Small connecting lever insulated overhead working truck cantilever crane and control system thereof

A high-altitude operating vehicle and control system technology, applied in the field of aerial operating vehicles, can solve the problems of large pressure loss, many pipelines in the arm, large load and space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

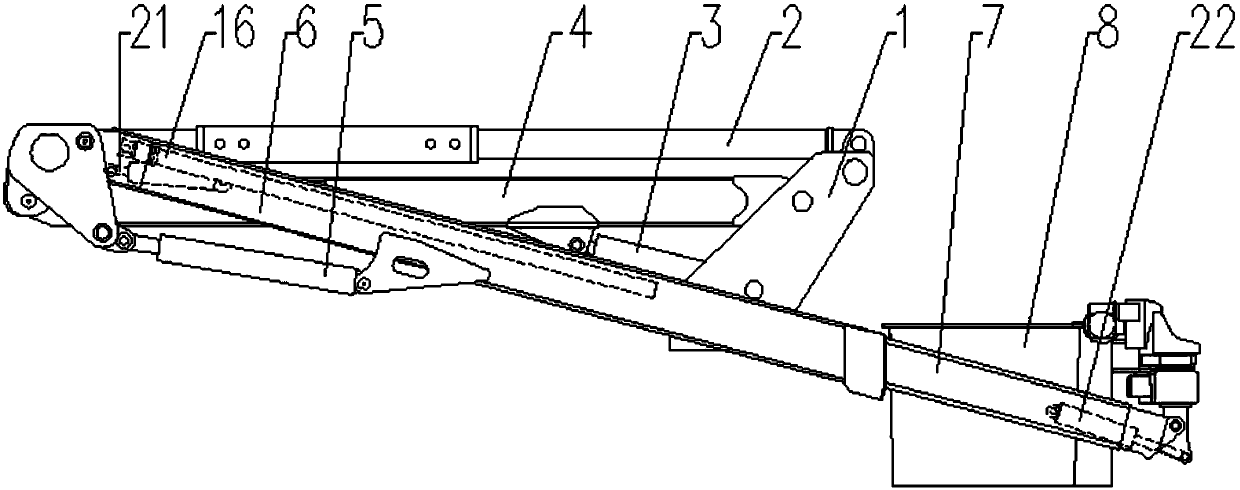

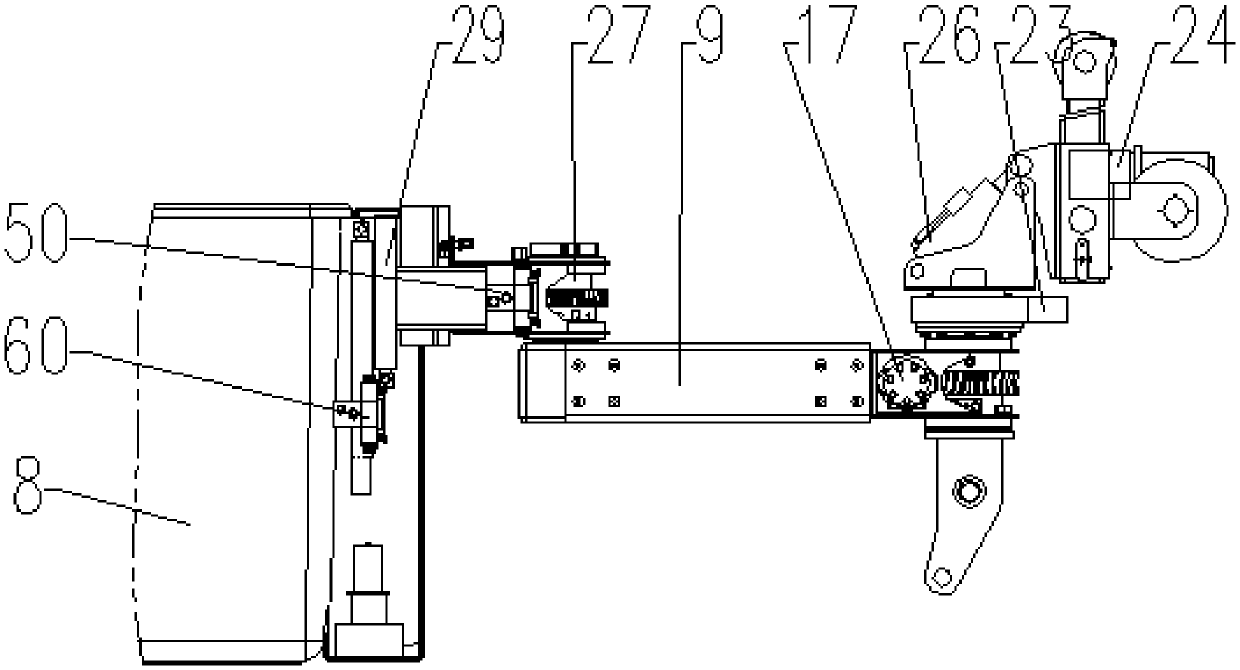

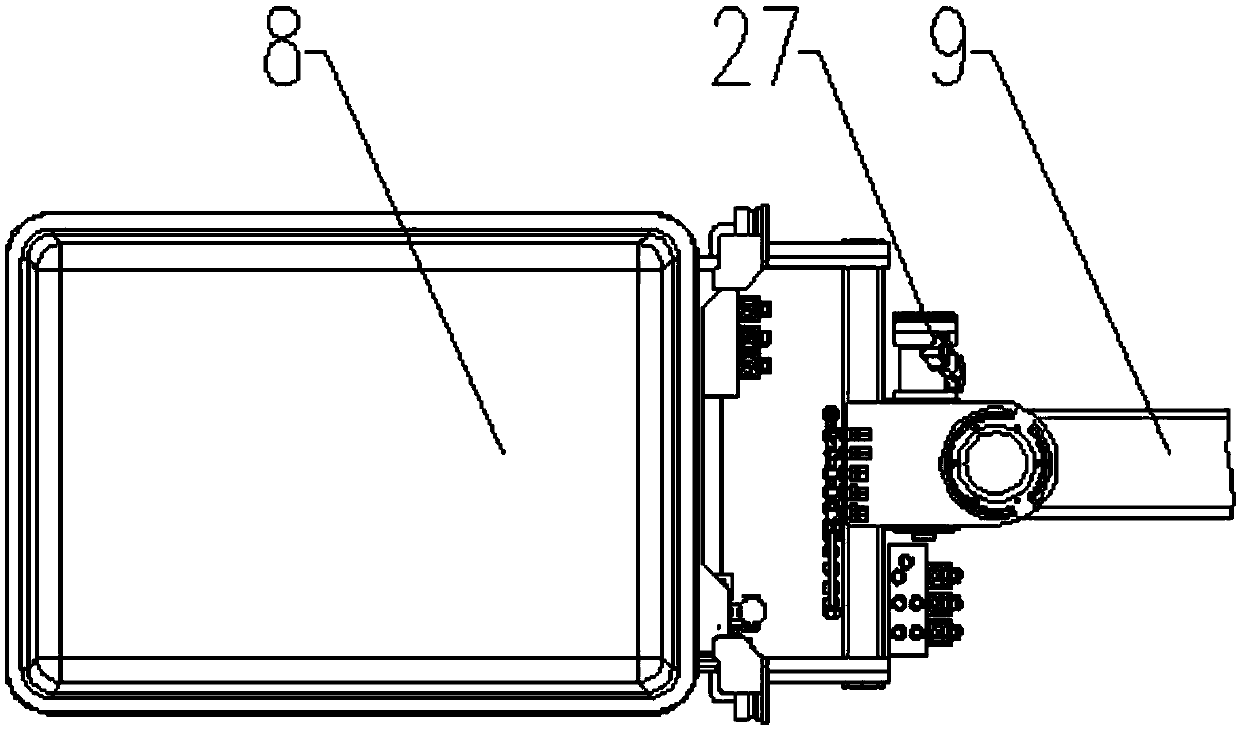

[0040] Such as Figure 4 As shown in the figure, a control system for the jib frame of a small crank insulated aerial work vehicle includes the active control circuit of the jib. The active control circuit of the jib includes a hydraulic pump, a main control proportional valve group 30 for the turntable, a rotary motor 12 for the turntable, and a lower arm control circuit. The lifting cylinder 3, the upper arm lifting cylinder 5 and the upper arm telescopic cylinder 16 can realize the precise control of boom rotation, lower arm lifting, upper arm lifting and upper arm telescopic movement through the operation of each action control valve of the main control proportional valve group 30 of the turntable; It is characterized in that it also includes a platform auxiliary action circuit and a platform power generation control circuit. The platform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com