Airport luggage conveying rack

A technology for conveying racks and luggage, which is applied to mechanical conveyors, conveyors, conveyor objects, etc., can solve the problems of large luggage conveying racks, serious surface friction, inconvenient processing, etc., and achieves stable operation, compact structure, and long and highly scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

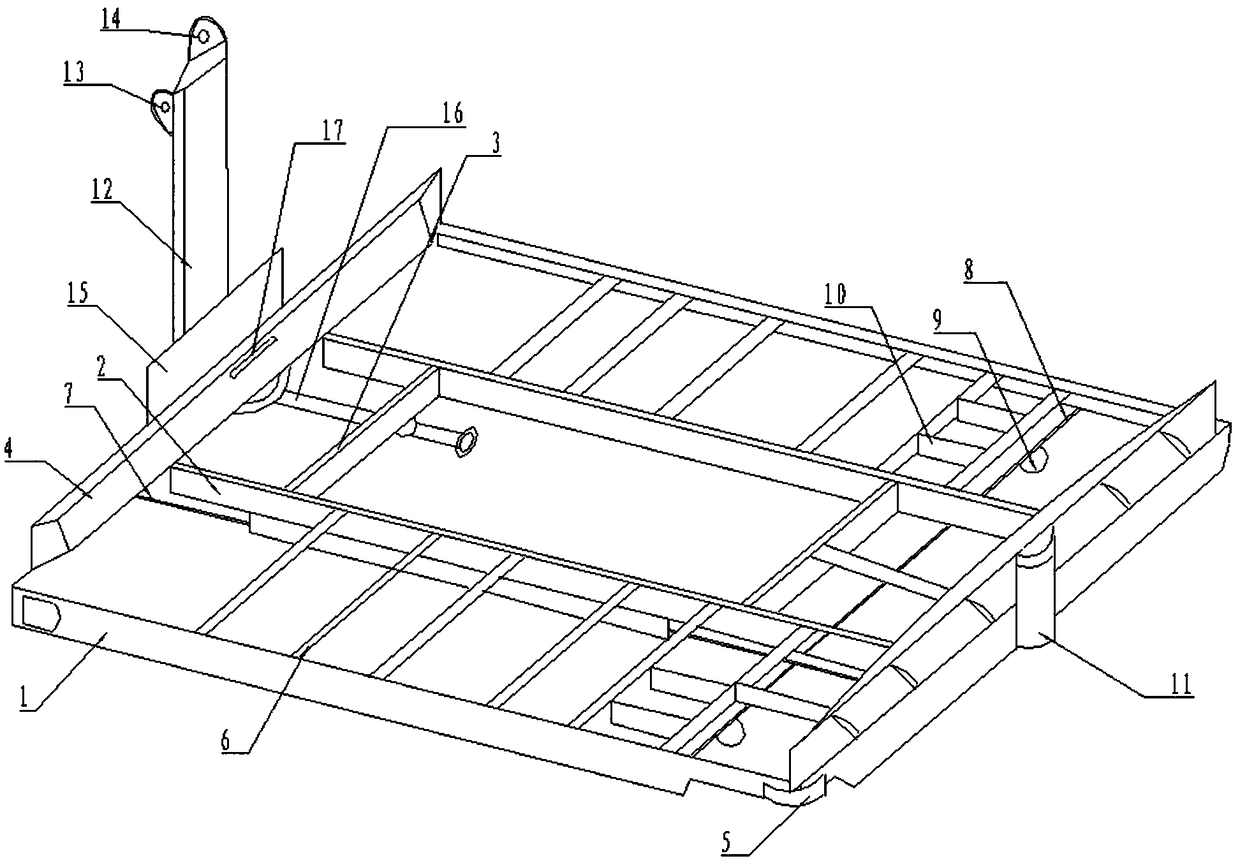

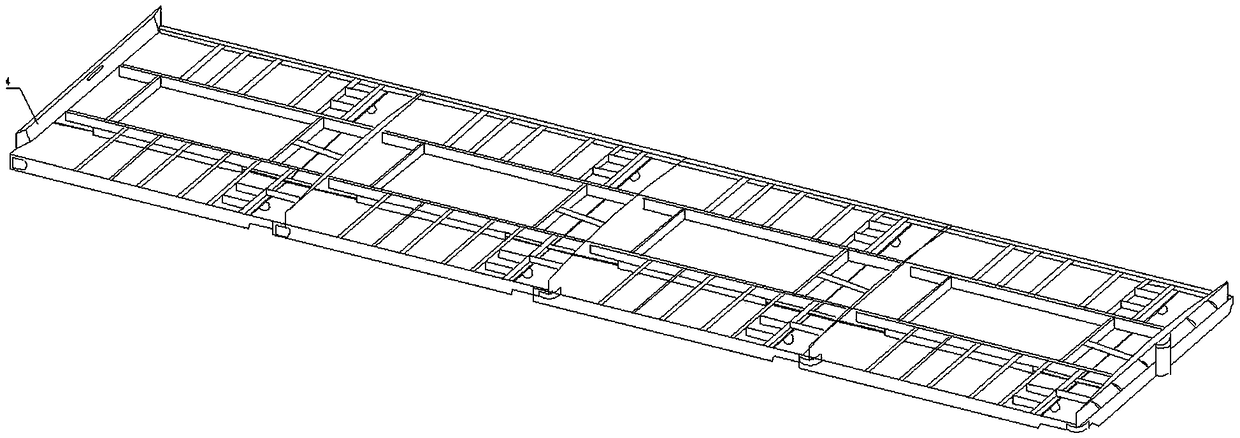

[0018] see figure 1 , figure 2 , the embodiment of the present invention includes:

[0019] figure 1 It is a reverse bottom view of an airport luggage conveyor rack.

[0020] The airport luggage conveyor rack includes: an end beam bracket, the end beam bracket adopts a cuboid structure, and the end beam bracket is made of stainless steel or cast iron material, wherein the number of end beam brackets is 4, forming a word shape, Between two adjacent end beam brackets, they are connected together by rivets.

[0021] Two intermediate brackets are set between the mouth-shaped end beams. The intermediate brackets are cuboid structures. A cross bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com