Remote monitoring system

A technology of remote monitoring system and remote controller, applied in general control system, control/adjustment system, program control, etc., can solve the problems of support machine maintenance time, idle working time, cost waste, etc., to reduce time and the effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

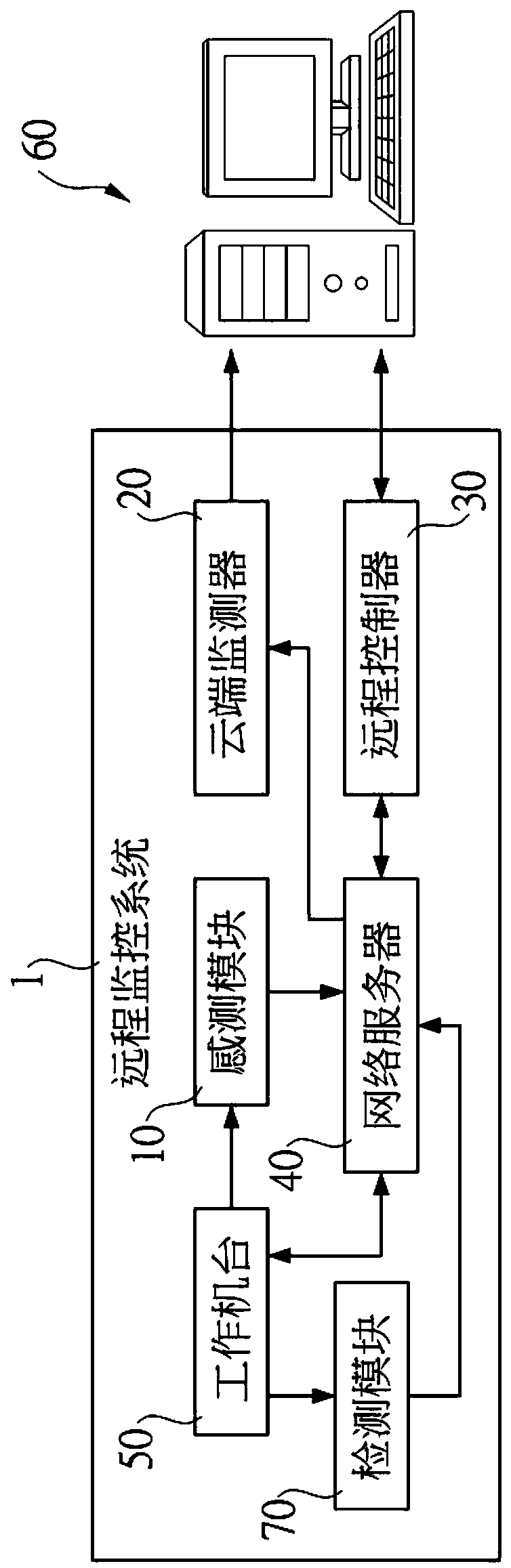

[0043]The present invention provides a remote monitoring system 1 for remote control of factory machines, maintenance and repair, and automatic writing of product yield in a manufacturing factory, which can greatly reduce manpower.

