Rail anti-torsion limit rail lower pad plate used for a fastening system

A technology of under-rail pads and limit baffles, which is applied in the field of rail transit, can solve problems such as long-term train running threats, deterioration of the environment along the line, and impact on ride comfort, so as to eliminate hidden dangers of train operation, reduce noise and environmental pollution. Noise pollution, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

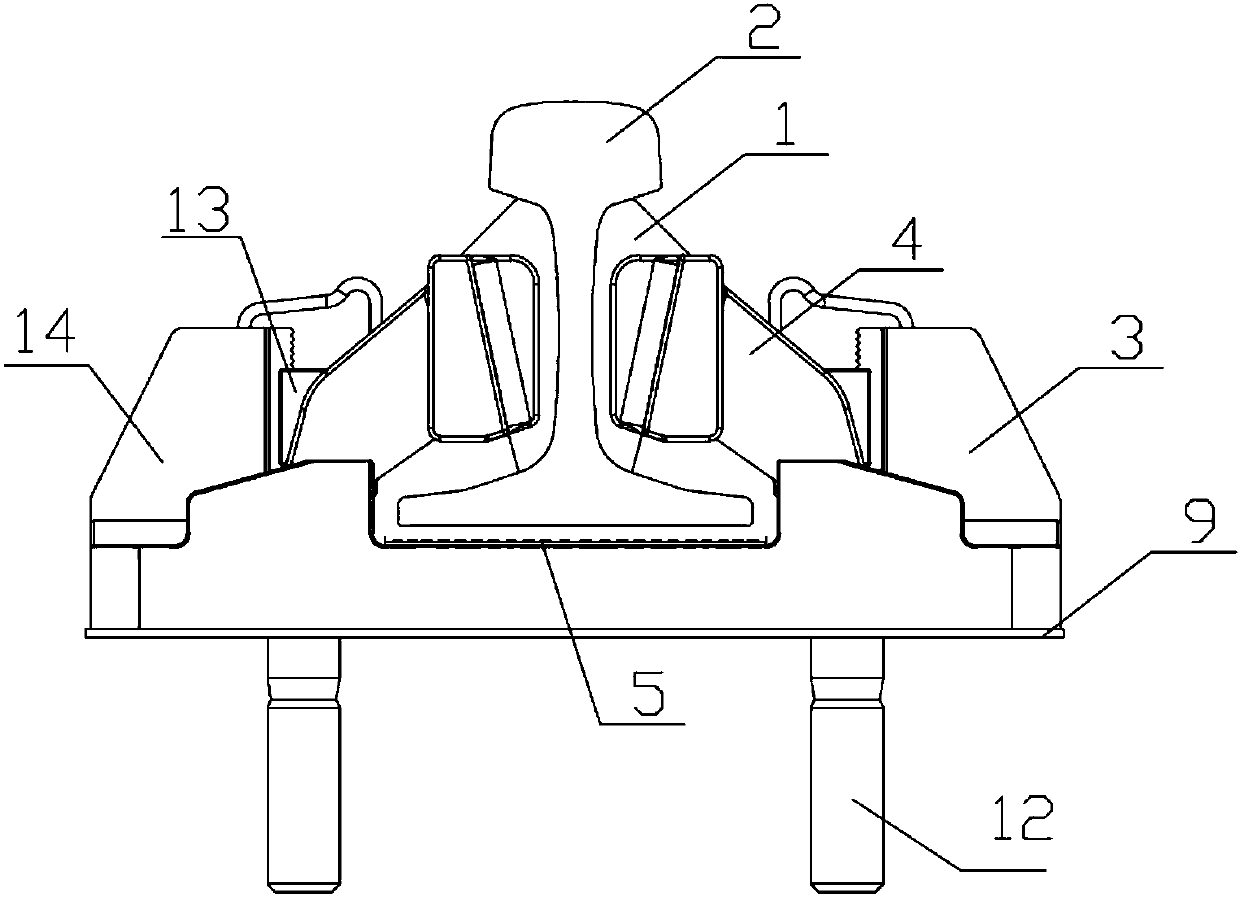

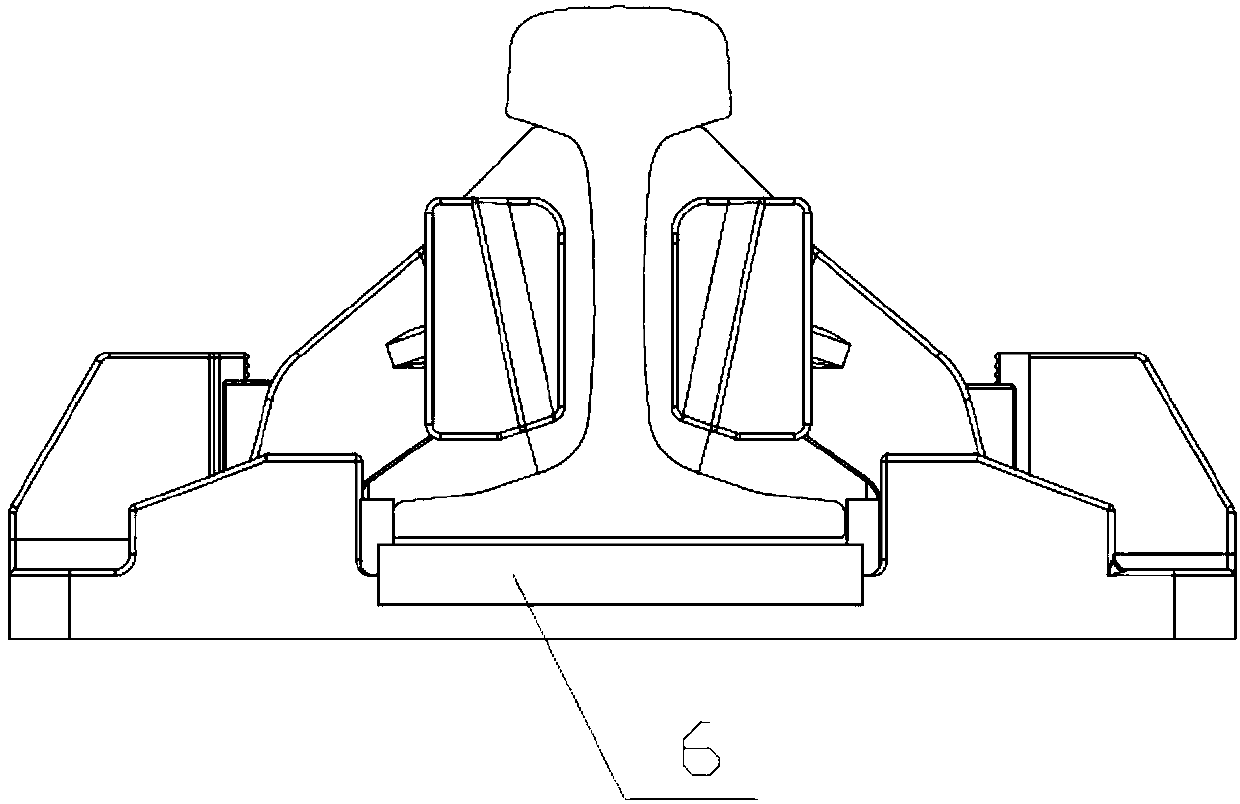

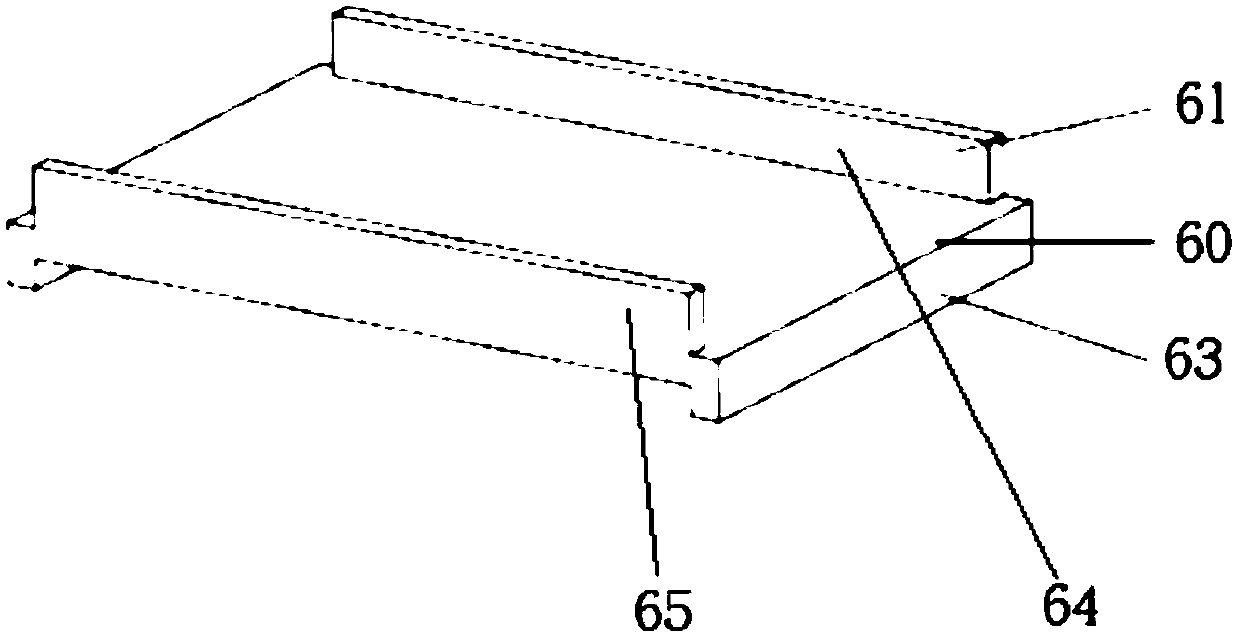

[0038] Such as figure 2 , the present invention provides an under-rail backing plate 6, the under-rail backing plate 6 replaces the anti-collision backing plate 5 in the prior art and is installed between the rail 2 and the bottom plate 3. Such as image 3 As shown, the under-rail backing plate 6 includes a base plate 60 , and the base plate 60 is rectangular. A group of opposite side edges of the base plate 60 is provided with a limit protrusion 61, and the limit protrusion 61 is perpendicular to the base plate 60; another set of opposite side edges is provided with a positioning protrusion 63 perpendicular