Hole sealing method based on non-Newtonian fluid material with dilatancy

A non-Newtonian fluid and hole sealing technology, which is applied in the fields of discharge machinery, earthwork drilling, blasting, etc., can solve the problems of blasting rejection treatment of blastholes, the difficulty of sealing materials, and difficult handling of blasting rejection, and achieve innovation Anti-explosion treatment process, high energy utilization rate of explosives, and convenient recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

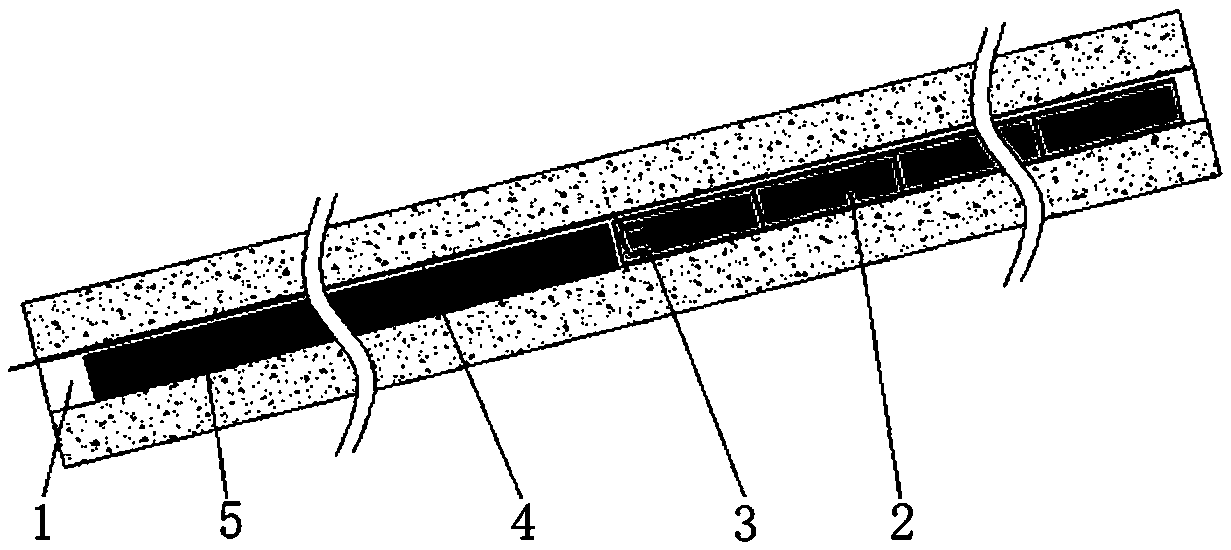

[0024] Taking the underground deep hole blasting in coal mine as an example, a 45m deep non-full-length charge drilling and blasting operation is carried out, and the present invention will be further described in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the blast hole depth is 45m, the drill hole diameter is 75mm, the expansion plastic sealing material roll diameter is 70mm, the explosive roll diameter is 60mm, the charge length is 24m, and the sealing section is 15m. The packaging bag of the expansion-plastic sealing material has certain flexibility and plasticity. When the sealing material in the hole is in a static liquid state, the flexible plastic packaging bag can expand to fill the hole wall space of the sealing section. Coal and rock blasting is carried out by using third-level aqueous explosives permitted in coal mines. Specific steps:

[0026] 1) Drilling hole 1 is completed, and after cleaning the hole, use explosives instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com