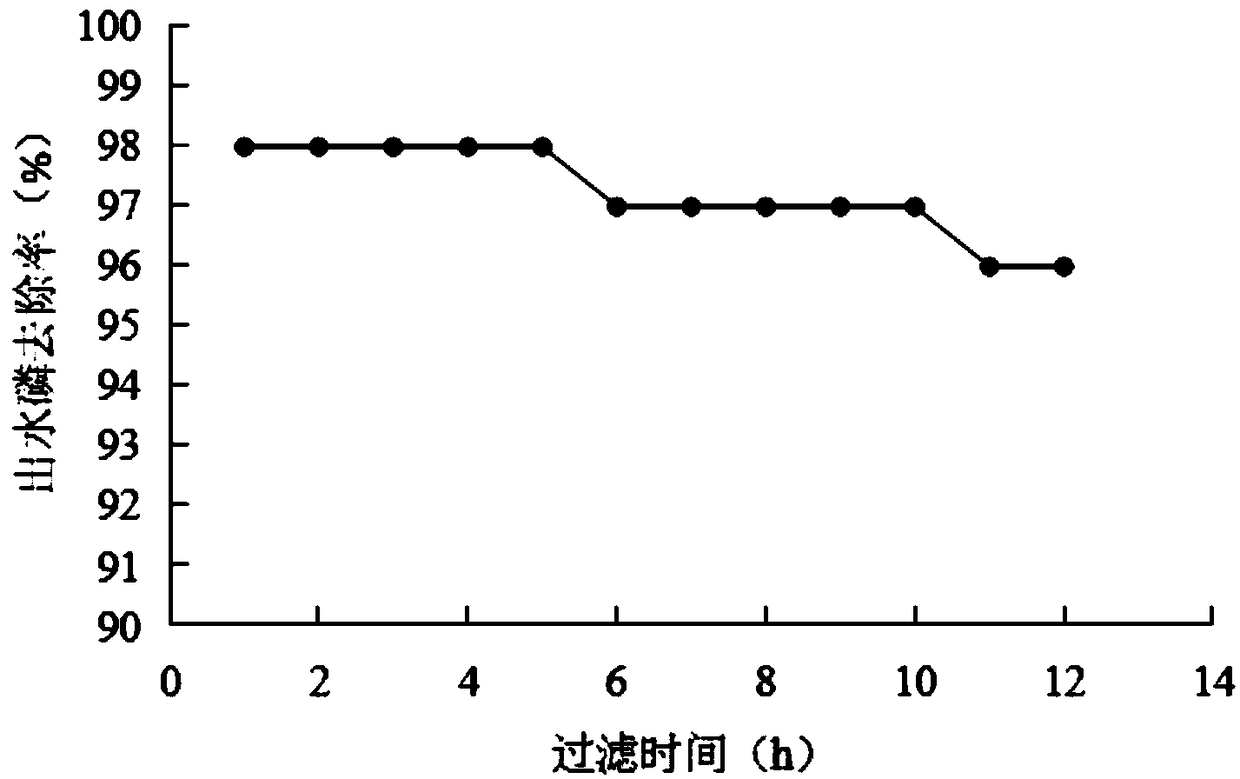

[0039] The municipal tap water in Tianjin Binhai New Are...

Embodiment 2

[0041] A preparation method for phosphorus removal and bacteria control type PP cotton filter element, the steps comprising:

[0042] ⑴. Polypropylene particles (particles with a particle size of 0.5-2mm) are melted at a temperature of 180°C, and Fe(NO 3 ) 3 ·6H 2 O and La(NO 3 ) 3 ·6H 2 O powder and fully stirred, mechanical stirring speed is controlled at 200rpm, polypropylene particles, Fe(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 The mass ratio of O added is 100:5:1 (the mass of polypropylene particles is 200g, Fe(NO 3 ) 3 ·6H 2 The mass of O is 10g, La(NO 3 ) 3 ·6H 2 The quality of O is 2g);

[0043] ⑵. After the mixed solution is extruded by a wire drawing machine, it is immersed in 2% sodium hydroxide solution for 10 minutes, taken out and dried, and set aside;

[0044] ⑶. The dry iron lanthanum modified polypropylene fiber obtained in step ⑵ is drawn and pressed to form an 8-inch tubular filter element.

[0045] The municipal tap water in Tianjin Binhai New...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com