Physical method for compatibilizing direct coal liquefaction residue modified asphalt

A technology of direct coal liquefaction and modified asphalt, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of restricting the application of DCLR, little research, and the decline of asphalt's low-temperature performance, so as to improve compatibility, The effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

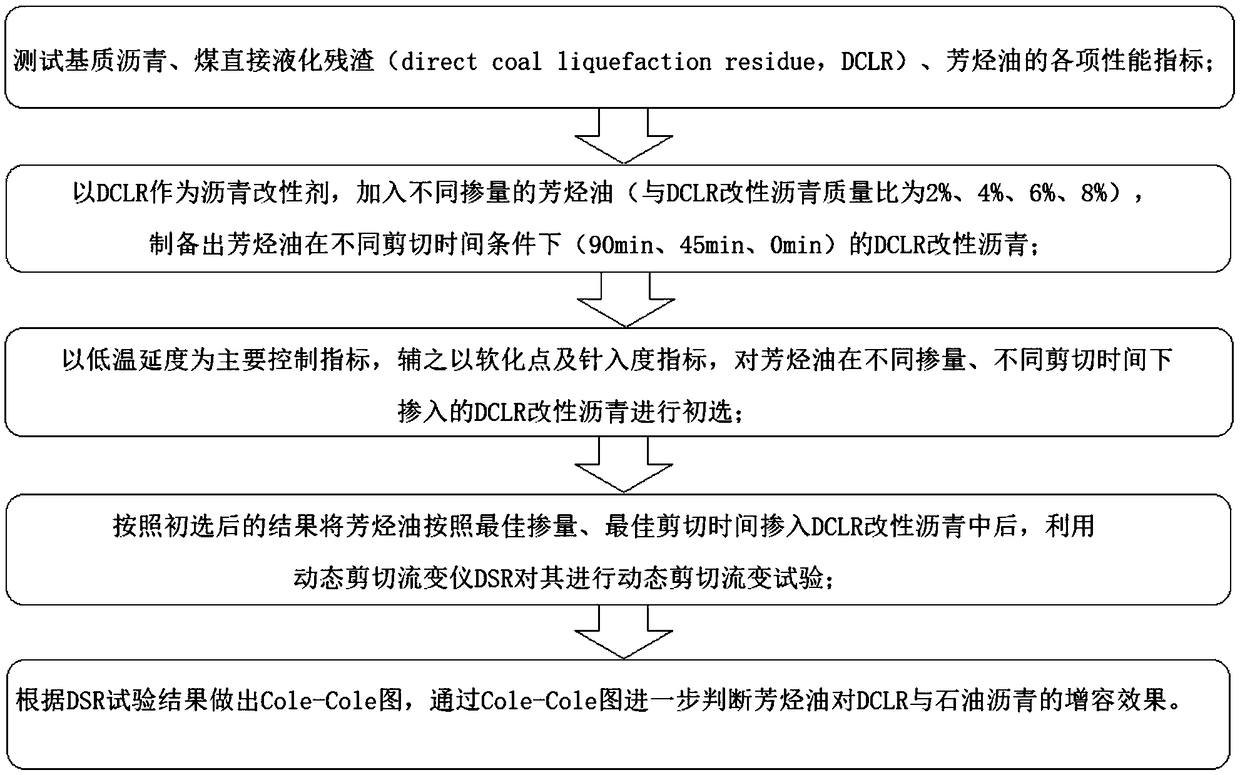

Image

Examples

Embodiment 1

[0056] The technical indicators of DCLR, base asphalt (Shell-90) and aromatic oil were tested, and the results are shown in Table 1, Table 2 and Table 3.

[0057]

[0058] Table 1

[0059]

[0060] Table 2

[0061]

[0062] table 3

[0063] Table 1 Properties of DCLR, Table 2 Properties of Base Bitumen (Shell-90), Table 3 Properties of Aromatic Oil.

[0064] 12 kinds of DCLR modified asphalt samples were prepared by cross-combining 4 different dosages (2%, 4%, 6%, 8%) and 3 mixing methods (aromatic oil shear time: 90min, 45min, 0min) , to test the three major indicators, as shown in Table 4.

