Preparation method of zirconium oxide-based adsorbing photocatalyst and photocatalyst

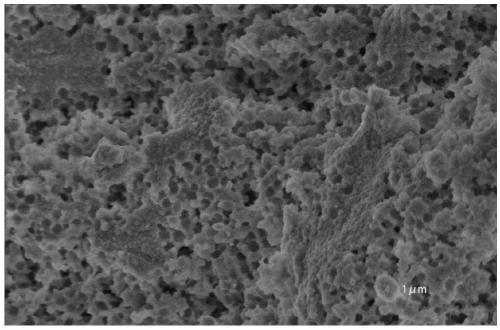

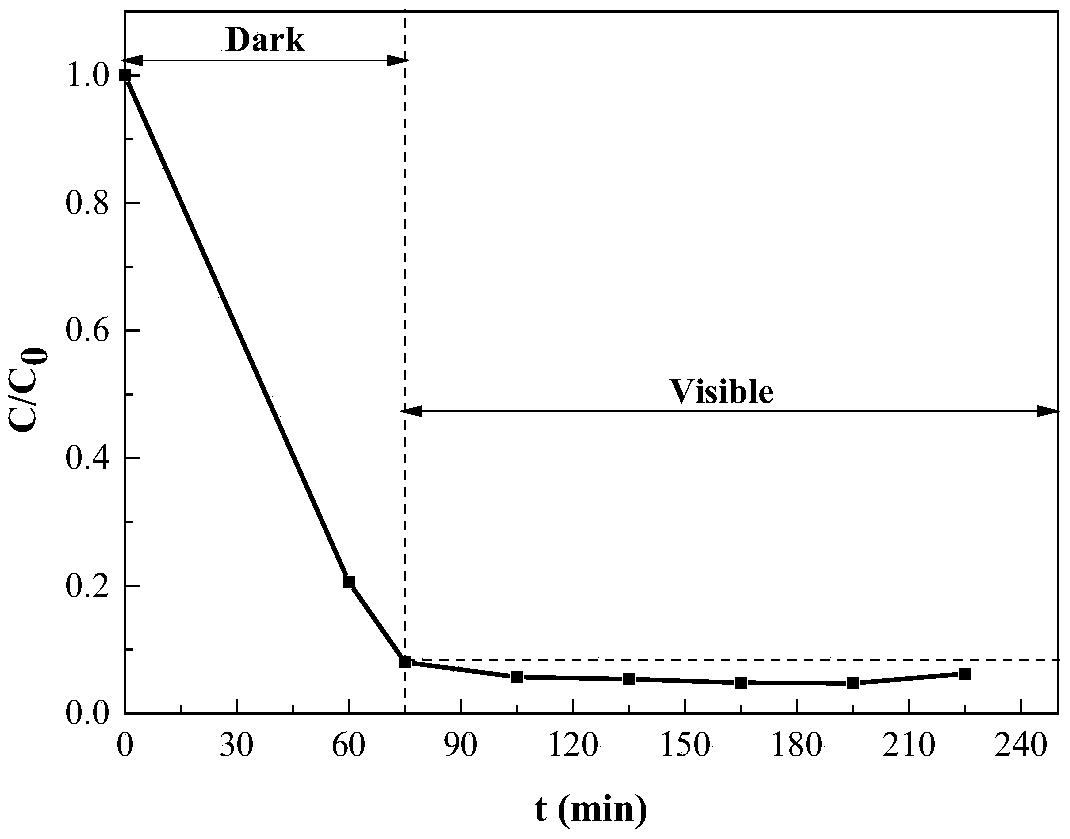

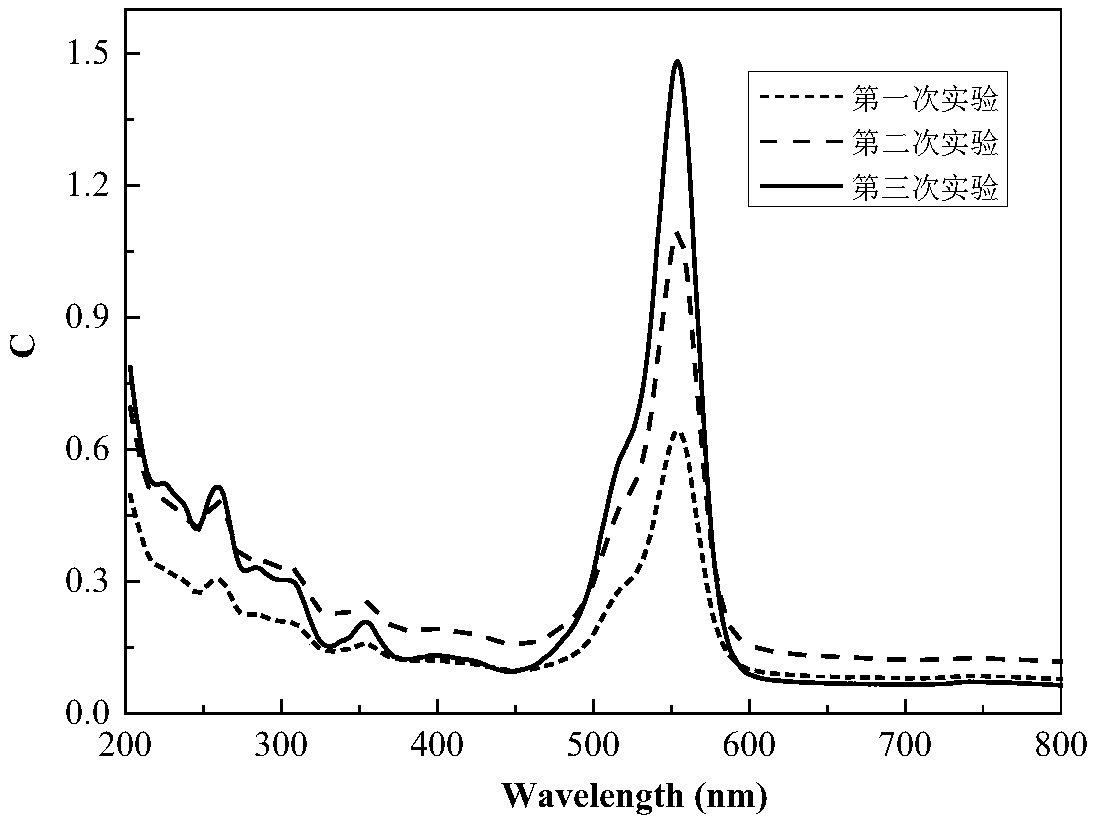

A photocatalyst, zirconia-based technology, used in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. The preparation method is complex and other problems, to achieve the effect of good reusability, high stability and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Configuration of PS ball suspension: add 6mL styrene and 0.2mL α-methacrylic acid to 100mL deionized water, heat and stir in an oil bath to 75°C, stabilize for five minutes, add 0.14g potassium persulfate, continue Stir for 8h.

[0037] (2) Configuration of the zirconium oxychloride precursor solution: according to the mass ratio of 1:1, take a certain mass of citric acid and zirconium oxychloride for use, and dissolve the citric acid and zirconium oxychloride in deionized water to obtain zirconium oxychloride precursor solution, magnetically stirred for 10-30min.

[0038] (3) Configuration of ethyl orthosilicate solution: Calculate the required amount of ethyl orthosilicate according to the molar ratio of zirconium oxychloride to ethyl orthosilicate 0.5:3, and measure a certain amount according to the volume ratio of 1:2 volume of tetraethyl orthosilicate and absolute ethanol, mix evenly, and magnetically stir for 30 minutes.

[0039] (4) Configuration of the sil...

Embodiment 2

[0047] (1) Configuration of PS sphere suspension: add 5mL styrene and 0.2mL α-methacrylic acid to 100mL deionized water, heat and stir in an oil bath to 75°C, stabilize for five minutes, add 0.14g potassium persulfate, continue Stir for 8h.

