A kind of chlorella and its application in biogas slurry purification

A chlorella and biogas slurry technology, applied in the field of microorganisms, can solve the problems of eutrophication, high energy consumption, and difficulty in absorbing biogas slurry on site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Separation and purification of algal strains

[0035] (1) Sample collection

[0036] The algal strains involved in the present invention are obtained by sampling and separating from the soil polluted by pig manure anaerobic digestion biogas slurry in the biogas service station of Xibaidian Village, Daxingzhuang Town, Pinggu District, Beijing. Soil samples were collected from the soil surface at selected locations, placed in sealed bags, and stored in a 4°C refrigerator for later use.

[0037] (2) Separation, purification and cultivation of algae strains

[0038]Take about 0.5 g of soil sample in a 24-well tissue culture dish, add BG11 liquid medium (the specific composition of BG11 medium is shown in Table 1) and place it in a light incubator with adjustable environmental parameters for algae enrichment culture. After culturing for 3-4 days, the color of the medium can be clearly seen to change from colorless to light green. Then on the BG11 solid plate...

Embodiment 2

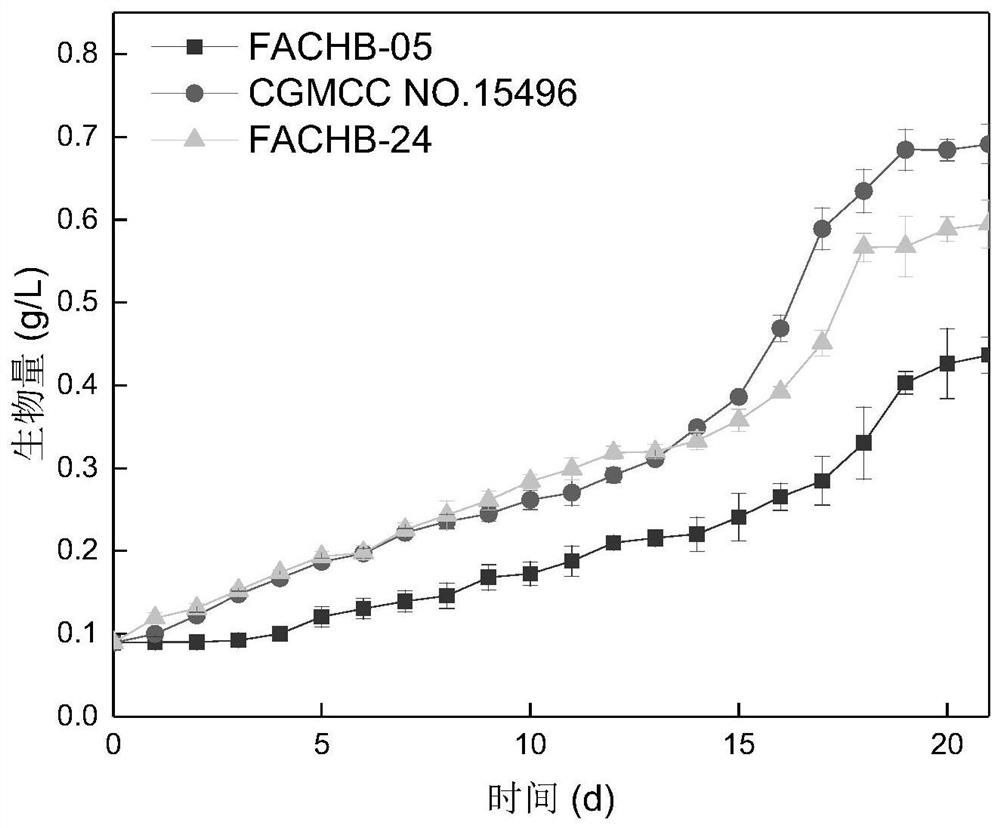

[0042] Embodiment 2 research on the optimum culture condition of algae strain

[0043] After obtaining the above-mentioned microalgae species with sufficient biomass, in order to explore its suitable culture conditions, the present invention carried out a single factor test on four common technical parameters of microalgae culture, light intensity, photoperiod, temperature and inoculum size—positive A series of optimization studies such as cross test-response surface test, the value range of each parameter is: light intensity: 50μmol / m 2 / s~250μmol / m 2 / s; Photoperiod: (12~20) / (4~12); Temperature: 20°C-30°C; Inoculation amount: 0.04~0.15g / L.

