Waterborne copolyester and preparation method thereof

A copolyester, water-based technology, applied in the field of water-based copolyester and its preparation, to achieve the effect of improving optical transmittance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

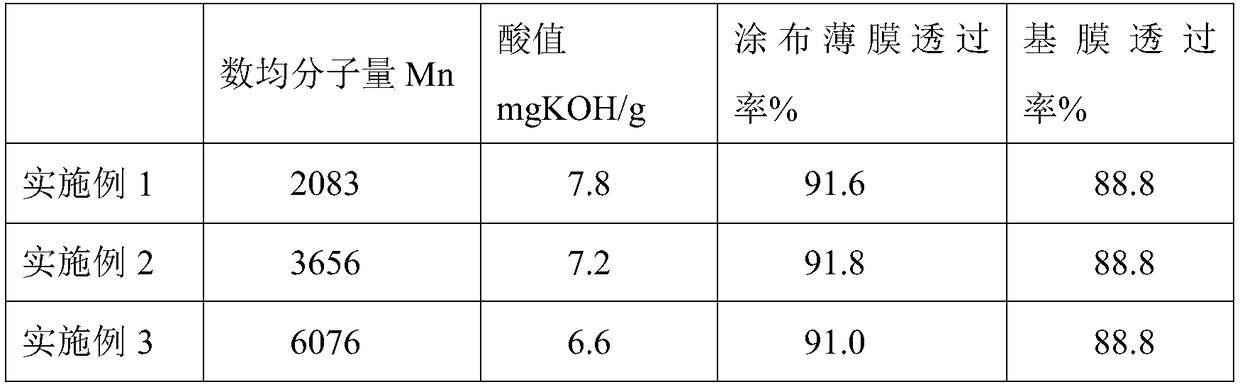

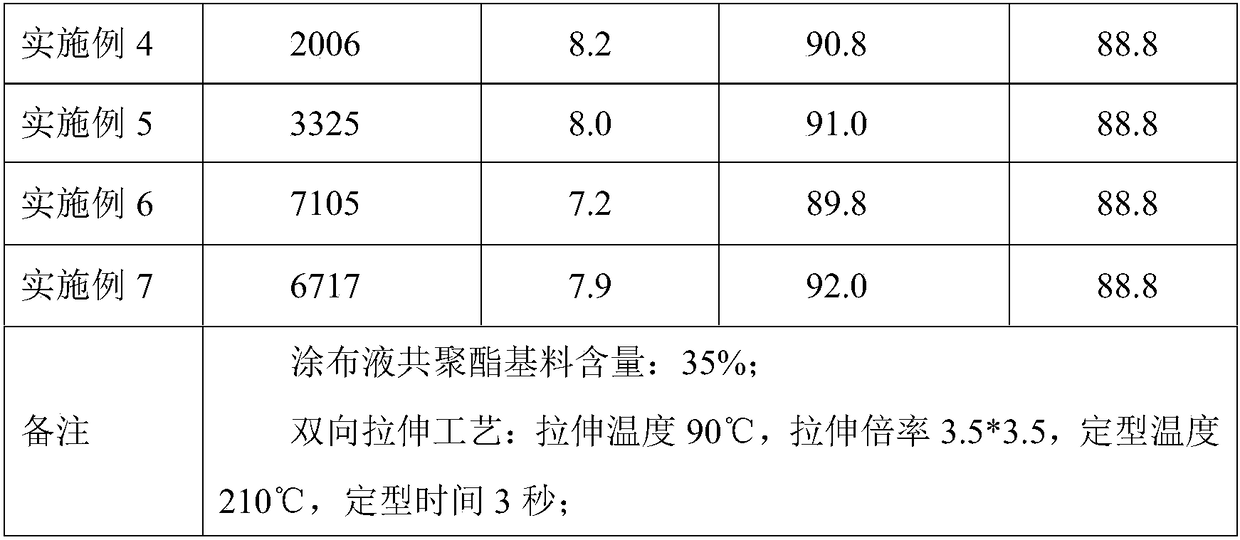

Examples

Embodiment 1

[0044] Example 1: In a 20-liter polymerization reactor, PTA, IPA, AA, EG, and NPG were added according to the alkyd molar ratio of 1.5:1.0. Among them, the ratio of PTA to the total moles of dibasic acids is 40%, the ratio of IPA to the total moles of dibasic acids is 40%, the ratio of AA to the total moles of dibasic acids is 20%; the ratio of EG to the total moles of dibasic alcohols 75%, NPG accounted for 25% of the total glycol mole ratio, added antimony ethylene glycol 1.00 grams, phosphoric acid 1.50 grams, 2.05 grams of sodium acetate. use N 2 Pressurize after replacement three times, use the valve at the top of the fractionation column to adjust the pressure in the kettle at 0.2-0.25MPa (gauge pressure), and raise the temperature to 195°C-245°C to carry out the esterification reaction. When the amount of esterified water reaches the theoretical amount, release it to normal pressure, add 300 grams of SIPM powder, stir for 30 minutes, turn on the vacuum system, maintain...

Embodiment 2

[0045] Example 2: In a 20-liter polymerization reactor, PTA, IPA, AA, EG, and NPG were added according to the alkyd molar ratio of 1.5:1.0. Among them, the ratio of PTA to the total moles of dibasic acids is 50%, the ratio of IPA to the total moles of dibasic acids is 40%, the ratio of AA to the total moles of dibasic acids is 10%; the ratio of EG to the total moles of dibasic alcohols 60%, NPG accounted for 40% of the total molar ratio of glycols, 2.00 grams of ethylene glycol antimony, 2.75 grams of triphenyl phosphate, and 0.41 grams of sodium acetate were added. After the esterification was completed, 1000 grams of SIPE-EG solution with a mass fraction of 35% was added. The process control of esterification process, polycondensation process and preparation process is consistent with embodiment 1.

Embodiment 3

[0046] Example 3: In a 20-liter polymerization reactor, PTA, IPA, AA, EG, and NPG were added according to the alkyd molar ratio of 1.5:1.0. Among them, the ratio of PTA to the total moles of dibasic acids is 60%, the ratio of IPA to the total moles of dibasic acids is 25%, the ratio of AA to the total moles of dibasic acids is 15%; the ratio of EG to the total moles of dibasic alcohols 70%, NPG accounts for 30% of the total moles of glycols, 1.56 grams of ethylene glycol antimony, 3.00 grams of trimethyl phosphate, and 0.82 grams of sodium acetate are added. After the esterification is completed, 1200 grams of SIPE-EG solution with a mass fraction of 35% can be added. The process control of esterification process, polycondensation process and preparation process is consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com