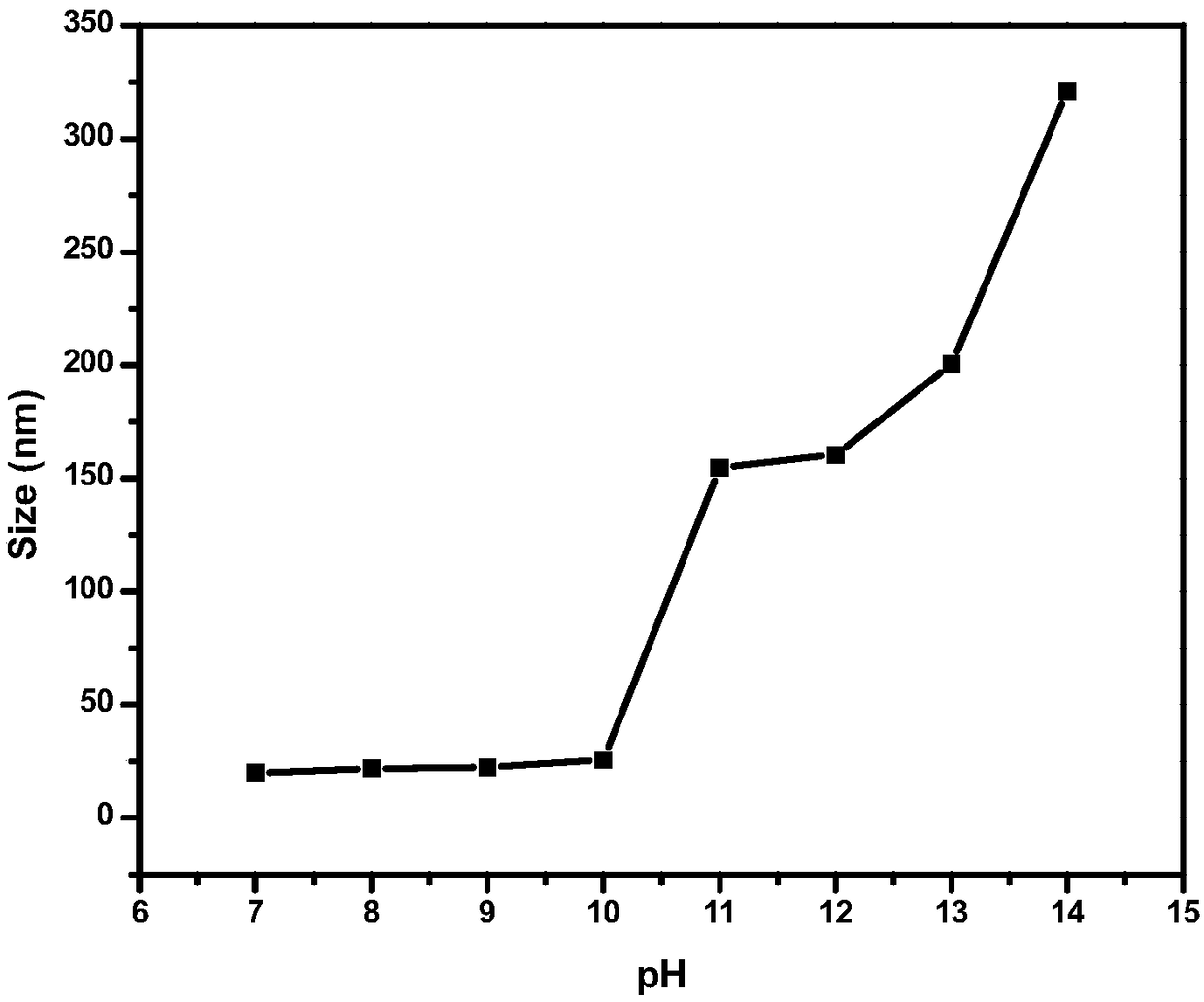

Method for preparing pH-responsive comb-structure polycarboxylic acid through terminal group functionalization

A technology with comb-like structure and end-group functions, which is applied in the field of pH-responsive polycarboxylic acid materials, can solve problems that have not been reported before, and achieve the effects of reducing capillary pressure, inhibiting shrinkage cracking, and increasing contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, 360g of tetrahydrofuran was added to the reactor, the temperature was raised to 120°C, 1.72g of di-tert-butyl peroxide was added and stirred for 10 minutes until it was evenly mixed, then 30g of N,N-diethyl-2-acrylamide and 11.06 g2-mercaptoethanol mixed solution for 1 hour, after the dropwise addition, continue to react at a constant temperature of 120°C for 1 hour to obtain a self-polymerized product poly N,N-diethyl-2-acrylamide solution; 10.71g allyl chloride, 217.14 Add gN,N-diisopropylethylamine and 0.72g tetraethylammonium iodide to the self-polymerization product solution in turn, stir and adjust the temperature to 120°C, react at a constant temperature of 120°C for 2 hours, and then distill under reduced pressure to remove tetrahydrofuran and Excessive reagent, obtain unsaturated poly N,N-diethyl-2-acrylamide macromonomer; 46.66g unsaturated poly N,N-diethyl-2-acrylamide macromonomer is dissolved in In 56.10g of solvent water, heat up to 90°C, stir for 1...

Embodiment 2

[0036] First, 270g of dimethyl sulfoxide was added to the reactor, the temperature was raised to 110°C, 5.54g of tert-butyl peroxybenzoate was added and stirred for 12 minutes until it was evenly mixed, then 30g of 4-vinylpyridine and 11.15g of 2- The mixed solution of mercaptoethanol was added for 3 hours. After the dropwise addition, the reaction was continued at a constant temperature of 110°C for 2 hours to obtain a self-polymerized product poly-4-vinylpyridine solution; , N-diisopropylethylamine and 1.35g tetrabutylammonium bromide were added to the self-polymerization product solution in turn, stirred and adjusted to 110°C, reacted at a constant temperature of 110°C for 4 hours, and then distilled off dimethyl under reduced pressure sulfoxide and excess reagent to obtain unsaturated poly-4-vinylpyridine macromonomer; 50.68g unsaturated poly-4-vinylpyridine macromonomer was dissolved in 50.68g solvent water, heated to 85°C, stirred Wait for 12 minutes to mix it evenly, th...

Embodiment 3

[0038] First, 150g of aniline was added to the reactor, the temperature was raised to 90°C, 5.10g of dibenzoyl peroxide was added and stirred for 20 minutes until it was evenly mixed, then 30g of diethylaminoethyl methacrylate and 2.98g of 3-mercapto Mixed solution of propanol for 8 hours, continue to react at a constant temperature of 90° C. for 4 hours after the dropwise addition, to obtain a self-polymerized product polydiethylaminoethyl methacrylate solution; Add methylethylenediamine and 0.27g benzyltriethylammonium chloride to the self-polymerization product solution in turn, stir and adjust the temperature to 70°C, react at a constant temperature of 70°C for 9 hours, and then distill under reduced pressure to remove aniline and excess reagents. Obtain unsaturated polydiethylaminoethyl methacrylate macromonomer; 34.61g unsaturated polydiethylaminoethyl methacrylate macromonomer is dissolved in 27.68g solvent water, be warmed up to 70 ℃, stir Wait for 20 minutes to mix it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com