An automatic creasing closing system

An automatic, indentation technology, applied in the field of automation, can solve the problems that the connection reliability is difficult to meet the multi-frequency repeated work, affects the installation adaptability, and the product performance is unstable, so as to achieve effective and reliable connection, easy function, and reduced The effect of increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

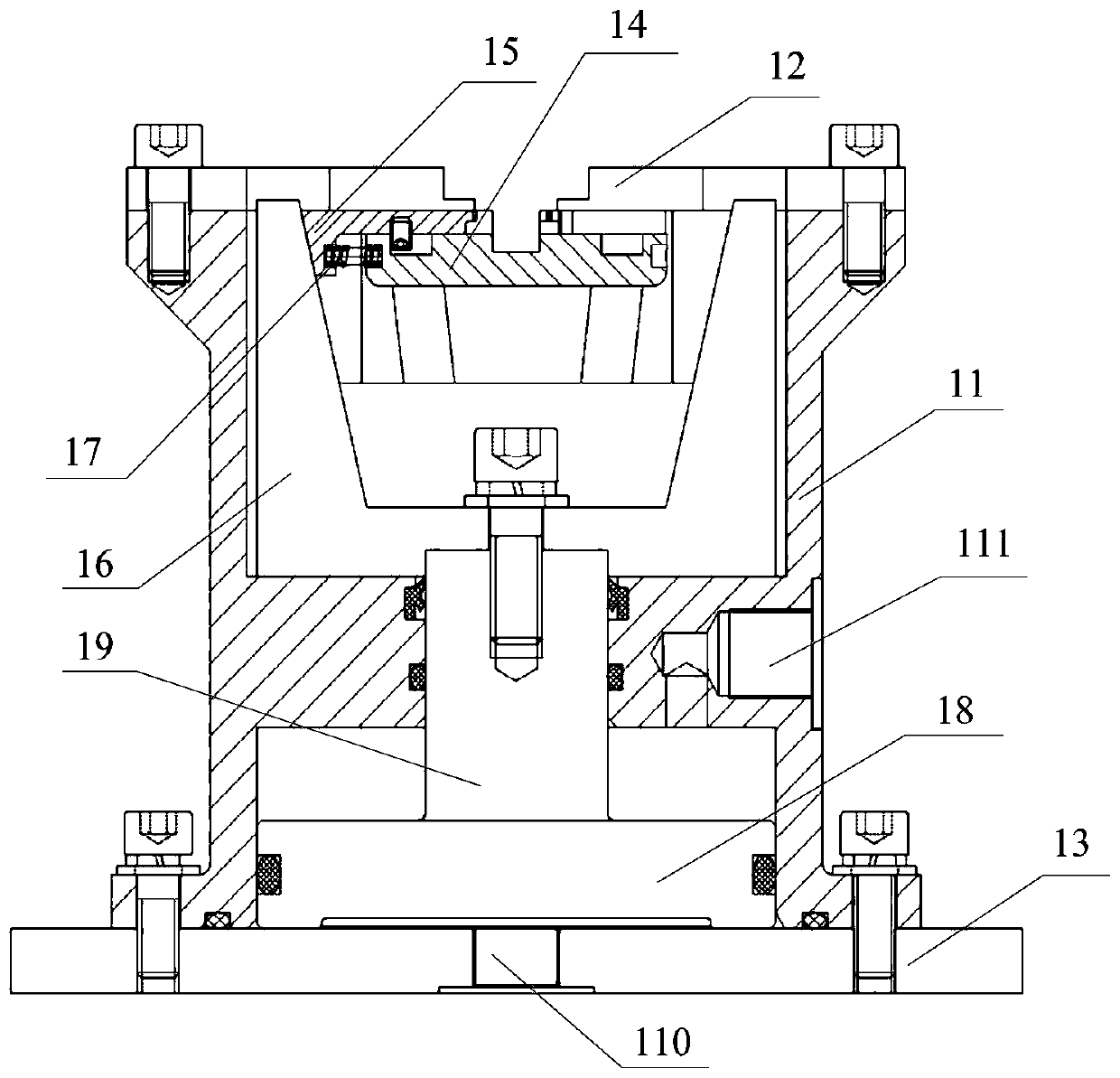

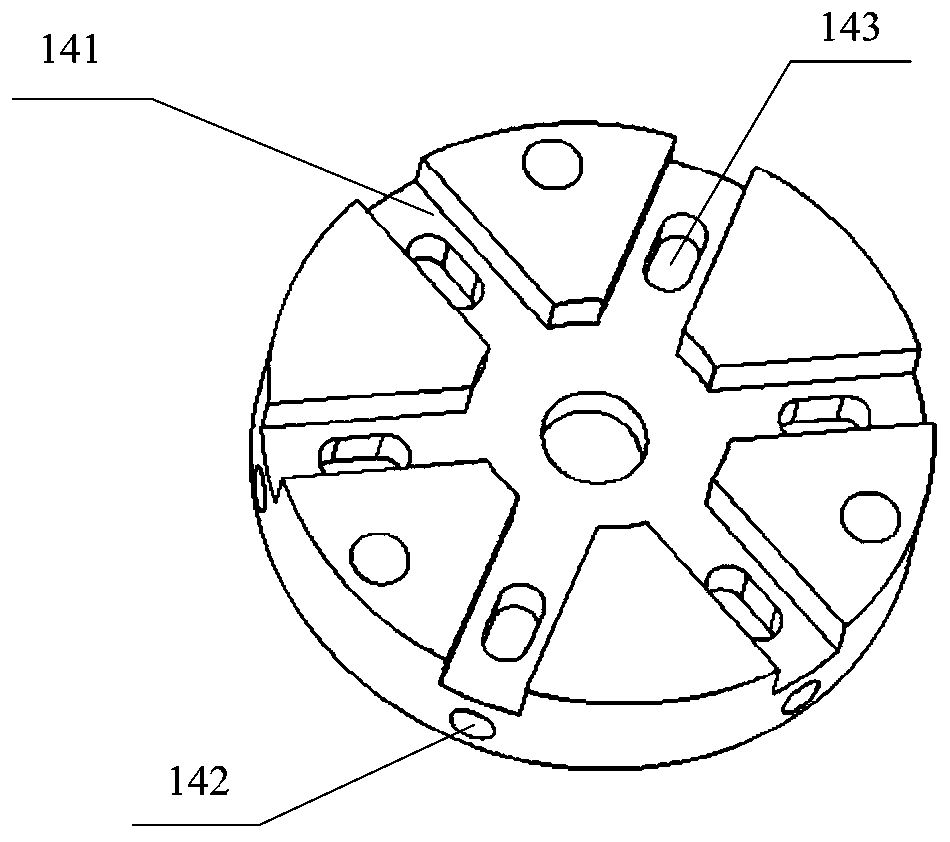

[0021] This application discloses an automatic indentation closing system, please refer to figure 1 The structural diagram of the system is shown, the system includes a closing machine 10, a hydraulic oil pipe 20 and a hydraulic station 30, the closing machine 10 includes two oil ports, and these two oil ports are respectively connected to the hydraulic station 30 through two hydraulic oil pipes 20, The hydraulic station 30 is an existing commonly used hydraulic system, which can hydraulically control the necking machine 10 . In actual operation, the system also includes a workbench 40, the mouth closing machine 10 is arranged on the workbench 40, the hydraulic station 30 is placed under the workbench 40, and the electric control switch of the hydraulic station 30 can be arranged on the workbench 40. The setting method is safe and easy to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com