[0044] Finally, the most suitable culture condition for this strain of microalgae is that the light intensity is 140 μmol / m 2 / s, the photoperiod is 19:5 (light:dark), the temperature is 26±0.5°C, and the inoculum volume is 0.058g / L. The culture vessel used in this stage is a 250mL Erlenmeyer flask (effective culture volume is 150mL), ...

experiment example

[0045] Experimental example: identification and preservation of algae strains

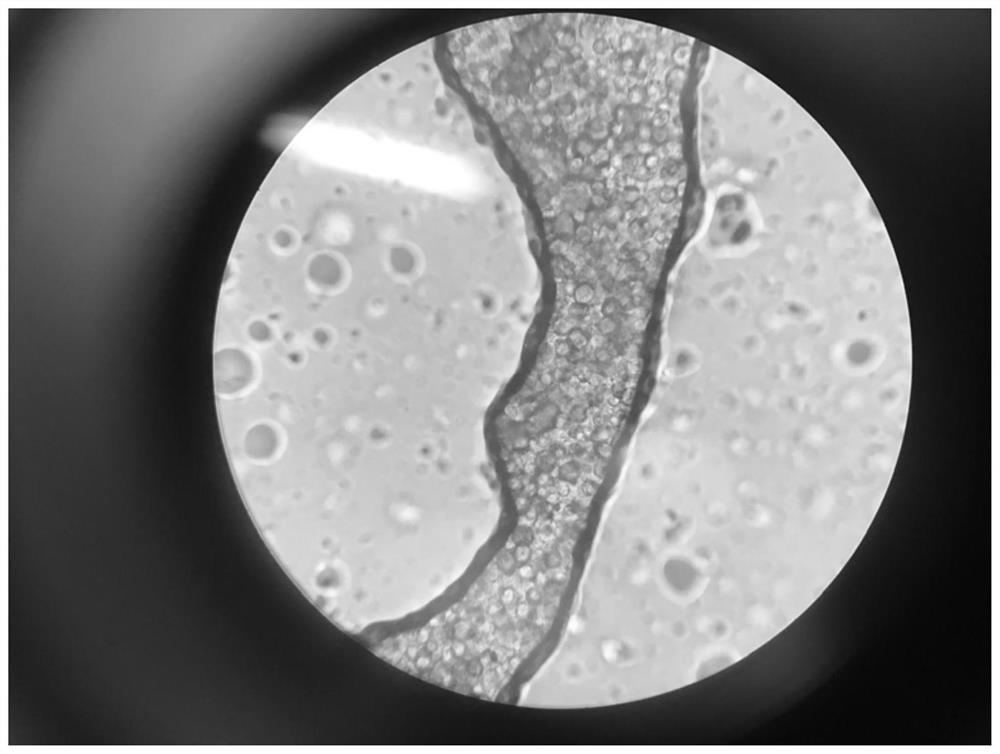

[0046] The identification of the algae strains was carried out in two steps, firstly the preliminary morphological observation, and then the molecular biological identification. The isolated and purified microalgae strains were observed and photographed using an optical microscope (10x eyepiece × 40x objective). Observe the cell shape, size, structure and other characteristics of the algae strain. The morphology of algal strains observed under the optical microscope is as follows: figure 1 shown.

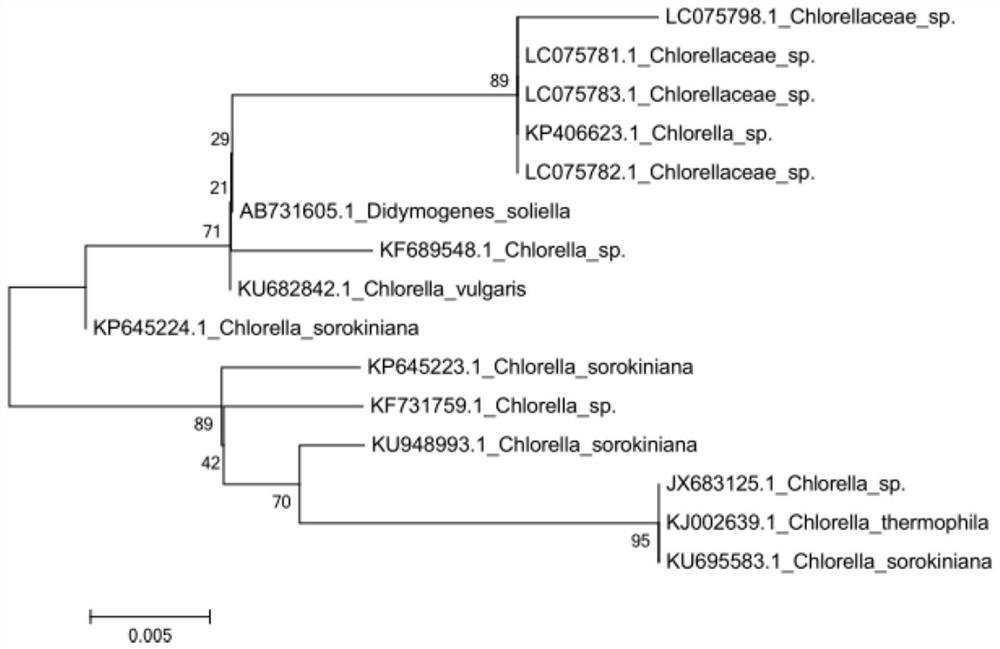

[0047] The strain of microalgae obtained by separation and purification of the present invention is observed under a microscope, and the algae body is green, and it is a single-cell population, and the cells are oval. Molecular biological identification of algae strains was carried out, using DNAMAN and Primer 5.0 software to design primers using the extracted DNA as a template (primer sequence forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com