Method for testing high-cycle fatigue performance of engine fan blade

A technology of fan blades and testing methods, which is applied in the direction of engine testing, machine gear/transmission mechanism testing, and mechanical component testing, etc. Fully reflect the fatigue performance of fan blades and other issues, to achieve the effect of shortening the test time, improving reliability and increasing the test frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

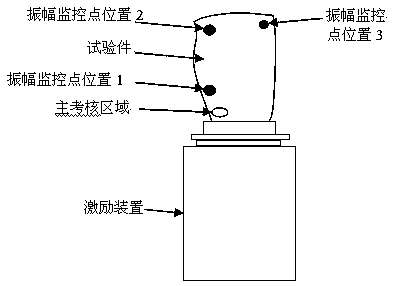

[0036] like Figure 1-10 As shown, a method for testing the high cycle fatigue performance of an engine fan blade comprises the following steps:

[0037] The first step is to design the fixture based on the geometric characteristics of the tenon of the engine fan blade, and rigidly fix the fan blade to the excitation device. The size is about 600mm, and the high rigidity fixture is designed and manufactured to fix the fan blades on the horizontal sliding table of the electromagnetic vibrating table;

[0038] In the second step, according to the natural frequency, vibration shape and stress distribution of the engine fan blade under the clamping condition of the software prediction test, according to the requirements of the fatigue performance assessment part and the stress distribution law obtained by calculation, the excitation frequency, vibration shape and stress distribution of the loading equipment are initially selected. The position of the amplitude monitoring point, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com