Hyaluronic acid essence and preparation method thereof

A technology of hyaluronic acid and sodium hyaluronate, which is used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations and other directions, can solve the problems of high price and short moisturizing time, and achieves reduction of water loss, prolonged moisturizing time, less sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

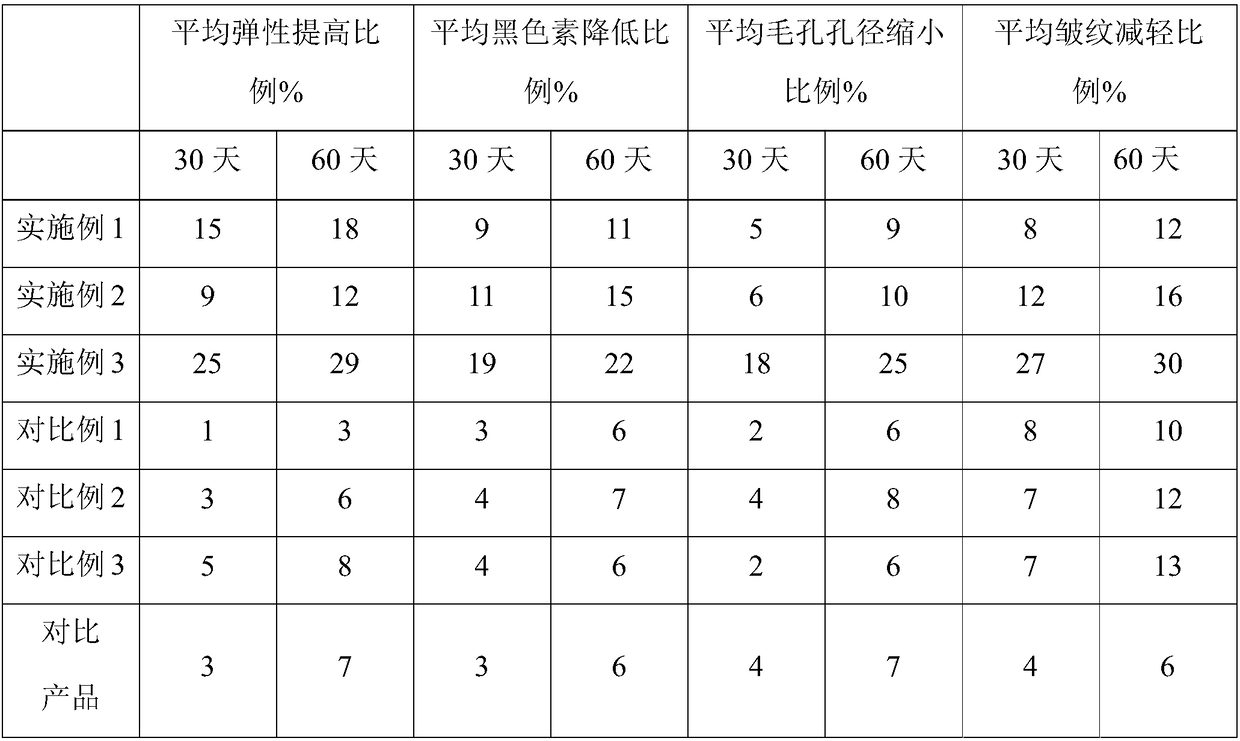

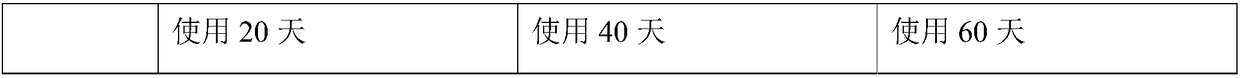

Examples

Embodiment 1

[0024] A hyaluronic acid essence, comprising the following components in weight percent: 0.01% sodium hyaluronate, 0.01% hydrolyzed sodium hyaluronate, 0.01% acetylated sodium hyaluronate, and 0.1% sodium hyaluronate cross-linked polymer , moisturizing agent 0.1%, soothing and repairing agent 0.1%, stabilizer 0.1%, and the balance is purified water.

[0025] Wherein, the molecular weight of sodium hyaluronate is 60kDa.

[0026] Hydrolyzed sodium hyaluronate has a molecular weight of 10kDa.

[0027] The humectant is polyglutamic acid and 1,3-butanediol, and the weight ratio of the two is 2:1.

[0028] The soothing and repairing agent is glycerol glucoside.

[0029] The stabilizer is 1,2-pentanediol and xinthrone, and the weight ratio of the two is 1:2.9.

[0030] The preparation method of the above-mentioned hyaluronic acid essence comprises the following steps: (1) adding purified water and stirring after weighing sodium hyaluronate, hydrolyzed sodium hyaluronate, acetylate...

Embodiment 2

[0034] A hyaluronic acid essence, comprising the following components in weight percentage: 1.0% sodium hyaluronate, 1.0% hydrolyzed sodium hyaluronate, 1.0% acetylated sodium hyaluronate, 10% sodium hyaluronate cross-linked polymer , moisturizing agent 15%, soothing and repairing agent 5%, stabilizer 5%, and the balance is purified water.

[0035] Wherein, the molecular weight of sodium hyaluronate is 1000kDa.

[0036] Hydrolyzed sodium hyaluronate has a molecular weight of 3kDa.

[0037] The moisturizing agent is polyglutamic acid and Luba gum oil, and the weight ratio of the two is 3:1.

[0038] The soothing and repairing agent is purslane extract.

[0039] The stabilizer is 1,2-pentanediol and xinthrone, and the weight ratio of the two is 1:1.6.

[0040] The preparation method of this sodium hyaluronate essence is the same as in Example 1.

Embodiment 3

[0042] A hyaluronic acid essence, comprising the following components in weight percentage: 0.3% sodium hyaluronate, 0.1% hydrolyzed sodium hyaluronate, 0.1% acetylated sodium hyaluronate, 3% sodium hyaluronate cross-linked polymer , moisturizing agent 9.3%, soothing repair agent 2.5%, stabilizer 2.3%, and the balance is purified water.

[0043] Wherein, the molecular weight of sodium hyaluronate is 70kDa.

[0044] Hydrolyzed sodium hyaluronate has a molecular weight of 4kDa.

[0045] The humectant is polyglutamic acid, 1,3-butanediol, reed gum oil, betaine and reed gum oil, and the weight ratio is 2:2:1:1:1.

[0046]The soothing and repairing agent is purslane extract.

[0047] The stabilizer is 1,2-pentanediol and xinthrone, and the weight ratio of the two is 1:3.

[0048] The preparation method of this sodium hyaluronate essence is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com