Easy-to-plug waterproof fiber optic connector

An optical fiber connector, waterproof technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of bumps slipping out of grooves, loose, unable to become a whole, no self-locking protection, etc., to achieve firm connection and compact structure. , the effect of easy construction and towing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

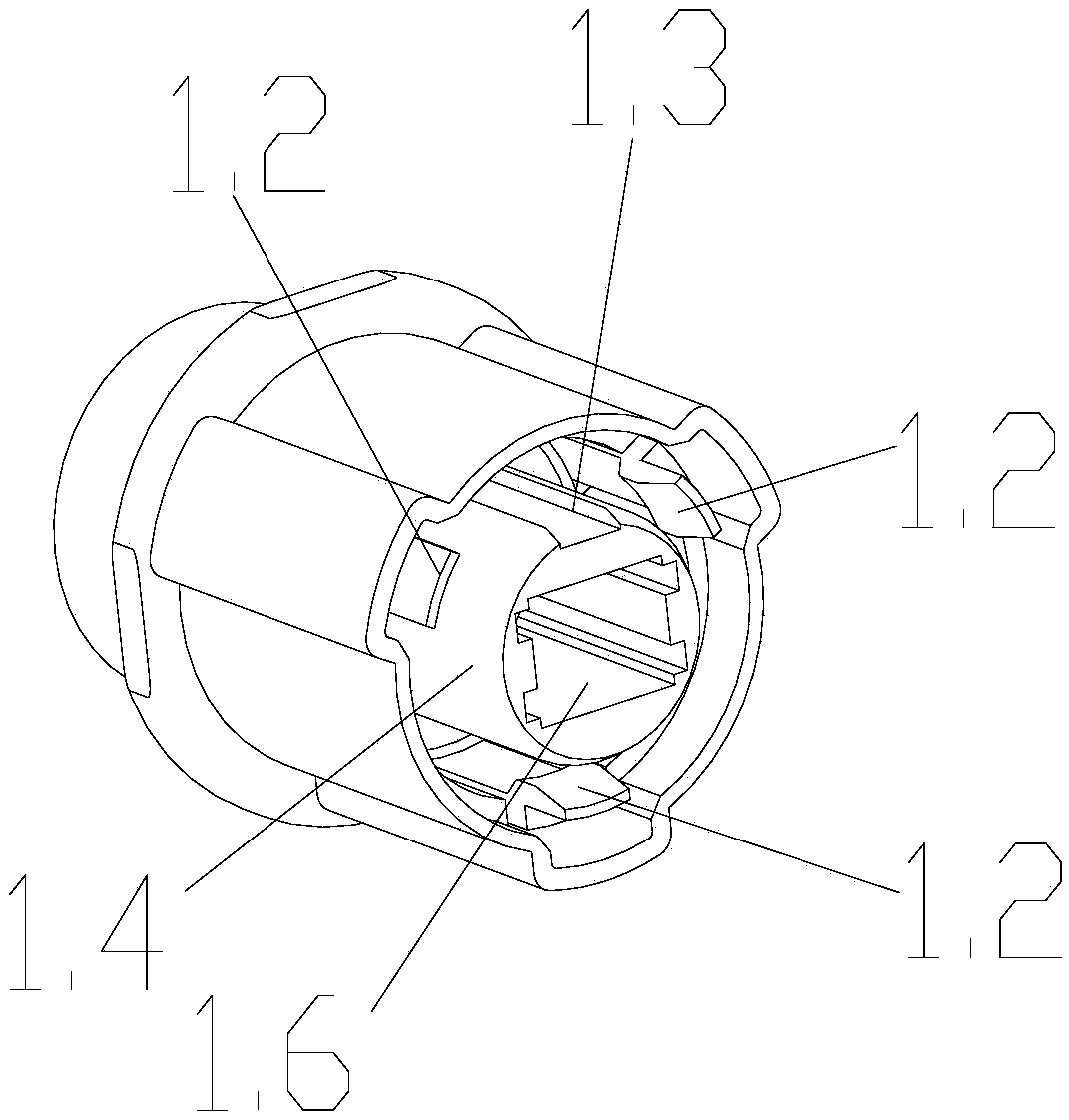

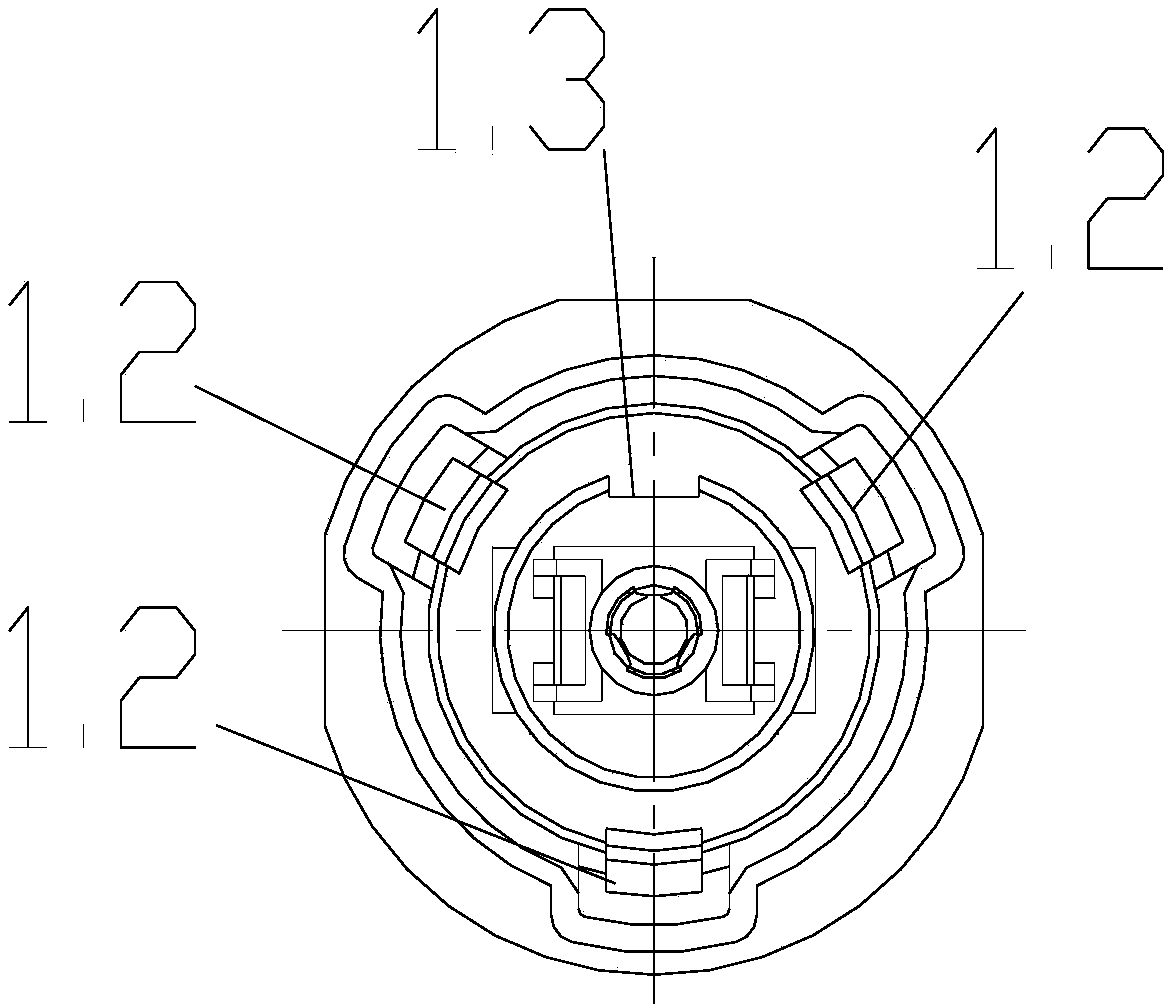