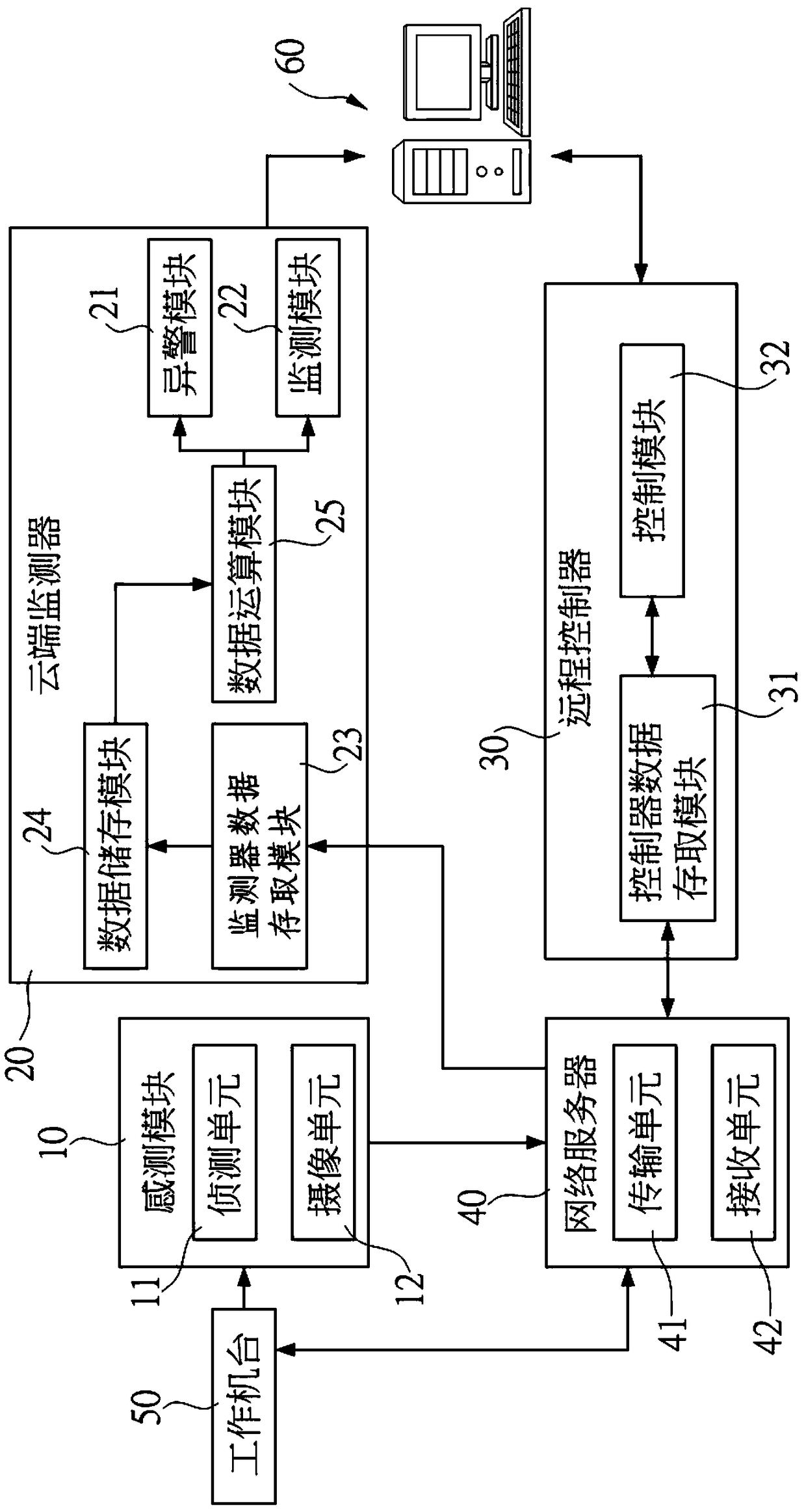

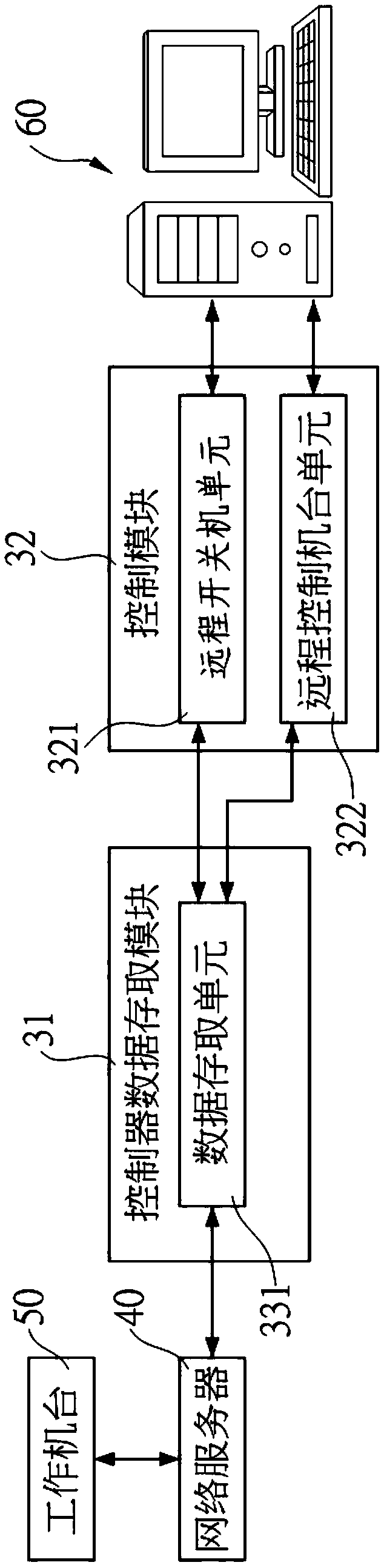

[0044] according to Figure 1 to Figure 2 As shown, a remote monitoring system 1 includes: several working machines 50, an external access device 60, a sensing module 10, a cloud monitor 20, a remote controller 30 and a network server 40, The network server 40 links the plurality of working machines 50, the sensing module 10, the cloud monitor 20 and the remote controller 30, and the cloud monitor 20 and the remote controller 30 are connected to the external access device 60 The sensing module 10 has a detection unit 11, the detection unit 11 detects the several working machines 50 to generate machine status signals and transmits them to the network server 40, the sensing module 10 also has a camera unit 12. The camera unit 12 captures the monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com