Quartz sand cleaning device

A cleaning device and technology for quartz sand, which are applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of high production of quartz sand, increased demand for acid solution, low cleaning efficiency, etc. To achieve the effect of shortening the acid leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is specifically described below in conjunction with accompanying drawing:

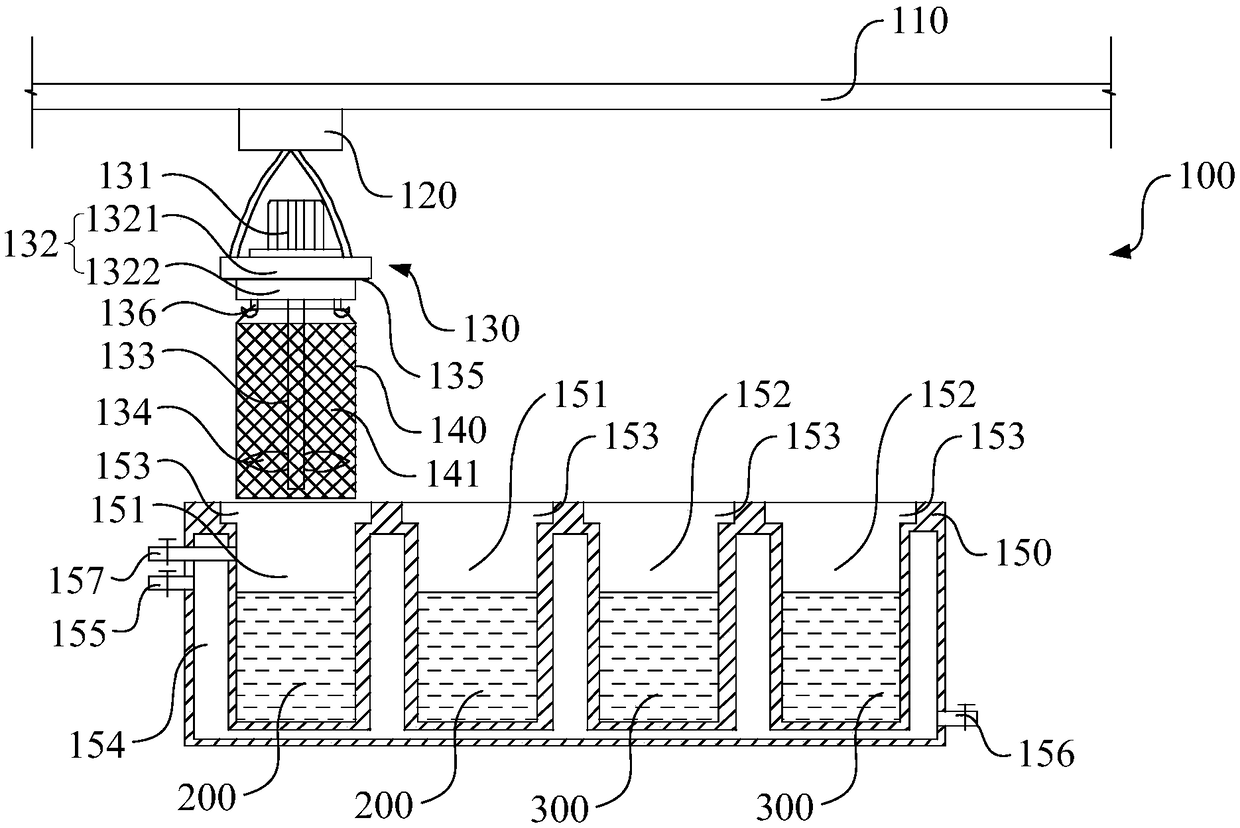

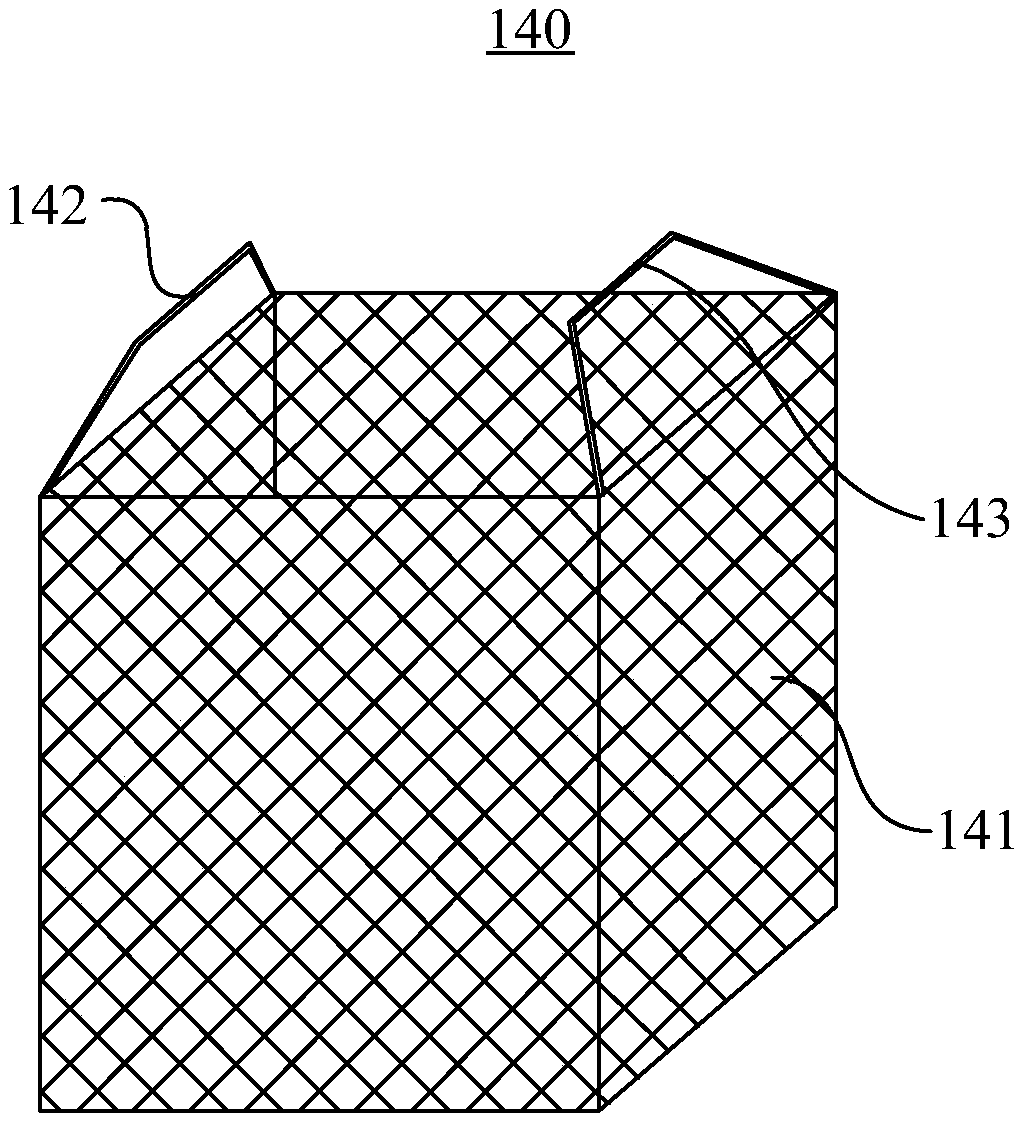

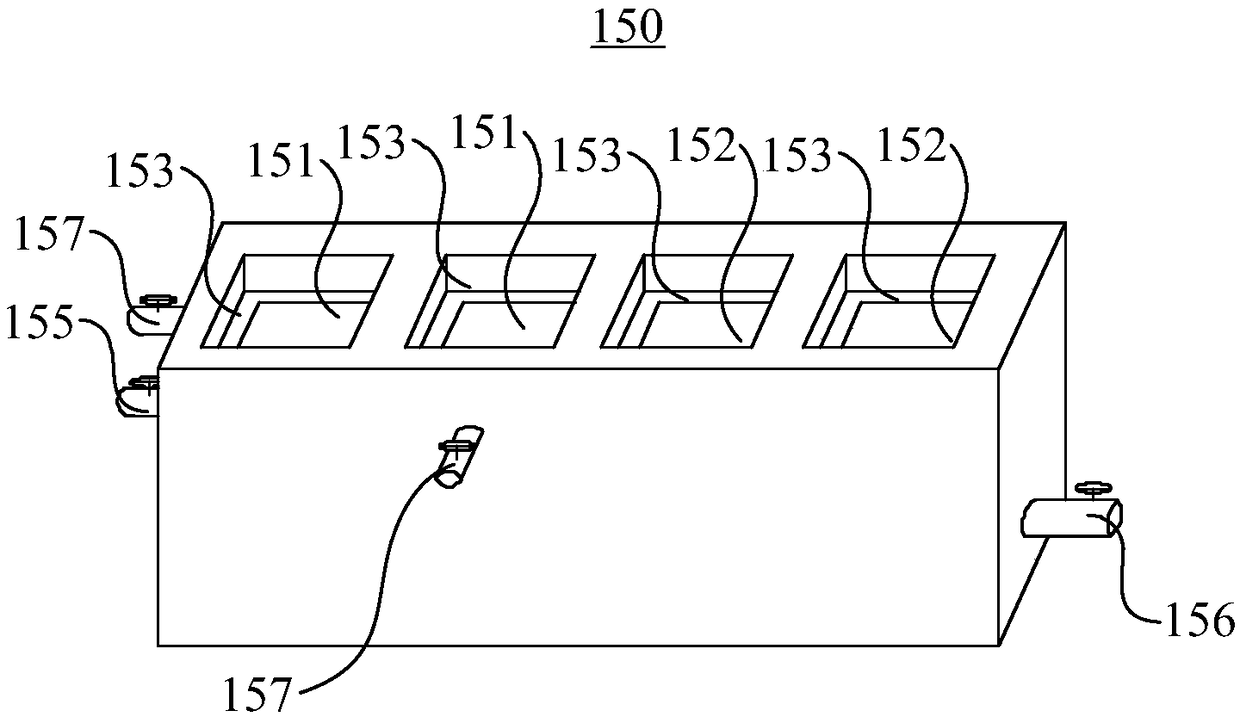

[0028] In one example, please refer to Figure 1 to Figure 3 , a quartz sand cleaning device 100 includes: a support beam 110 , a lifting device 120 , a stirring assembly 130 , a cleaning frame 140 and a cleaning box 150 . The lifting device 120 is slidably mounted on the support beam 110 . The stirring assembly 130 comprises a stirring cover 132, a rotating motor 131 and a stirring shaft 133, the stirring cover 132 is connected with the output end of the lifting device 120, the rotating motor 131 is mounted on the stirring cover 132, the stirring shaft 133 and the output end of the rotating motor 131 transmission connection, and the stirring shaft 133 is set through the stirring cover 132 . The cleaning frame 140 is detachably installed on the stirring cover 132 , and the cleaning frame 140 is used for loading quartz sand, and the cleaning frame 140 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com