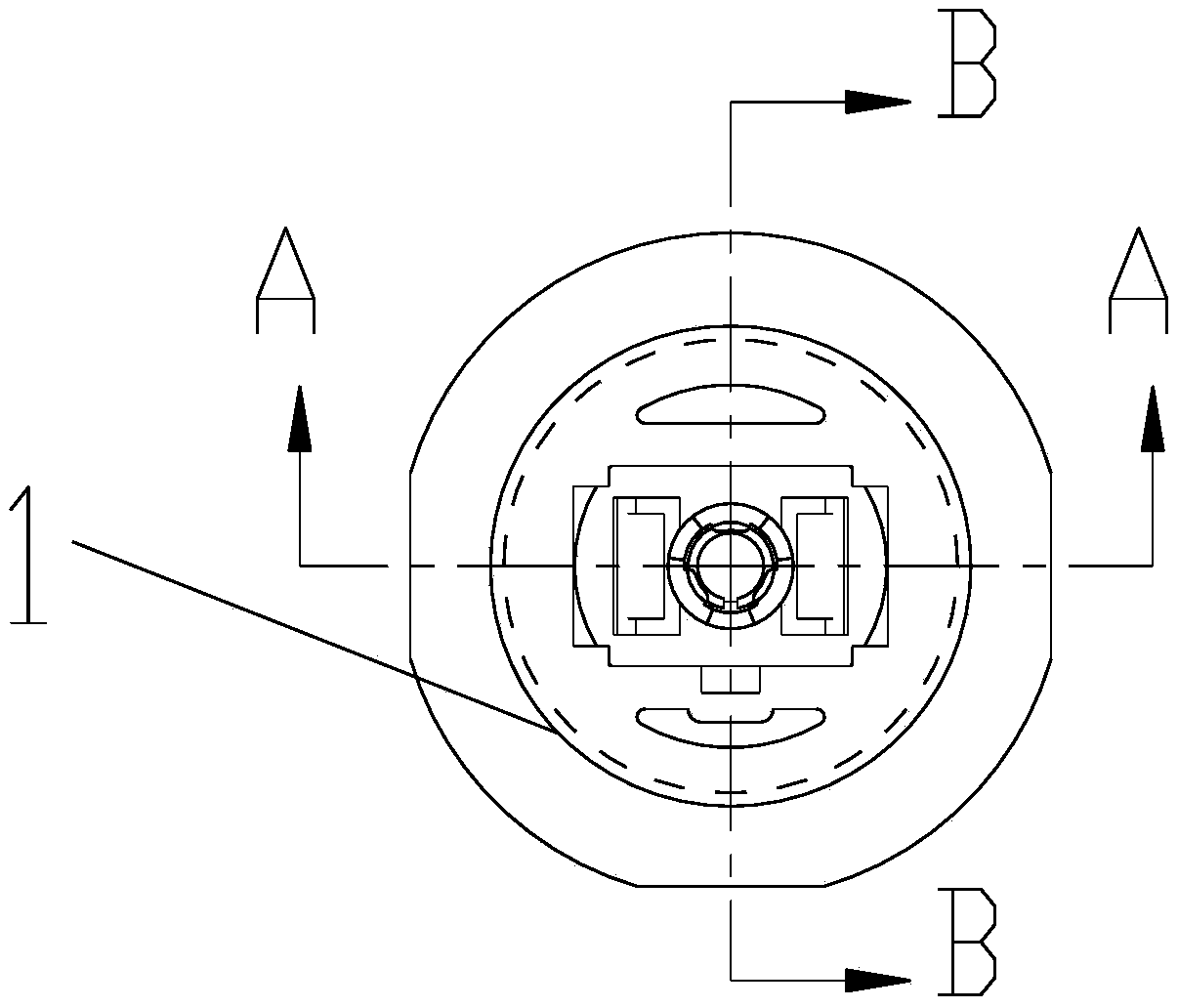

[0028] Including an adapter assembly and a connector assembly, the adapter assembly includes an adapter cylinder body 1, the adapter cylinder body is divided into a front chamber and a rear chamber, and the front chamber is provided with an inner sleeve 1.4, which is arranged between the inner sleeve and the inner wall of the adapter cylinder There are claws 1.2, and the rear cavity is provided with a hook 1.1. The claws include three axial claws distributed along the circumferential interval. The front ends of the axial claws are provided with inwardly protruding buckles. The rear end of the claw is fixedly connected with the adapter cylinder; a nest 1.5 is provided at the rear end of the inner hole of the inner tube, and the nest extends to the rear cavity, and a ceramic sleeve 2 is installed in the nest, and the adapter cylinder includes the front Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com