Cooking utensil

A technology for cooking utensils and air intake pipes, which is applied to the covers of cooking utensils, cooking utensils, household utensils, etc., can solve the problems of residues, agglomeration, hanging on the wall, rice and other materials that are difficult to enter into the pot, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

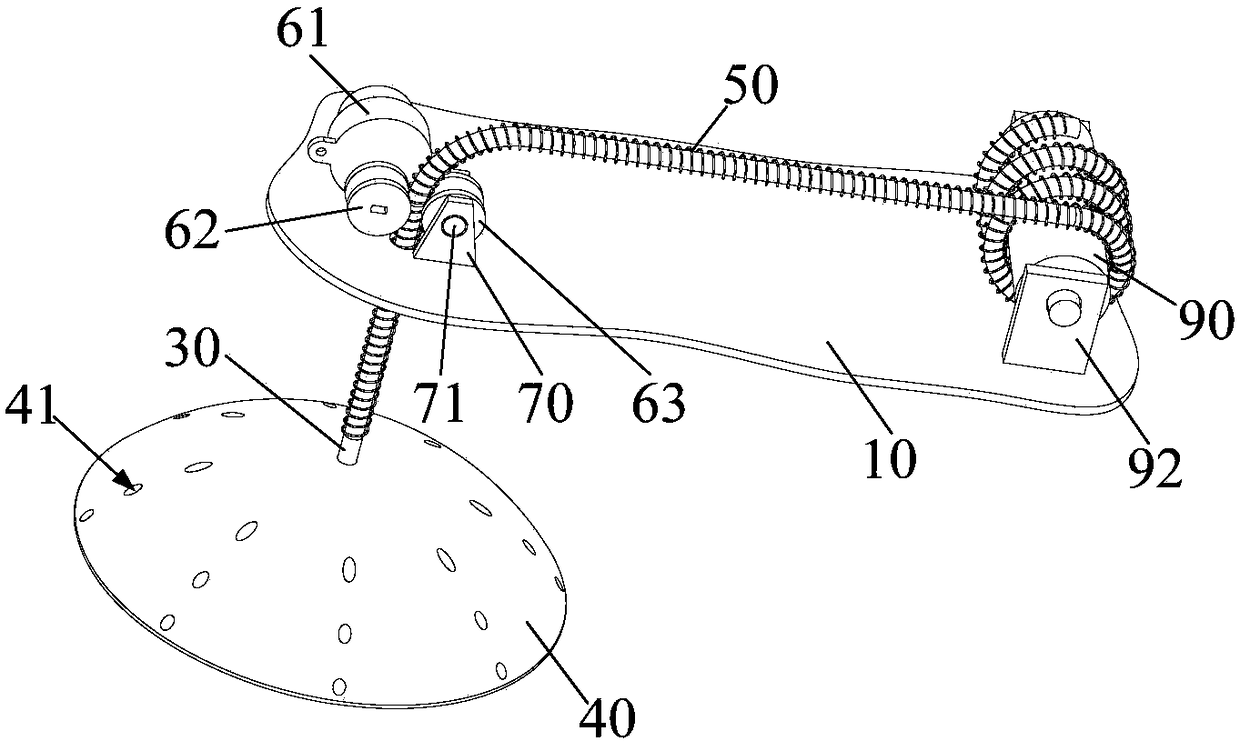

[0086] Embodiment one (as Figure 1 to Figure 5 shown)

[0087] The air intake pipe is a telescopic hollow hose 30, the input end of the air intake pipe is fixed on the upper cover 10, the output end of the air intake pipe runs through the upper cover 10 and communicates with the inner pot 20, and can move to the inner pot under the drive of the telescopic device. The bottom of the pot 20 conveys the air flow.

[0088] The intake pipe is a telescopic hollow hose 30, that is, the intake pipe can undergo axial telescopic deformation to adjust its length, and can undergo radial elastic deformation to adjust its cross-sectional size. In this way, the input end of the intake pipe is fixed. On the upper cover 10, it can ensure its stable cooperation with the air sources such as high-pressure air pumps and fans, and its output end can move up and down in the inner pot 20 under the drive of the telescopic device to ensure the use requirements.

[0089] Further, as Figure 1 to Figu...

Embodiment 2

[0109] The difference from Embodiment 1 is that: the groove wall of the wheel groove 64 is provided with an engaging groove 65 that is compatible with the spring wire of the spring tube 50, such as Figure 9 and Figure 13 As shown, the spring wire is embedded in the engaging groove 65 to engage the spring tube 50 with the groove wall of the wheel groove 64 .

[0110] Directly on the groove wall of the wheel groove 64, an engaging groove 65 that is compatible with the spring wire of the spring tube 50 is provided, then the spring wire can be directly embedded in the engaging groove 65, and then tightly engaged with the groove wall of the wheel groove 64, thereby improving the The occlusion depth further improves the reliability of cooperation between the spring tube 50 and the driving assembly 60 . Of course, in this case, the driving wheel 62 and the driven wheel 63 can also be soft rubber wheels.

