Composite hydrogel, preparation method and application thereof

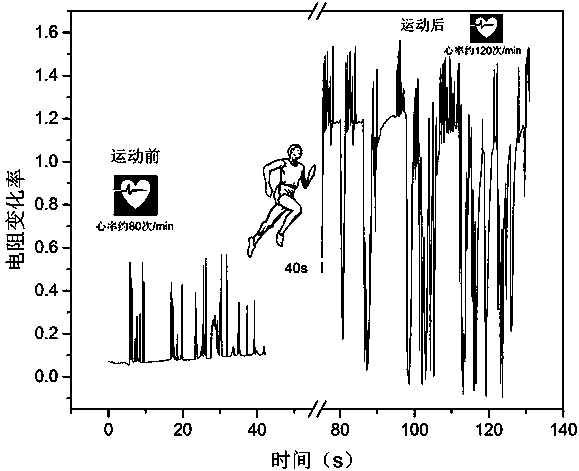

A composite hydrogel, hydrogel technology, applied in applications, sensors, measurement of pulse rate/heart rate, etc., to achieve the effect of good strain-responsive electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

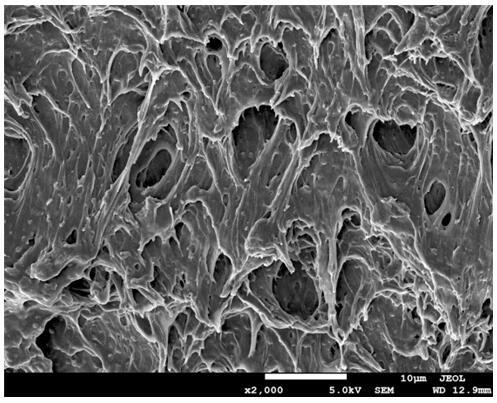

Image

Examples

Embodiment 1

[0031] A method for preparing a double-network hydrogel strain sensing patch with electrical conductivity, the specific preparation process includes the following steps:

[0032] ①Preparation of polyvinyl alcohol single network hydrogel embedded with CMC and monomer Py: mix the PVA solution (10.5mL) with a concentration of 0.1g / mL and the CMC solution (5.5mL) with a concentration of 0.04g / mL , and keep the solution temperature at 95°C, magnetic stirring to mix the two evenly, add 100 μL of HCl solution with a concentration of 20% to the mixed solution, adjust the pH to 4.0, and then add pyrrole (Py) with a concentration of 0.5mol / L The solution was 0.5 mL and stirred for 30 min. After the solution was uniformly mixed, an aqueous solution of glutaraldehyde (0.38 mL) with a concentration of 4.0 mg / mL (0.38 mL) was added, and the mixture was stirred uniformly. Polyvinyl alcohol single network hydrogel of CMC and monomer Py;

[0033] ②PPy / CMC-Fe 3+ / PVA composite hydrogel prepar...

Embodiment 2

[0038] A method for preparing a double-network hydrogel strain sensing patch with electrical conductivity, the specific preparation process includes the following steps:

[0039] ① Preparation of polyvinyl alcohol single-network hydrogel embedded with CMC and monomer Py: mix the PVA solution (10.5 mL) with a concentration of 0.15 g / mL and the CMC solution (5.5 mL) with a concentration of 0.05 g / mL , and keep the solution temperature at 95°C, magnetic stirring to mix the two evenly, add 200 μL of HCl solution with a concentration of 20% to the mixed solution, adjust the pH to 4.0, and then add pyrrole (Py) with a concentration of 1.0mol / L The solution was 0.5 mL and stirred for 30 min. After the solution was uniformly mixed, an aqueous solution of glutaraldehyde (0.38 mL) with a concentration of 5.0 mg / mL (0.38 mL) was added, stirred evenly, and the mixed solution was poured into a mold and reacted in a water bath at 60°C for 50 min to obtain the Polyvinyl alcohol single networ...

Embodiment 3

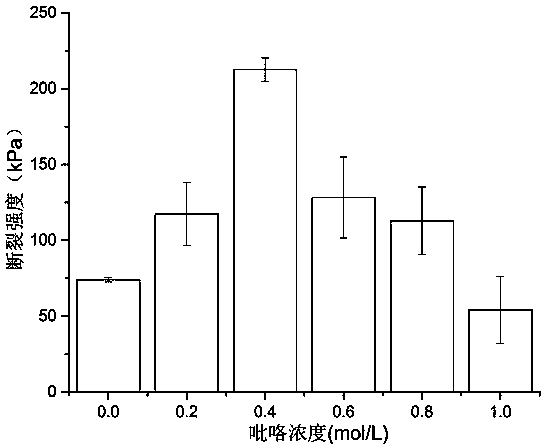

[0043] The preparation process is the same as in Example 1. This example provides PPy / CMC-Fe prepared under different pyrrole concentrations. 3+ / PVA composite hydrogel, and its performance was tested, such as image 3 , Figure 4 shown. The pyrrole concentrations were 0mol / L, 0.2mol / L, 0.4mol / L, 0.6mol / L, 0.8mol / L, and 1.0mol / L, respectively.

[0044] Determination of prepared PPy / CMC-Fe with Instron3343 3+ / PVA composite hydrogel mechanical properties (Instron3343: USA, loading rate: 30mm / min). Determination of the prepared polypyrrole / sodium carboxymethylcellulose-Fe with Keithley 2400 digital source meter 3+ / PVA composite hydrogel under different strains and actual application conditions (R), and convert it to the change rate of resistance (R-R 0 / R 0 ×100%).

[0045] image 3 It is the obtained PPy / CMC-Fe prepared under the conditions of the pyrrole concentration of 0mol / L, 0.2mol / L, 0.4mol / L, 0.6mol / L, 0.8mol / L and 1.0mol / L respectively 3+ / PVA composite hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com