to the base plate 60; The protruding directions of the positioning protrusions 61 and the positioning protrusions 63 relative to the substrate 60 are opposite. The base plate 60 and the limiting protrusion 61 form a groove-shaped structure, and accommodate the rail foot of the steel rail 2 in the groove-shaped structure. The side of the position-limiting protrusion 61 ...

Embodiment 2

[0046] The second embodiment mainly describes the embodiment of the structure of the under-rail backing plate 6 which is vulcanized by steel plate and rubber.

[0047] Such as Figure 4-Figure 6 , the substrate 60 is vulcanized by steel plate and rubber, and the substrate 60 includes three layers, wherein the upper layer 601 and the lower layer 603 are rubber, and the middle layer 602 is steel plate. Limiting protrusion 61 is also vulcanized by steel plate and rubber. Such as Figure 4-Figure 5 , the position-limiting protrusion 61 is set as two layers, the inner layer 612 is a steel plate, and the outer layer 611 is rubber. As a whole, the overall strength of the substrate 60 and the position-limiting protrusion 61 is enhanced; or the inner layer 612 is rubber, and the outer layer 611 is a steel plate. Preferably, the inner layer 612 and the outer layer 611 of the position-limiting protrusion 61 are respectively connected to the The upper layer 601 and the middle layer 602...

Embodiment 3

[0053] The third embodiment mainly describes the structure of the limit block 31 on the bottom plate 3 . Such as Figure 17-21 , the middle area of the bottom plate 3 is provided with a recessed portion, and a limit block 31 is provided near a pair of opposite sides of the recessed portion perpendicular to the rail direction. Such as Figure 17 and Figure 19 , keeping a certain distance from the edge of the recessed part, a limit block 31 is set on the bottom plate 3, and the stop block 31 can be a wedge-shaped block or a strip block; the limit block 31 is adjacent to the edge of the recessed part The second inner side 311 is perpendicular to the bottom plate 3 and parallel to the edge of the adjacent recessed portion. Such as Figure 18 , the second inner surface of the limiting block 31 is perpendicular to the bottom plate 3 , and the limiting block 31 shares a side wall with the adjacent recessed portion. Such as Figure 20 , for the fastener system with shoulders,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com