[0111] Its working principle is the same as that of Embodiment 1, and will ...

Embodiment 3

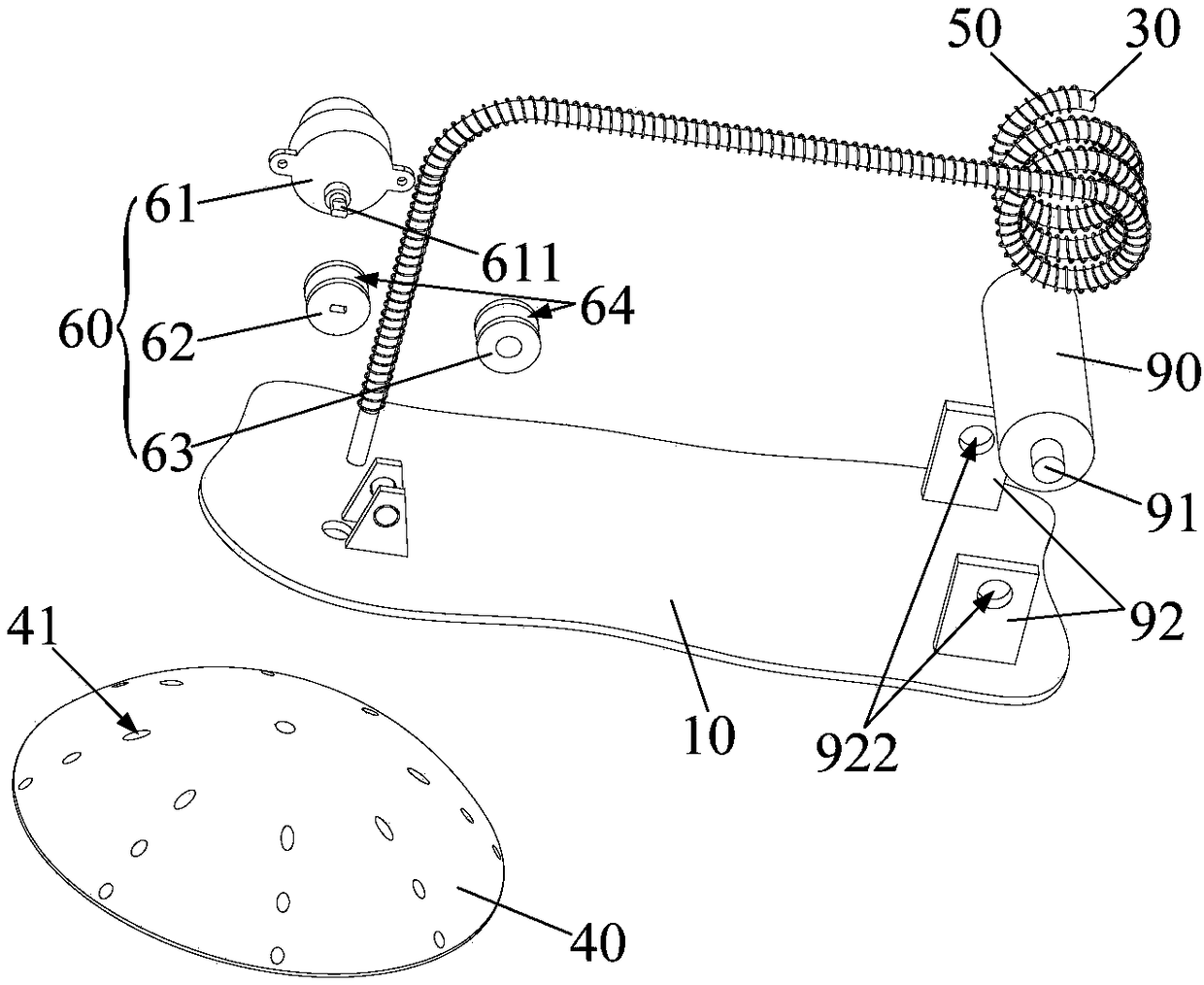

[0112] Embodiment three (as Figure 6 to Figure 17 shown)

[0113] On the basis of the second embodiment, further, a sliding hole 72 is opened on the bracket 70, and the wheel shaft 71 is inserted in the sliding hole 72, and can slide back and forth along the sliding hole 72, as Figure 6 to Figure 8 Shown; The floating limit assembly 80 that abuts against the axle 71 is also installed on the bracket 70, as Figure 6 , Figure 7 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, the floating limit assembly 80 can perform telescopic movement, so that the wheel shaft 71 slides along the sliding hole 72 to adjust the size of the gap, so that the spring tube 50 and the driving wheel 62 are tightly engaged.

[0114] Since the spring tube 50 and the hollow hose 30 are also accompanied by an appropriate amount of change in cross-sectional size when doing telescopic movement, if the gap between the driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com