Handheld dry ice filling device

A filler and hand-held technology, which is applied in the field of hand-held dry ice fillers, can solve the problems of low automation, large volume and high cost of solid-state ice machines, and achieve the goal of improving efficiency, improving dry ice conversion rate, and simplifying cumbersome steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

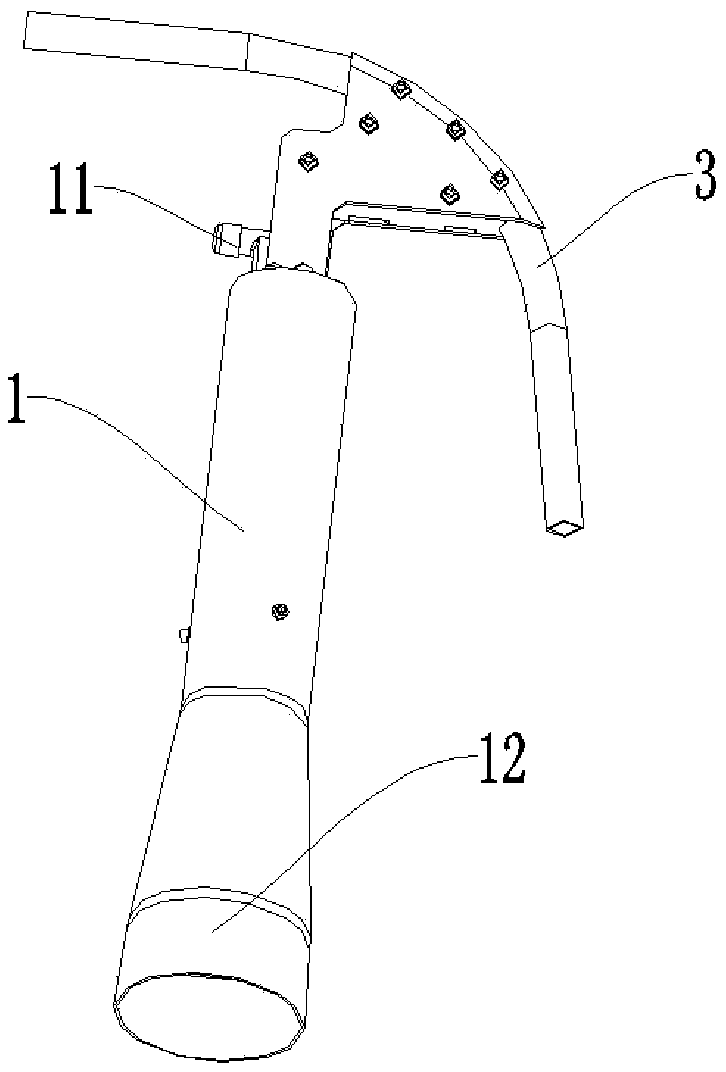

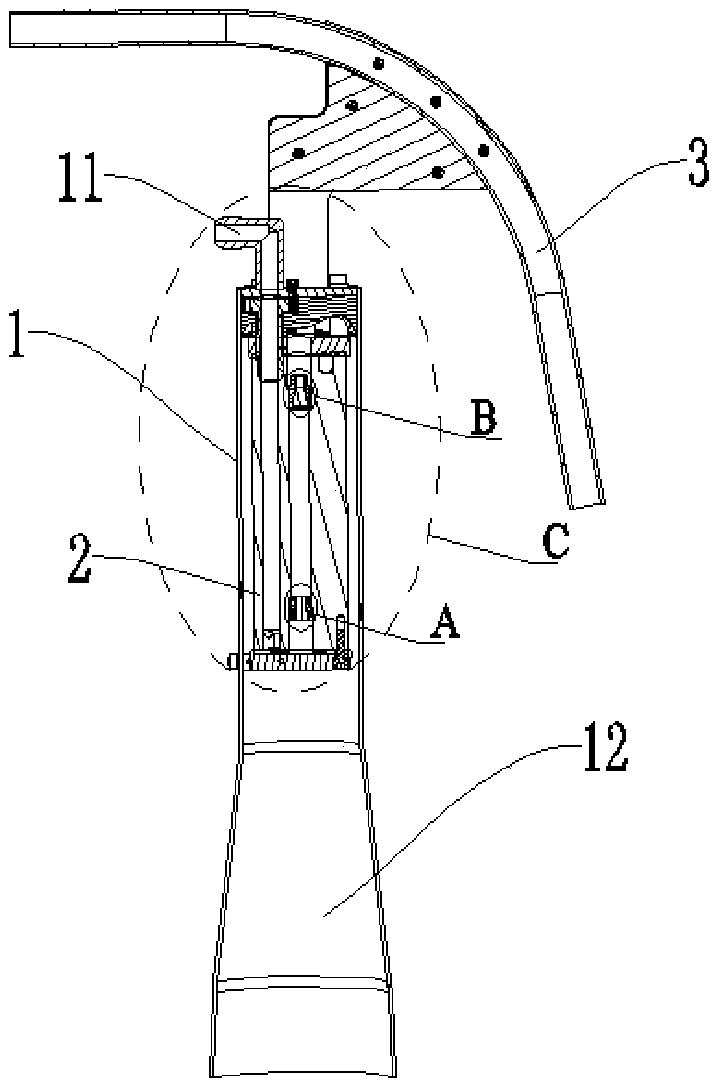

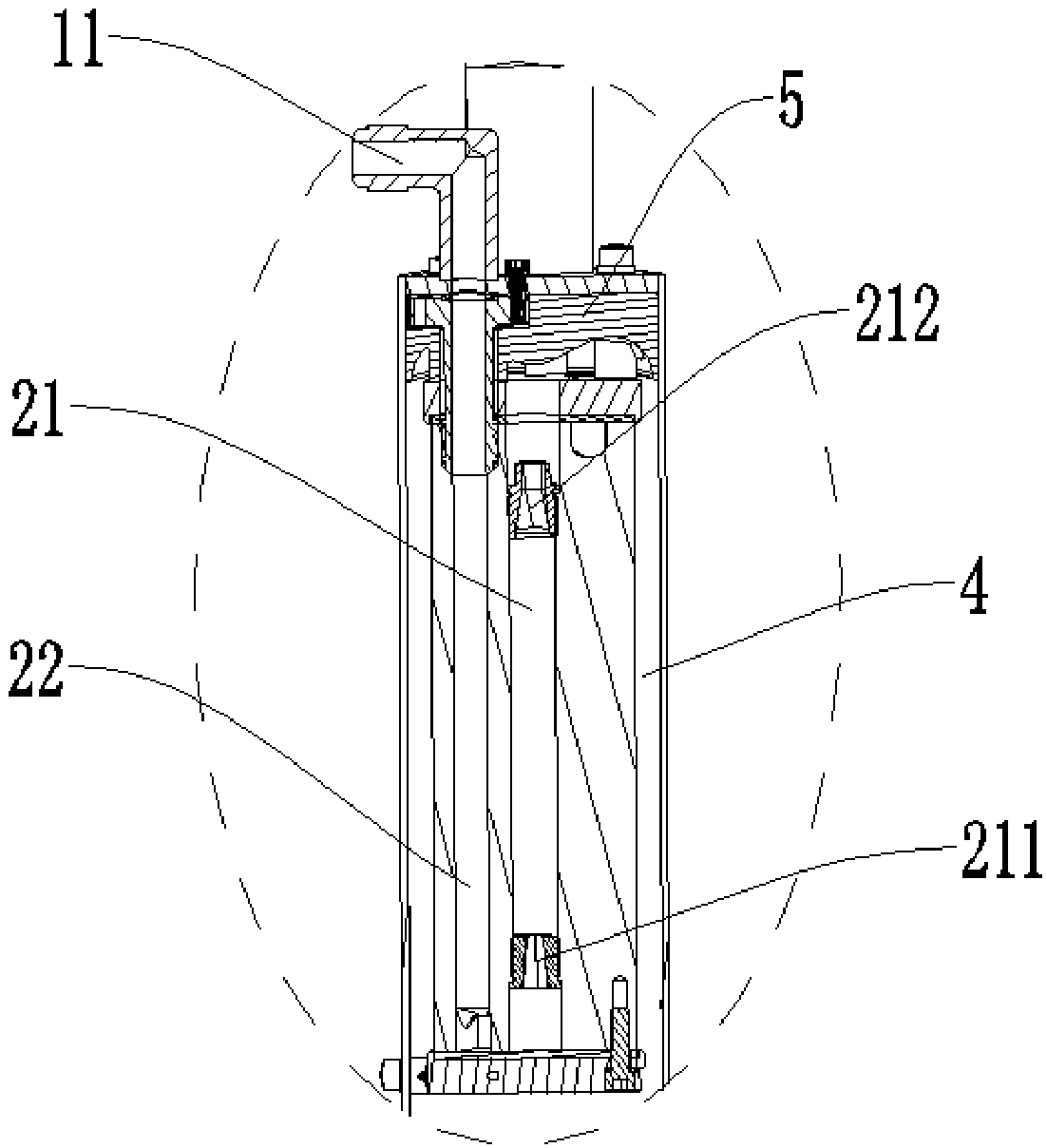

[0035] Embodiment 1, with reference to figure 1 , 2 As shown, the present invention provides a hand-held dry ice filler, comprising: a filling bucket 1 , a heat exchanger 2 disposed in the filling bucket 1 and a handle 3 fixedly connected to the filling bucket 1 .

[0036] optional, see figure 1 , 2 As shown, the heat exchanger 2 is fixedly connected to the filling barrel 1 by fastening bolts. The handle 3 has a support rod extending axially and radially along the filling barrel 1, which is convenient for the user to lift and hold. The support rod is fixed to the filling bucket 1 through a support plate. Optionally, the support plate is welded to the filling bucket 1 . The support plate has an arc-shaped arm, and the axially and radially extending support rods are respectively arranged at two ends of the arc-shaped arm.

[0037] The filling barrel 1 is provided with a liquid inlet pipe 11 and a spray port 12, and the liquid inlet pipe 11 is used for connecting high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com