Coconut milk and preparation method

A technology of coconut milk and coconut milk, which is applied in the field of coconut milk and its preparation, can solve the problems of loss of nutrients in coconut milk, poor product stability, loss of nutrients in coconut milk, etc., to retain nutrients, increase stability, and increase fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides the preparation method of the described coconut milk of above-mentioned scheme, comprises the following steps:

[0033] 1) Carry out the first filtration and the second filtration successively to the coconut milk to obtain refined coconut milk;

[0034] 2) mixing refined coconut milk, water, white granulated sugar, gum arabic, glycerin fatty acid ester, polysorbate and sorbitan monopalmitate, and performing high-pressure homogenization to obtain a mixture;

[0035] 3) performing the first depressurization treatment and the second depressurization treatment on the mixed material in the step 2) successively to obtain the intermediate material;

[0036] 4) Sterilize the intermediate material in the step 3) to obtain coconut milk.

[0037] In the present invention, the first filtration and the second filtration are carried out successively to the coconut milk to obtain refined coconut milk; the mode of the first filtration is filter screen fi...

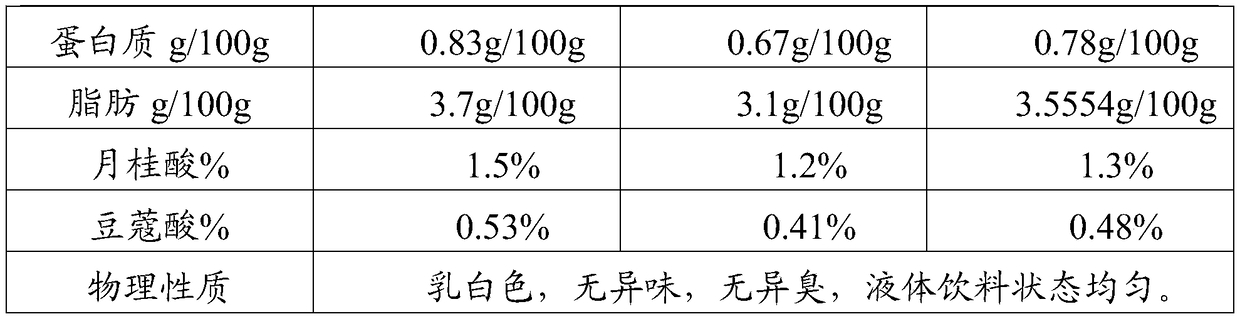

Embodiment 1

[0045] 1) Squeeze the coconut milk: squeeze the coconut meat through a screw press to extract the coconut milk. The pressing temperature is 36.5° C., the pressing time is 7 minutes, and the pressure is 158 MPa.

[0046] 2) Filtration: Two times of filtration are adopted, the first filtration is 70 mesh, and the second filtration is 150 mesh sieve to remove particles;

[0047] 3) Mixed material: Dissolve various ingredients in hot water at 75°C, and the mixing and dissolving time is 35 minutes;

[0048] 4) High-pressure homogenization: the set pressure is 30Mpa, and the feed liquid is homogenized for 15 minutes at a speed of 8000-10000r / min;

[0049] 5) Deodorization: carry out depressurization treatment, the first depressurization to 15Mpa, depressurization treatment time: 17min. The second time of complete depressurization, the depressurization treatment time is: 8min, to remove the peculiar smell;

[0050] 6) Pasteurization: Sterilize at 70° C. for 10 minutes to obtain co...

Embodiment 2

[0052] 1) Squeeze the coconut milk: squeeze the coconut meat through a screw press to extract the coconut milk. The pressing treatment temperature is 32° C. and the pressing treatment time is 5 minutes; the pressure is 13 Mpa.

[0053] 2) Filtration: Two filtrations are adopted, the first filtration is 60 mesh, and the second filtration is 140 mesh sieve to remove particles;

[0054] 3) Mixed material: Dissolve various ingredients in hot water at 70°C, and the mixing and dissolving time is 32 minutes;

[0055] 4) High-pressure homogenization: the set pressure is 31Mpa, and the feed liquid is homogenized for 10 minutes at a speed of 8000-10000r / min;

[0056] 5) Deodorization: carry out depressurization treatment, the first depressurization to 20Mpa, depressurization treatment time: 15min. The second time of complete decompression, the decompression treatment time is: 5min, to remove the peculiar smell;

[0057] 6) Pasteurization: Sterilize at 65° C. for 8 minutes to obtain c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com