Blanking tube induced air damping device

A technology of damping device and inducing wind, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of reducing the air flow of the induced coal pipe, and achieve a light rotating structure, small load on the tension arm and bearing, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

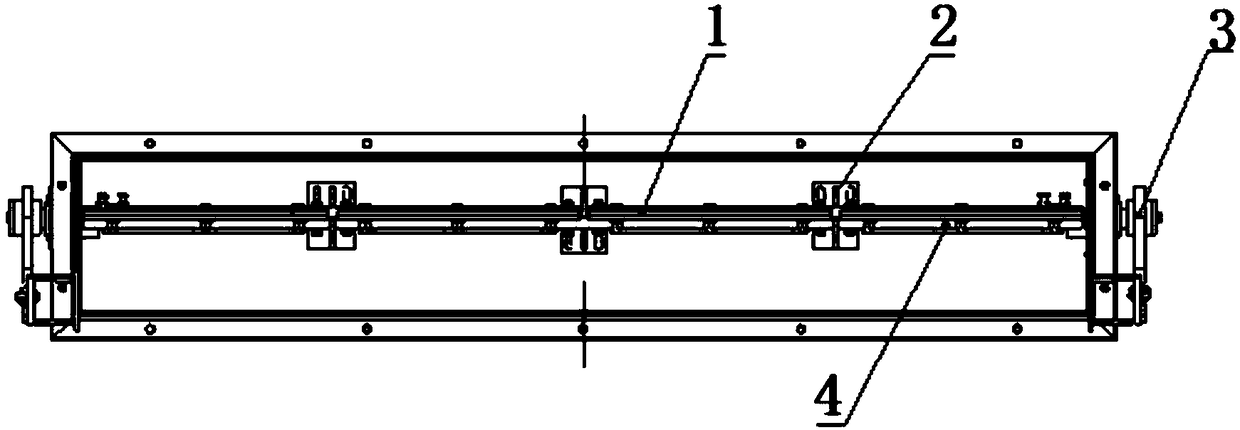

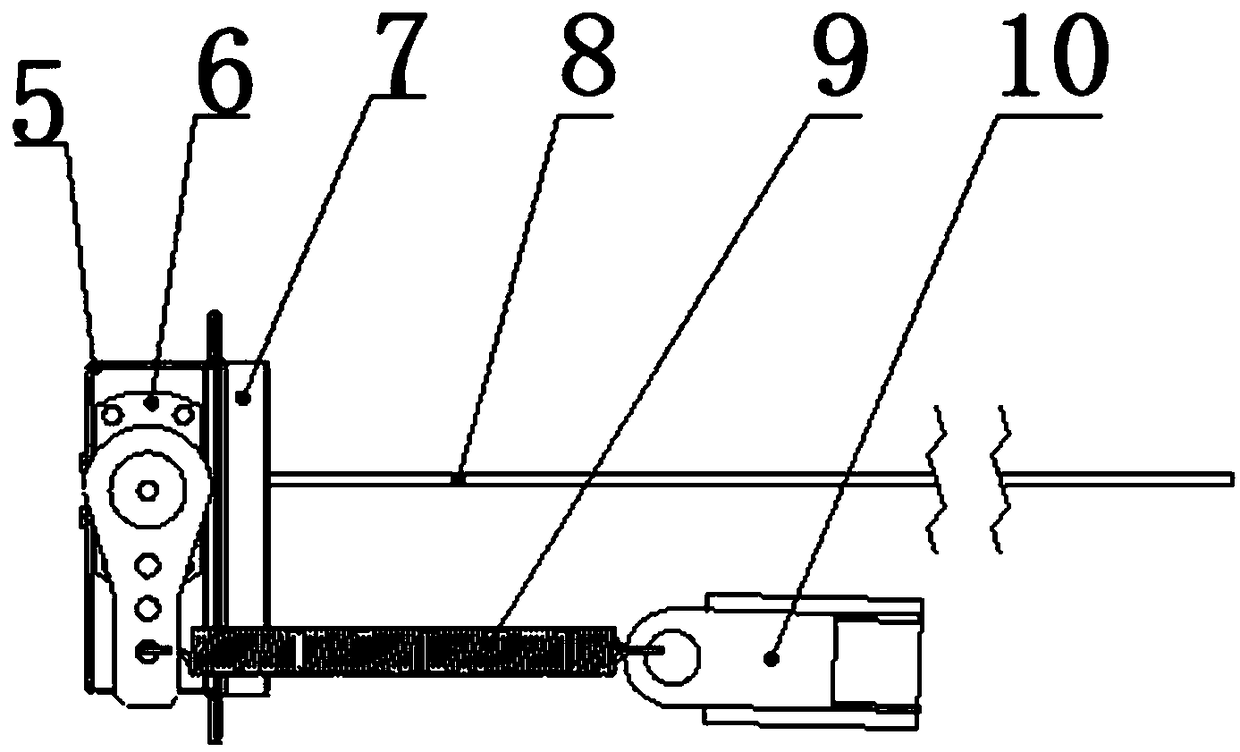

[0025] Such as Figure 1-2 As shown, a drop tube induced wind damping device includes a rotating structure 1, an outer casing 5 arranged on the periphery of the rotating structure 1 and two bearing seats 6 arranged on the outer casing 5, the two The bearing seat 6 is coaxially fixed at both ends of the outer casing 5, and the rotating structure 1 includes a detachable rotating shaft 4 and a choke plate 8 at both ends, and the choke plate 8 has a small gap with the side wall of the drop tube. The angle or close to parallel, relative to the horizontal plane choke plate 8 rotation angle will be greater than 60 degrees, the two ends of the rotating shaft 4 respectively pass through the bearing seat 6 and rotatably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com