Liquid crystal optical switch for optical phased array scanning

An optical phased array and optical switch technology, applied in the field of optical phased arrays, can solve the problems of inability to electronically control scanning and depth focusing control, and inability to use beam phase modulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

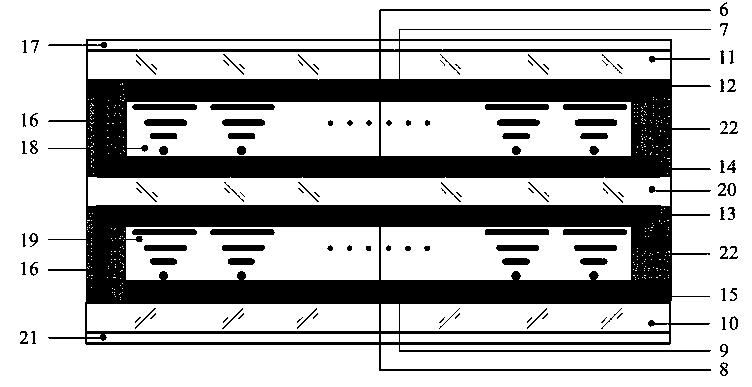

[0031] Such as figure 1 , 2 , 3 and 4, the present invention is composed of a first layer of liquid crystal panel 18 and a second layer of liquid crystal panel 19 arranged up and down, and the first layer of liquid crystal panel 18 is successively provided with row first orientation film 7, Row scanning electrode 12, upper layer glass plate 11 and upper polarizing plate 17, the second alignment film 6, row signal electrode 14 and middle glass plate 20 are arranged in parallel successively below the first layer liquid crystal plate 18; The second layer liquid crystal plate 19 The third alignment film 8 and the column scanning electrode 13 are arranged in parallel on the top, and the fourth alignment film 9, the column signal electrode 15, the lower glass plate 10 and the lower polarizer 21 are arranged in parallel on the bottom of the second layer of liquid crystal panel 19; The row signal electrodes 14 and the column signal electrodes 15 are respectively connected with electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com