Marine solid oxide fuel cell and steam-injected gas turbine combined generating system and marine solid oxide fuel cell and steam-injected gas turbine combined generating method

A technology of solid oxides and fuel cells, which is applied in the direction of fuel cells, fuel cell additives, gas turbine devices, etc., and can solve problems such as wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

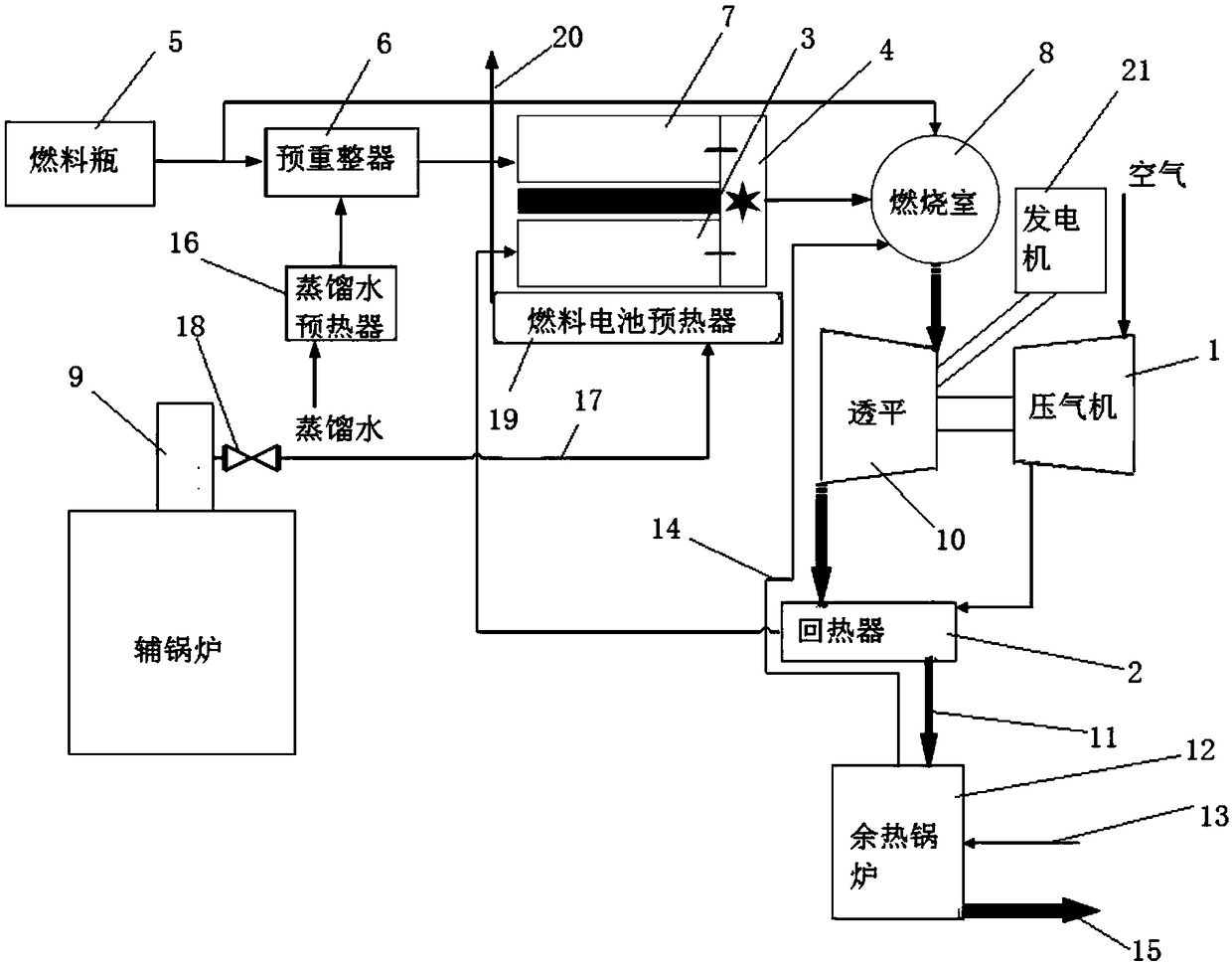

[0019] A combined power generation system of a marine solid oxide fuel cell and a steam injection gas turbine designed by the present invention, such as figure 1 As shown, it includes a compressor 1, a regenerator 2, a solid oxide fuel cell, a fuel bottle 5, a pre-reformer 6, a combustion chamber 8, a turbine 10, a waste heat boiler 12, and a distilled water preheater 16, wherein, The air input port of the compressor 1 is used to feed air, the air output port of the compressor 1 is connected to the gas input end of the regenerator 2, and the gas output end of the regenerator 2 is connected to the cell stack cathode 3 of the solid oxide fuel cell (The regenerator 2 heats the air), the fuel output end of the fuel bottle 5 is connected to the fuel input end of the pre-reformer 6, the input end of the distilled water preheater 16 is used to import d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com