[0048] (2) Configuration of the zirconium oxychloride precursor solution: according to the mass ratio of 1:1.5, a certain mass of citric acid and zirconium oxychloride were weighed for use, and the citric acid and zirconium oxychloride were dissolved in deionized water to obtain The zirconium oxychloride precursor solution was magnetically stirred for 30 minutes.

[0049] (3) Configuration of ethyl orthosilicate solution: Calculate the required amount of ethyl orthosilicate according to the molar ratio of zirconium oxychloride to ethyl orthosilicate 0.1:3, according to the volume ratio of 1:1-1:4 Measure a certain volume of tetraethyl orthosilicate and absolute ethanol, mix evenly, and stir magnetically for 30 minutes.

[0050] (4) Conf...

Embodiment 3

[0054] (1) Configuration of PS ball suspension: add 6mL styrene and 0.25mL α-methacrylic acid to 100mL deionized water, heat and stir in an oil bath to 75°C, stabilize for five minutes, add 0.14g potassium persulfate, continue Stir for 8h.

[0055] (2) Configuration of the zirconium oxychloride precursor solution: according to the mass ratio of 2:1, take a certain mass of citric acid and zirconium oxychloride respectively for use, and dissolve the citric acid and zirconium oxychloride in deionized water to obtain The zirconium oxychloride precursor solution was magnetically stirred for 30 minutes.

[0056] (3) Configuration of ethyl orthosilicate solution: Calculate the required amount of ethyl orthosilicate according to the molar ratio of zirconium oxychloride to ethyl orthosilicate 0.5:3, according to the volume ratio of 1:1-1:4 Measure a certain volume of tetraethyl orthosilicate and absolute ethanol, mix evenly, and stir magnetically for 30 minutes.

[0057] (4) Configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com