[0065]

[0066] Table 4

[0067] Table 4 records the basic properties of DCLR modified asphalt after adding aromatic oil.

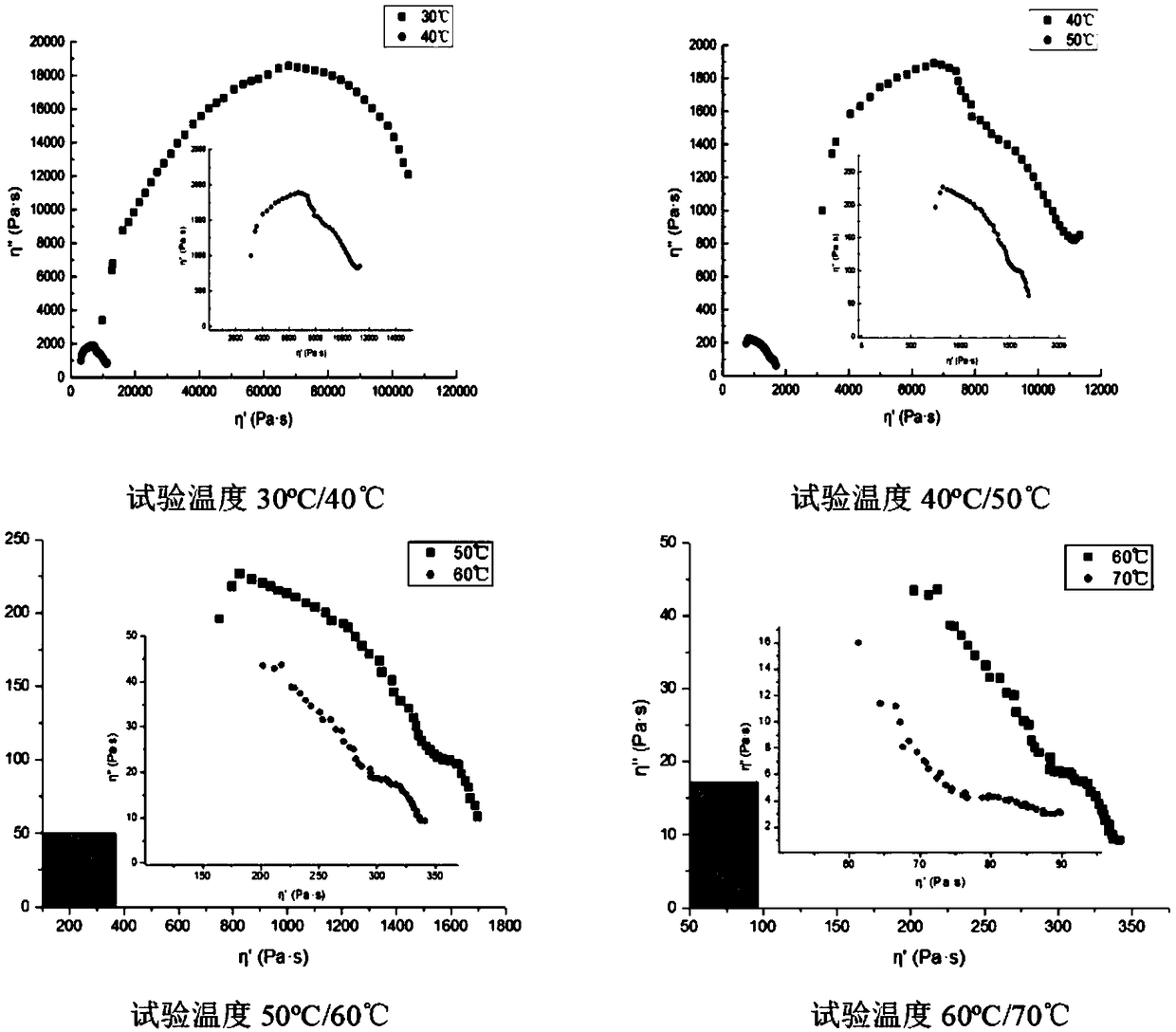

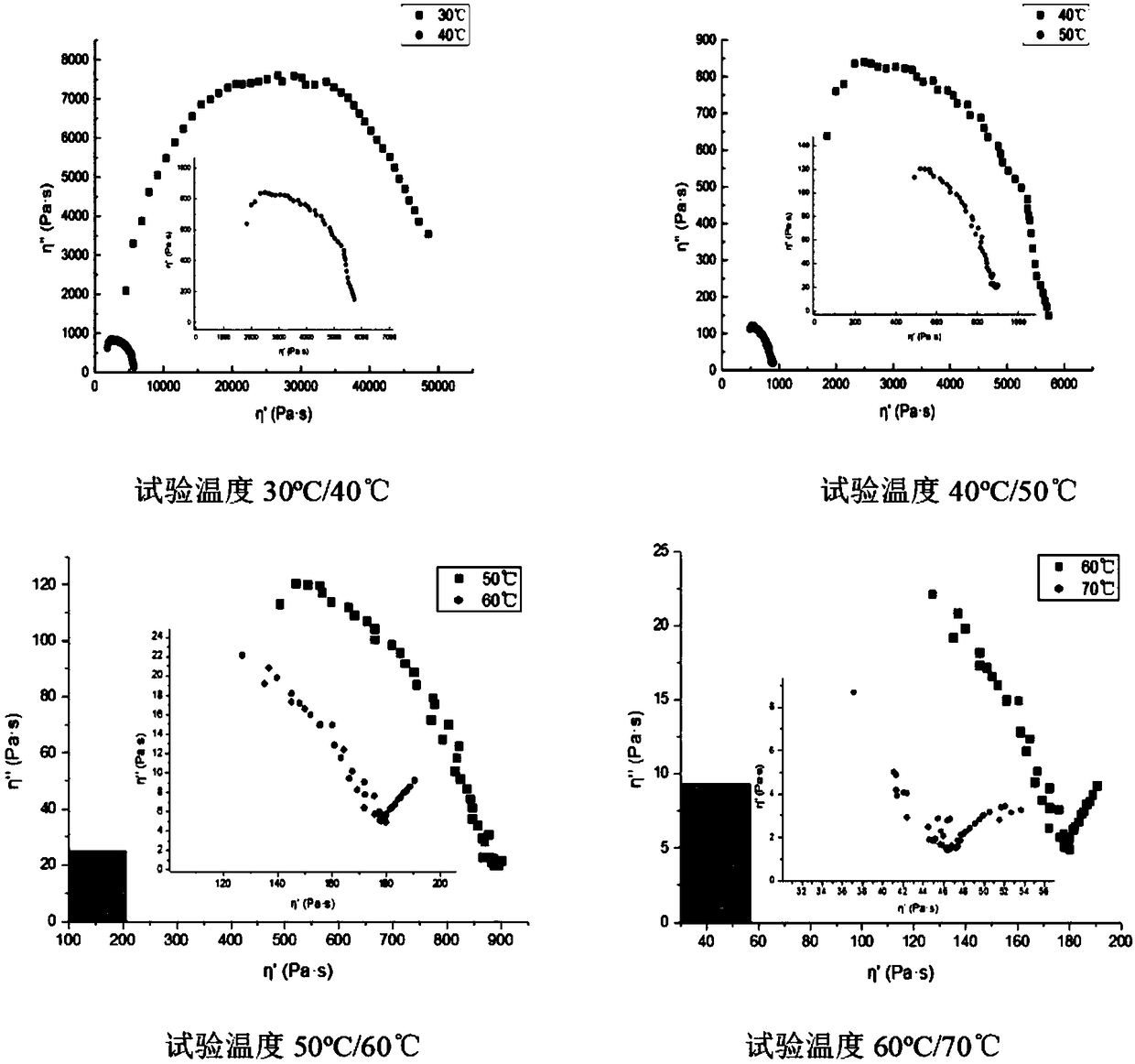

[0068] Taking the low temperature ductility as the main control index, supplemented by the softening point and penetration index, through the range analysis of the above test results, the DCLR modified asphalt mixed with aromatic oil at different do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com