A kind of self-cleaning nano heat insulation coating based on cesium tungsten bronze and its preparation method

A cesium tungsten bronze and nano heat insulation technology, applied in the field of coatings, can solve the problems of injury to construction workers and users, poor dispersion, etc., and achieve the effects of enhanced anti-fouling performance, low content, and no harm to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

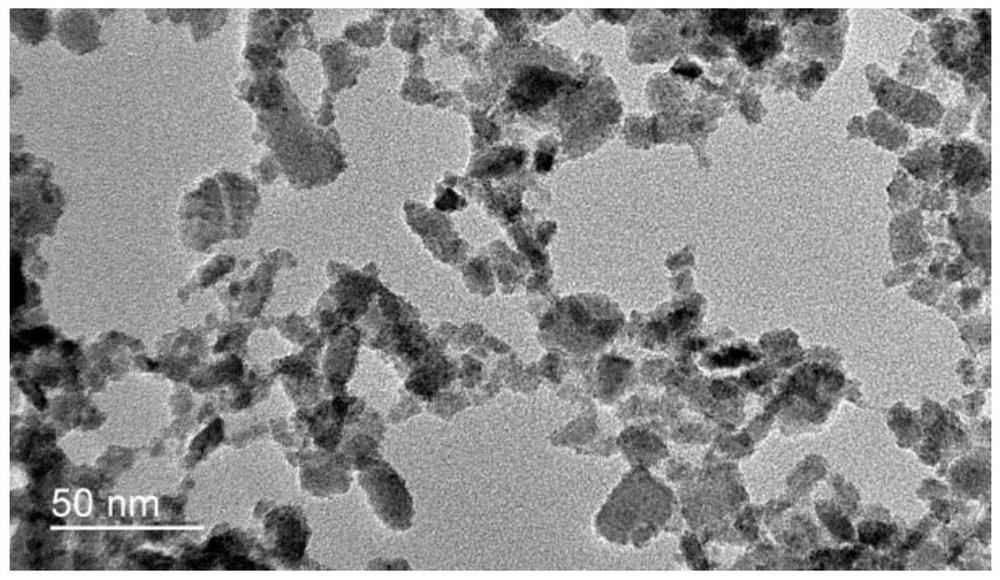

[0047] Take 10 mass parts of WCl 6 , 2 parts by mass of CsOH·5H 2 O, the acetic acid of 35 mass parts and the PVP of 15 mass parts, stir together, to obtain the first mixture; The first mixture is heated to 80 ℃, and insulation 2h; Then, the first mixture is continued to heat up to 220 ℃, and in React at this temperature for 20 hours, and then centrifuge and dry to obtain nano cesium tungsten bronze particles. Carry out XRD analysis to this nano cesium tungsten bronze particle, as figure 1 shown, and performed TEM analysis, as figure 2 As shown, it can be seen that its average diameter is 20 nm.

[0048] Take 10 parts by mass of TiCl 4 and 30 parts by mass of absolute ethanol, and mixed to obtain the second mixture; then the second mixture was reacted at 180°C for 8h, and processed by centrifugation and drying to obtain nano-TiO 2 particles. The TiO 2 Particles were subjected to XRD analysis, such as image 3 shown, and performed TEM analysis, as Figure 4 As shown, ...

no. 2 example

[0054] Get 13 mass parts of WCl 6 , 2 parts by mass of CsOH·5H 2 O, 40 parts by mass of acetic acid and 20 parts by mass of PVP were stirred together to obtain the first mixture; the first mixture was heated to 70°C and kept for 1.5h; then, the temperature of the first mixture was continued to rise to 220°C, and React at this temperature for 20 hours, and then centrifuge and dry to obtain nano cesium tungsten bronze particles.

[0055] Take 15 parts by mass of TiCl 4 and 40 parts by mass of absolute ethanol, and mixed to obtain the second mixture; then the second mixture was reacted at 180°C for 8h, and processed by centrifugation and drying to obtain nano-TiO 2 particles.

[0056] Get the nano cesium tungsten bronze particle of 50 mass parts, the nano TiO of 10 mass parts 2 Particles, 2 parts by mass of SN5040 coupling agent and 40 parts by mass of deionized water, and then ball milled together to obtain cesium tungsten bronze / TiO 2 Composite particle aqueous slurry, and...

no. 3 example

[0059] Take 15 mass parts of WCl 6 , 4 parts by mass of CsOH·5H 2 O, the acetic acid of 30 mass parts and the PVP of 15 mass parts, stir together, to obtain the first mixture; The first mixture is heated to 70 ℃, and insulation 1h; Then, the first mixture is continued to heat up to 240 ℃, and in React at this temperature for 30 hours, and then centrifuge and dry to obtain nano cesium tungsten bronze particles.

[0060] Get 12 parts by mass of TiCl 4 and 30 parts by mass of absolute ethanol, and mixed to obtain the second mixture; then the second mixture was reacted at 180°C for 8h, and processed by centrifugation and drying to obtain nano-TiO 2 particles.

[0061] Get the nano cesium tungsten bronze particle of 45 mass parts, the nano TiO of 8 mass parts 2 Particles, 2 parts by mass of SN5040 coupling agent and 50 parts by mass of deionized water, and then ball milled together to obtain cesium tungsten bronze / TiO 2 Composite particle aqueous slurry, and the cesium tungste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com