Combined refractory brick for easy connection and high temperature resistance

A technology of refractory bricks and high temperature resistance, which is applied in the field of refractory materials and can solve the problems of poor stability of refractory bricks and poor high temperature resistance of refractory bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

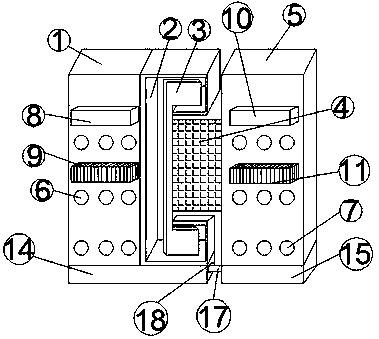

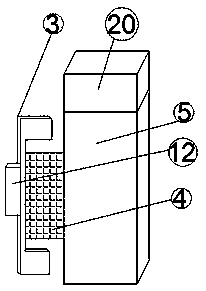

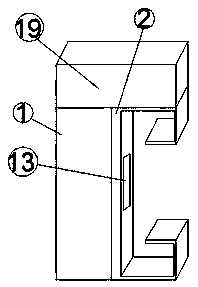

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

[0031] see Figure 1-5 , a combined refractory brick that is convenient for connection and high temperature resistance, including a first refractory brick body 1, one side of the first refractory brick body 1 is connected to a grooved stone 2, and the inner groove of the grooved stone 2 is set Some matching first stone slabs 3, one side of the first stone slab 3 is provided with a fixed connection fixing plate 4, one side of the fixing plate 4 is fixedly connected to the second refractory brick body 5, and the first refractory brick The body 1 is provided with several groups of first circular through holes 6, the second refractory brick body 5 is provided with several groups of second circular through holes 7, and the inside of the first refractory brick body 1 is provided with first air Gel filling layer 8, the first refractory brick body 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com